How Oil Refinery Works Overview Of Oil Refinery

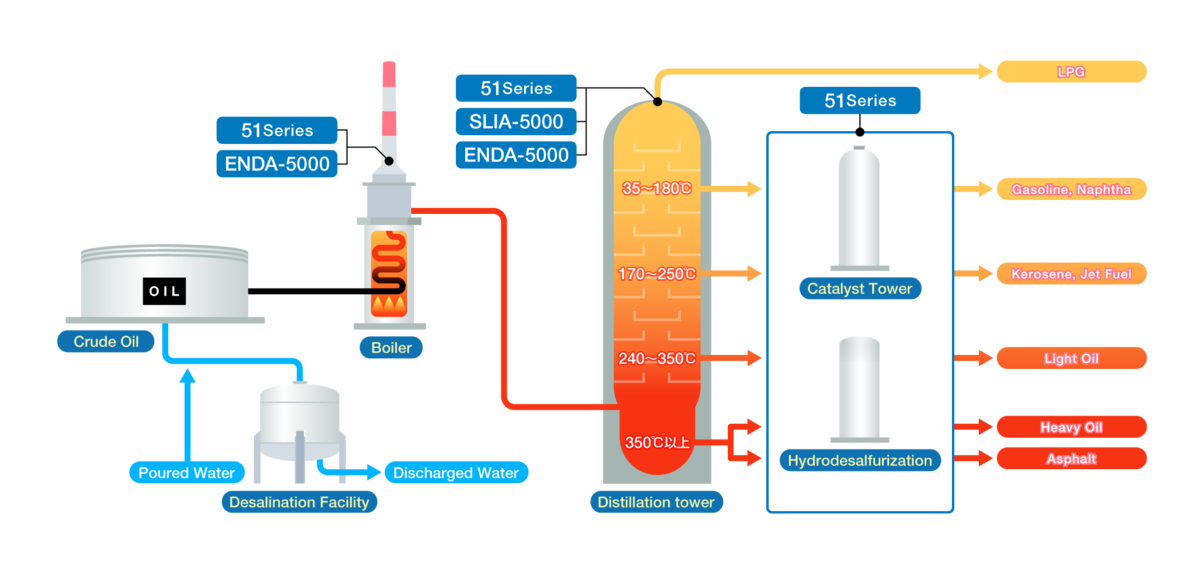

Oil Refinery Improving Efficiency And Process Management Horiba To make gasoline, refinery technicians carefully combine a variety of streams from the processing units. octane level, vapor pressure ratings, and other special considerations determine the gasoline blend. storage. both incoming crude oil and the outgoing final products are stored temporarily in large tanks on a tank farm near the refinery. An oil refinery runs 24 hours a day, 365 days a year, and requires a large number of employees. refineries come offline or stop working for a few weeks each year to undergo seasonal maintenance.

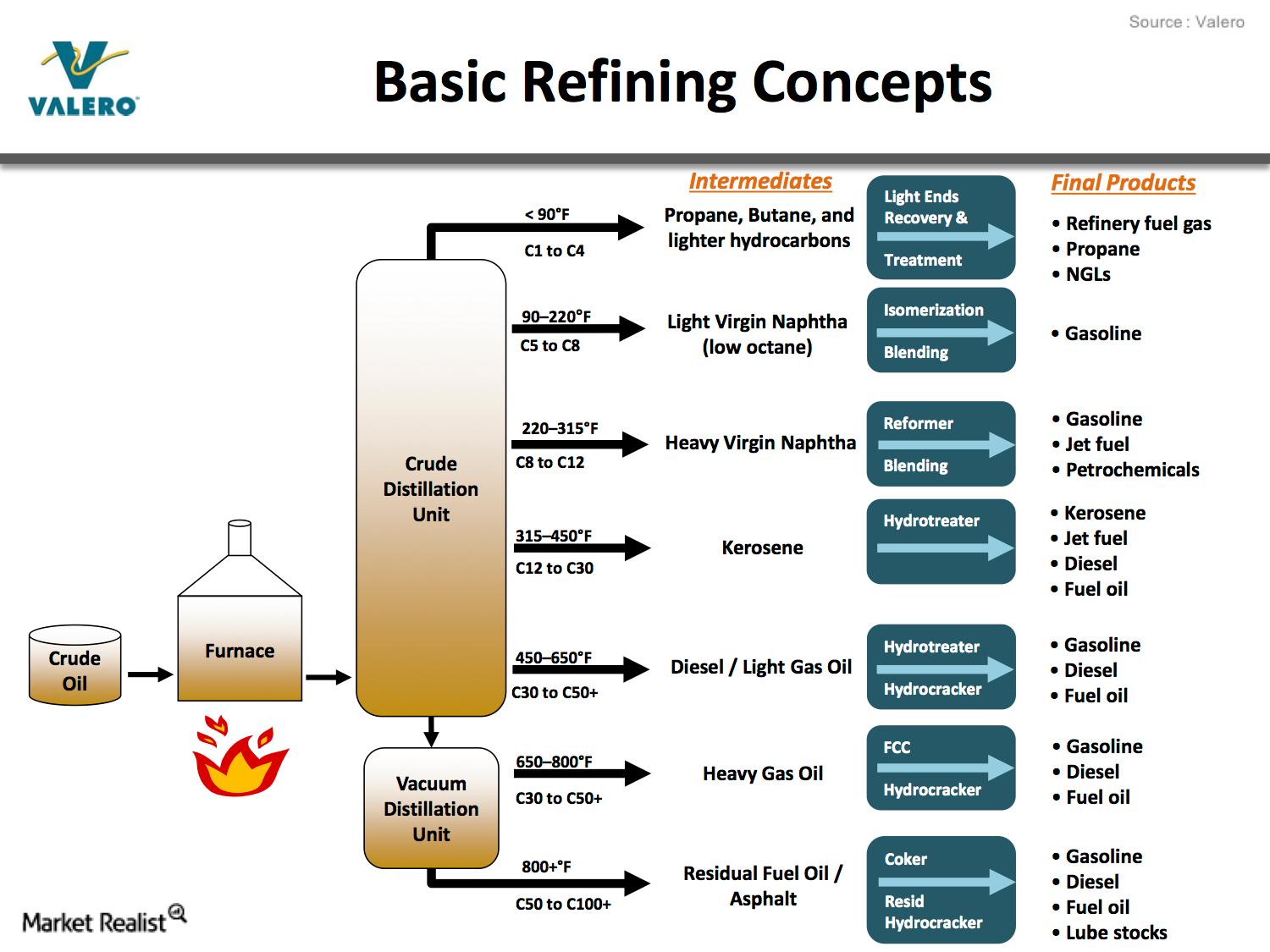

What Is The Process Of Crude Oil Refining An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as liquefied petroleum gas (lpg), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils. [1][2][3] refineries and petroleum. Crude oil refineries employ some of the united states’ top scientists, engineers, and safety professionals to ensure that products are produced efficiently and safely. us refineries process about 17 million barrels of crude oil a day. refinery configurations vary, but us refineries are undeniably some of the world’s most sophisticated. Distillation of kerosene and naphtha. the refining of crude petroleum owes its origin to the successful drilling of the first oil wells in ontario, canada, in 1858 and in titusville, pennsylvania, u.s., in 1859. prior to that time, petroleum was available only in very small quantities from natural seepage of subsurface oil in various areas.

Illustration Of A Crude Oil Refining Stages Of Processing Crude Oil On Crude oil refineries employ some of the united states’ top scientists, engineers, and safety professionals to ensure that products are produced efficiently and safely. us refineries process about 17 million barrels of crude oil a day. refinery configurations vary, but us refineries are undeniably some of the world’s most sophisticated. Distillation of kerosene and naphtha. the refining of crude petroleum owes its origin to the successful drilling of the first oil wells in ontario, canada, in 1858 and in titusville, pennsylvania, u.s., in 1859. prior to that time, petroleum was available only in very small quantities from natural seepage of subsurface oil in various areas. In this article, we'll examine the chemistry and technology involved in refining crude oil to produce all of these different things. craig freudenrich, ph.d. "how oil refining works" 1 january 1970. despite the dangers, oil refineries are essential to society in its current form. learn how crude oil is converted into everything from butane to. Oil refining separates everything into useful substances. chemists use the following steps: the oldest and most common way to separate things into various components (called fractions), is to do it using the differences in boiling temperature. this process is called fractional distillation. you basically heat crude oil up, let it vaporize and.

Fsc 432 Refinery Flow Chart Youtube In this article, we'll examine the chemistry and technology involved in refining crude oil to produce all of these different things. craig freudenrich, ph.d. "how oil refining works" 1 january 1970. despite the dangers, oil refineries are essential to society in its current form. learn how crude oil is converted into everything from butane to. Oil refining separates everything into useful substances. chemists use the following steps: the oldest and most common way to separate things into various components (called fractions), is to do it using the differences in boiling temperature. this process is called fractional distillation. you basically heat crude oil up, let it vaporize and.

Comments are closed.