Hot Dip Galvanizing Dipping Process In Action

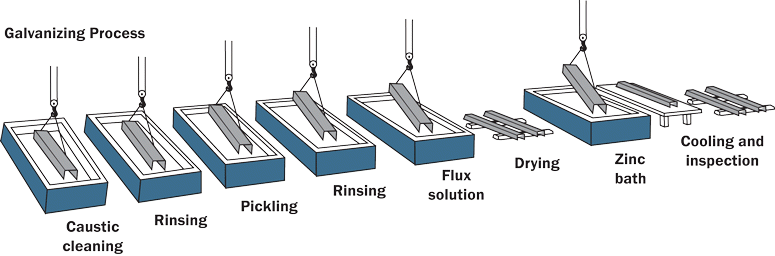

Hot Dip Galvanizing Dipping Process In Action Youtube Watch the actual dipping process in hot dip galvanizing.the formation of galvanized coating on the steel surface is process of metalurgically bonding of iro. Testing methods and interpretation of results can be found in the inspection section of this site, as well as in the inspection course, and inspection of hot dip galvanized steel products. the hot dip galvanizing (hdg) process consists of three basic steps: surface preparation galvanizing inspection surface preparation surface preparation is….

Hot Dip Galvanizing The Ultimate Guide Step 2: galvanizing. when steel is entirely immersed in a bath (kettle) of molten zinc, the galvanizing step of the process happens. the bath chemistry must be at least 98% pure zinc and kept at a temperature of around 850 °f (450 °c), according to the specifications. the crane hoist lowers the steel at an angle. Hot dip galvanizing to astm a123 fact sheet hot dip galvanizing (hdg) is the process of dipping fabricated steel into a kettle or vat containing molten zinc. while the steel is in the kettle, the iron in the steel metallurgically reacts with the molten zinc to form a tightly bonded alloy coating that provides superior corrosion protection to steel. The hot dip galvanizing process protects metals like steel and aluminum from corrosion. it involves immersing pieces in molten zinc, ensuring a coated and protected surface. applied in construction, automotive, and white goods industries. the hot dip galvanizing process is a widely used technique in the metallurgical industry for protecting. For decades, hot dip galvanizing has been used as a means of corrosion protection, but today, many architects, engineers, and owners specify hot dip galvaniz.

Hot Dip Galvanizing Process Azz Uses A Proprietary Formulation The hot dip galvanizing process protects metals like steel and aluminum from corrosion. it involves immersing pieces in molten zinc, ensuring a coated and protected surface. applied in construction, automotive, and white goods industries. the hot dip galvanizing process is a widely used technique in the metallurgical industry for protecting. For decades, hot dip galvanizing has been used as a means of corrosion protection, but today, many architects, engineers, and owners specify hot dip galvaniz. Hot dip galvanization. hot dip galvanization is a form of galvanization. it is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 450 °c (842 °f). when exposed to the atmosphere, the pure zinc (zn) reacts with oxygen (o 2. Issue 1 |hot dip galvanizing properties and process guide june 2021 introduction hot dip galvanizing protects steel from corrosion by providing a tough metallurgically bonded zinc envelope, which completely covers the steel surface and seals it from the corrosive action of its environment. the hot dip galvanized coating provides.

Hot Dipping Industrial Process Britannica Hot dip galvanization. hot dip galvanization is a form of galvanization. it is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 450 °c (842 °f). when exposed to the atmosphere, the pure zinc (zn) reacts with oxygen (o 2. Issue 1 |hot dip galvanizing properties and process guide june 2021 introduction hot dip galvanizing protects steel from corrosion by providing a tough metallurgically bonded zinc envelope, which completely covers the steel surface and seals it from the corrosive action of its environment. the hot dip galvanized coating provides.

Comments are closed.