Heavy Crude Oil Refining

What Is The Process Of Crude Oil Refining The u.s. refining complex is advanced and capable of refining heavier, more sour crude oils, which generally cost less than lighter, sweeter grades of crude oil. refinery crude oil slates—the mix of crude oil grades that a refinery can process into petroleum products such as gasoline and diesel—have become lighter over time. in 2005, the. Heavy crude refining techniques may require more energy input [citation needed] though, so its environmental impact is presently more significant than that of lighter crude if the intended final products are light hydrocarbons (gasoline motor fuels). on the other hand, heavy crude is a better source for road asphalt mixes than light crude.

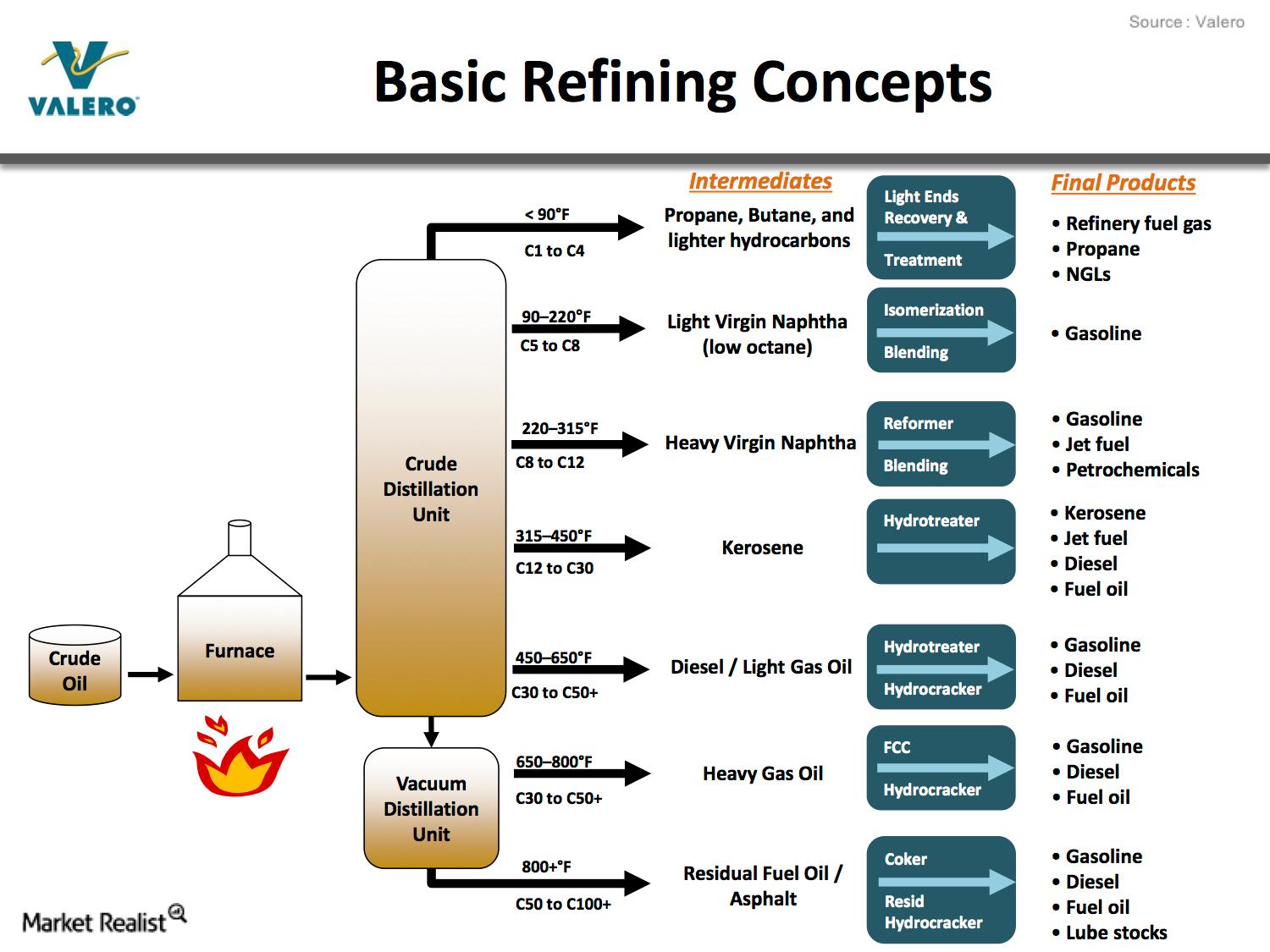

Illustration Of A Crude Oil Refining Stages Of Processing Crude Oil On Crude oil imports from canada, which consist of mostly heavy crude oil, have increased by 67% since 2011 because of increased canadian production. crude oil imports from canada have accounted for a greater share of refinery inputs in the midwest and rocky mountain regions, leading to heavier refinery crude slates in these regions. The total volume of products that refineries produce (output) is greater than the volume of crude oil that refineries process (input) because most of the products they make have a lower density than the crude oil they process. this increase in volume is called processing gain. the average processing gain at u.s. refineries was about 6.3% in 2023. Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as liquefied petroleum gas (lpg), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils. [1][2][3] refineries and petroleum. 4. heavy crude oil refining. the processing of heavy oils in refineries, especially in the existing refineries, presents many difficulties due to their unfavorable characteristics. due to very low h c ratios, the yields of straight run gasoline, kerosene, and diesel are very poor due to high levels of heavier components such as asphaltenes.

Petroleum Refining Processes Explained Simply Youtube Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as liquefied petroleum gas (lpg), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils. [1][2][3] refineries and petroleum. 4. heavy crude oil refining. the processing of heavy oils in refineries, especially in the existing refineries, presents many difficulties due to their unfavorable characteristics. due to very low h c ratios, the yields of straight run gasoline, kerosene, and diesel are very poor due to high levels of heavier components such as asphaltenes. A decade ago, 158 refineries operated in the united states and its territories and sporadic refinery outages led many policy makers to advocate new refinery construction. fears that crude oil production was in decline also led to policies promoting alternative fuels and increased vehicle fuel efficiency. since the summer 2008 peak in crude oil. The heavier and complex molecules of asphaltenes with low h c ratios present many technological challenges during the refining of the crude oil, such as heavy coking on catalysts. hydrogen addition and carbon removal are the two approaches used to improve the recovery of value added products such as gasoline and diesel.

Comments are closed.