Hdpe Multi Layer Pipe Production Line

Hdpe Multi Layer Pipe Production Line The hdpe pipe production line adopts thespecialized high efficient wear resistant extruder for middle layer, which ensures high speed extrusion and guarantee the long service life of extruder while using recycled material. Sai machine tools hdpe pe pipe production line: a feature packed powerhouse for efficiency and quality. – requires low space both lengthwise and width wise (180feetx15feet). – 16 to 19 tonnes per day production in 63, 75, 90, 110mm dia pipe coil. – electrical production cost 0.25 to 0.27 units per kg. (guaranteed).

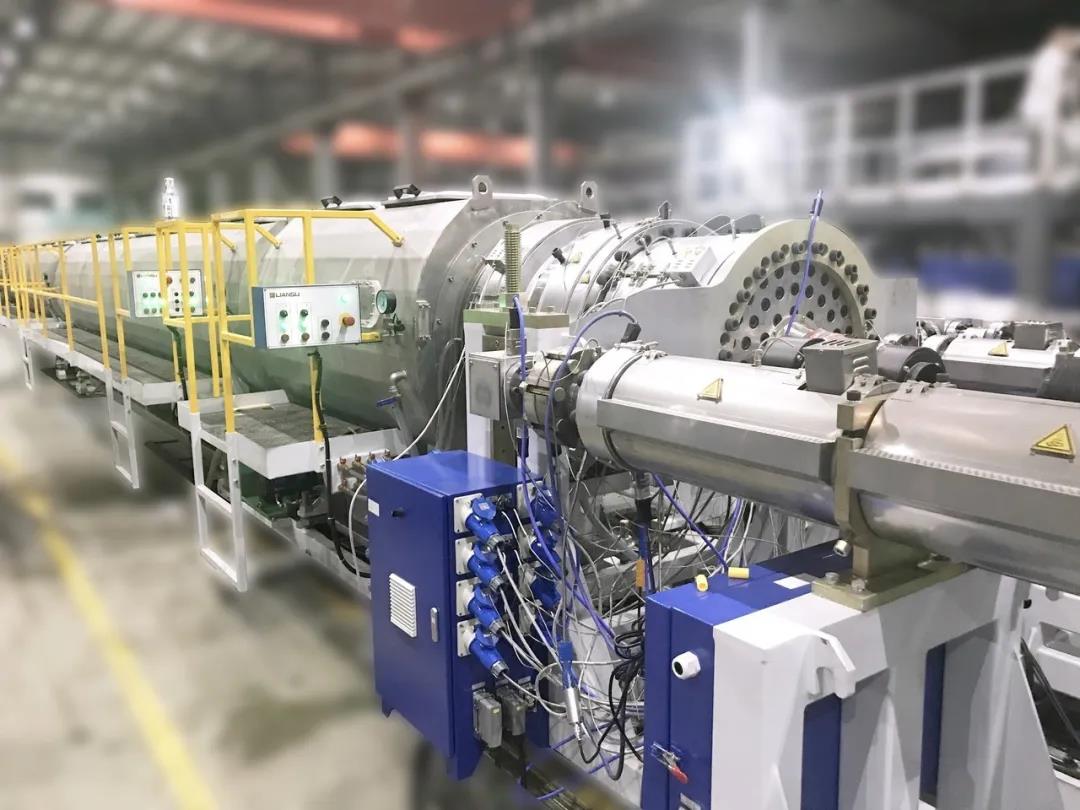

Hdpe Multi Layer Pipe Production Line Multi layer hdpe pipe production line. below pipe production line is used to make two layer or three layer type hdpe pipes. multi layer co extrusion technology is offered, because of cusotmer's and market requirements, such as recycled material used for production cost reduced and also high requirements on produced pipe quality, and different raw material with color difference or add different. The new project cases in june, we would like to share two models of multi layer extrusion line : lsp 160 hdpe 4 layers coextrusion pipe extrusion line · size range :Ø32—Ø160mm · product structure:4 layers,a b a external layer coextrusion · capacity:520 570 kg h. lsp 1200 hdpe 4 l ayers c oextrusion solid pipe extrusion line. 20 315mm hdpe multi layer pipe production line screw with 40 long l d ratio screw bush, output 350 ~ 1500kg h. available pipe head range from pipe size 20mm ~1200mm. Product advantage. the extruder adopts large l d ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving. the die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production.

Hdpe Multi Layer Pipe Production Line 20 315mm hdpe multi layer pipe production line screw with 40 long l d ratio screw bush, output 350 ~ 1500kg h. available pipe head range from pipe size 20mm ~1200mm. Product advantage. the extruder adopts large l d ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving. the die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production. Multi layer hdpe ppr pipe production line. features of hdpe ppr pipe extrusion machine . 1. equipped with polyolefin purposed single screw extruder; it has the characters of quick plasticizing, high efficiency and so on. We offer a wide range of extrusion lines for pipes ranging from ¼” (6mm) – 25” (630mm). drts offers multi layer pipe production lines with the most advanced technology to assure high efficiency, high accuracy, and top quality pipe production.

Comments are closed.