Grp Pipe Jointing

Grp Pipe Jointing Overview of grp pipes. grp pipes or glass reinforced plastics pipes are composite material pipes consisting of a polymer matrix that is reinforced with glass fibres. they have very high corrosion resistance ability and are thus used widely for low temperature corrosion resistant applications. in recent times, grp pipes are slowly replacing. Adhesively bonded area by using epoxy glue between pipe and coupling obtains very strong joint which will be fully resisted against pipeline tensile forces. grp flanges. in special conditions, pipes can be joined with grp flanges. for joining two grp flanges over 300 mm diameter, one flange with gasket groove is enough to sealing. standard bolt.

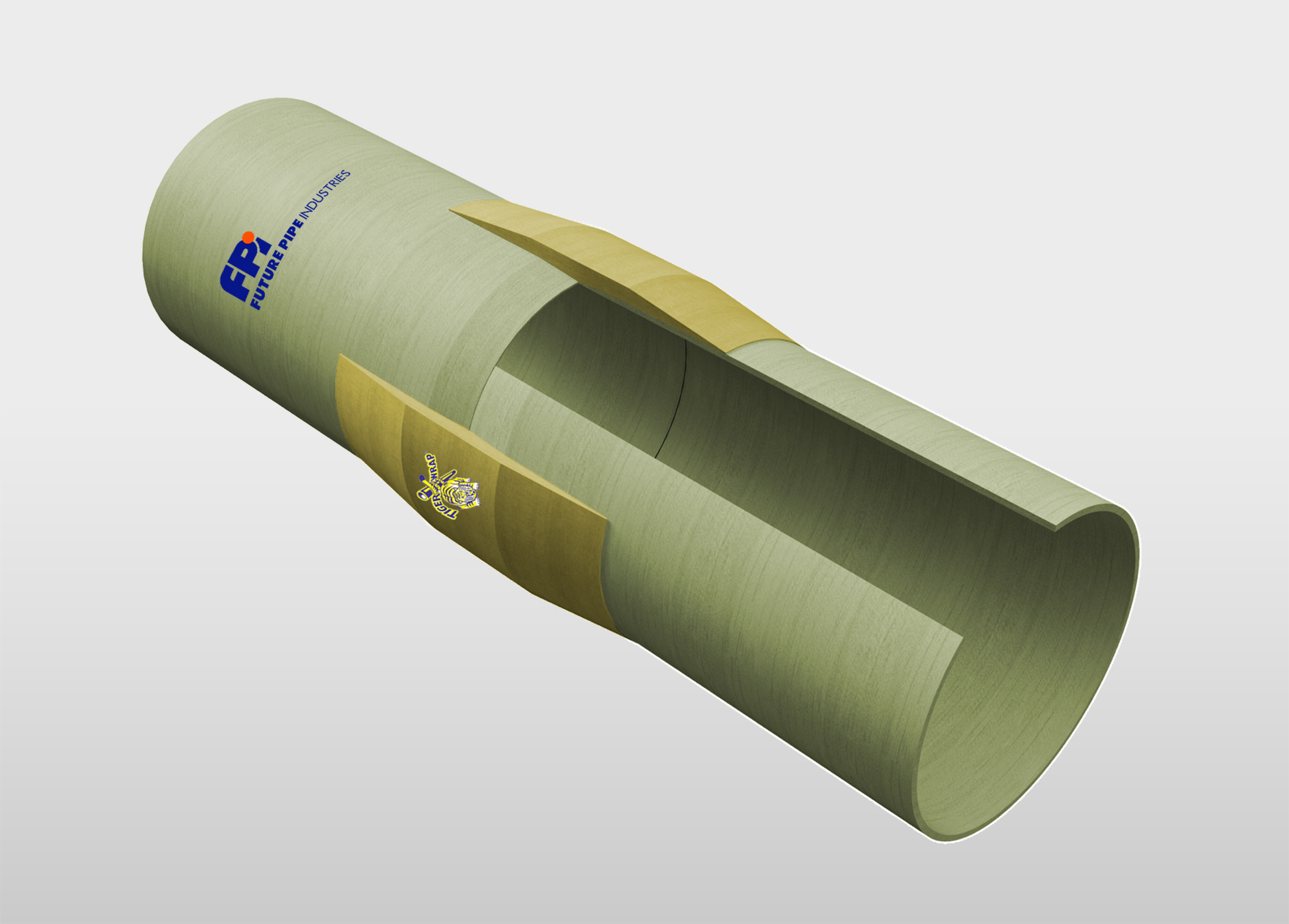

Grp Pipe Jointing Gre pipe lamination butt joint tutorial. this quick guide demonstrates how to perform butt joints using ota fiberglass pipe tools. the whole butt and wrap joint fiberglass process including the lamination for rtr grp gre grup and other frp pipes on site. no matter the type of pipe its origin, this easy to follow tutorial as well as the video below will help explain all about lamination butt. 4.1 lamination joint butt wrap joint it is recommended that the pipe manufacturer provides assistance for this type of joint. fig. 2: typical butt wrap joint profile the below procedure describes the steps to be followed for field joint lamination of grp pipes (fig.3a fig. 3u). preparations • check the pipes routing as per approved drawings,. Internal lamination. (applicable only for 900mm & above in condition that the access to the joint internal area is safe and possible). the following steps are to be done inside the pipes: 1. measure a length of 50 mm from the end of each grp pipe. 2. grind the above area to remove the internal liner of the pipe. 3. Step 1: foundation and bearing. the bearing should be dug in such a way that at each point of the coupling, the headrests on the coupling prevent it from hanging and ensure continuous support of the pipe. after the jointing process is completed, the filling and bearing of the coupling area should be made properly.

Grp Pipe Jointing Internal lamination. (applicable only for 900mm & above in condition that the access to the joint internal area is safe and possible). the following steps are to be done inside the pipes: 1. measure a length of 50 mm from the end of each grp pipe. 2. grind the above area to remove the internal liner of the pipe. 3. Step 1: foundation and bearing. the bearing should be dug in such a way that at each point of the coupling, the headrests on the coupling prevent it from hanging and ensure continuous support of the pipe. after the jointing process is completed, the filling and bearing of the coupling area should be made properly. Ulting engineer.for the installation of hobas grp pipes, the relevant stan dards and guidelines such as en 1610 and iso . s 10465 1 apply. hobas offers custom services based on i. dividual advice. for special conditions requiring specific approaches, please do not hesitate to contact our hobas t. Frp pipe installation. to install the pipes, the following procedure can be used, as a function of the type of joint and of the pipe diameter: a) for any type of joint and diameter: lay and align the pipe bars on the bed that has been previously prepared, and perform the junctions inside the trench.

Grp Pipe Jointing Ulting engineer.for the installation of hobas grp pipes, the relevant stan dards and guidelines such as en 1610 and iso . s 10465 1 apply. hobas offers custom services based on i. dividual advice. for special conditions requiring specific approaches, please do not hesitate to contact our hobas t. Frp pipe installation. to install the pipes, the following procedure can be used, as a function of the type of joint and of the pipe diameter: a) for any type of joint and diameter: lay and align the pipe bars on the bed that has been previously prepared, and perform the junctions inside the trench.

Comments are closed.