Get Your Free Rigging Inspection Guide Shorts

Get Your Free Rigging Inspection Guide Shorts Youtube If you're tasked with safety and training in your company, this field reference guide can be used to help you and your team identify damaged and failed riggi. Shackles are crucial components in rigging, often used for connecting various rigging elements. inspect them for any signs of deformation, cracks, or wear. 2. examination of slings: slings bear heavy loads, making their condition vital. check for cuts, abrasions, or damage to the slings, and ensure proper storage. 3.

Get Your Free Online Pocket Rigging Guide American Crane Safety Rigging equipment inspection checklist. minimize potential issues with equipment by using this checklist. it helps you systematically inspect all your rigging hardware, including shackles, hooks, ropes, and more. key features include checks for hardware condition, proper sizing, and locking mechanisms. feel free to add more items to the. Rigging inspection services. osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. call us at 800.362.4601 or click here if you need inspections for. Rigging inspection services. osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. call us at 800.362.4601 or click here if you need inspections for. The most common problems tie back to misuse and abuse and lack of inspection. some of the most common issues we see are: hooks with missing or broken latches. rigging hardware that’s bent, stretched, broken, or chopped in half. items that have been “repaired” or modified through welding.

Rigging Inspection Resources Rigging inspection services. osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. call us at 800.362.4601 or click here if you need inspections for. The most common problems tie back to misuse and abuse and lack of inspection. some of the most common issues we see are: hooks with missing or broken latches. rigging hardware that’s bent, stretched, broken, or chopped in half. items that have been “repaired” or modified through welding. If you're tasked with safety and training in your company, this field reference guide can be used to help you and your team identify damaged and failed rigging equipment. 1:11. the mazzella iti rigging gear inspection field reference guide can be used to train or refresh your team on what damaged or failed equipment looks like, according to. This particular rigging equipment inspection checklist template comes pre built with sections for: the inspection of rigging hardware. the inspection of hooks. inspection of wire rope slings, web slings, round slings and below the hook lifting devices. an inspector and or worker will be guided through these checklist questions which ensures.

Drilling Rig Inspection Checklist Template Free And Customisable If you're tasked with safety and training in your company, this field reference guide can be used to help you and your team identify damaged and failed rigging equipment. 1:11. the mazzella iti rigging gear inspection field reference guide can be used to train or refresh your team on what damaged or failed equipment looks like, according to. This particular rigging equipment inspection checklist template comes pre built with sections for: the inspection of rigging hardware. the inspection of hooks. inspection of wire rope slings, web slings, round slings and below the hook lifting devices. an inspector and or worker will be guided through these checklist questions which ensures.

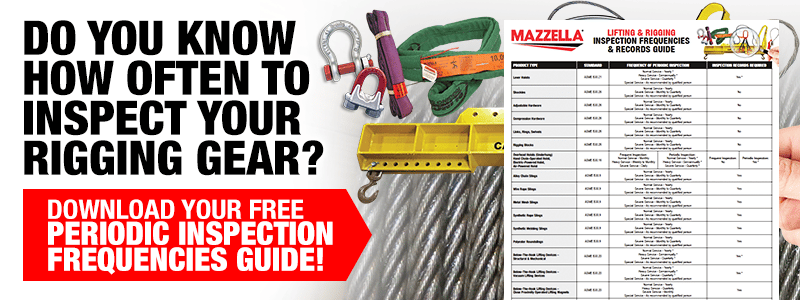

Inspection Frequencies Records Guide For Lifting Rigging Equipment

Comments are closed.