Fresh Water Generator On Ship Seawater Desalination Process

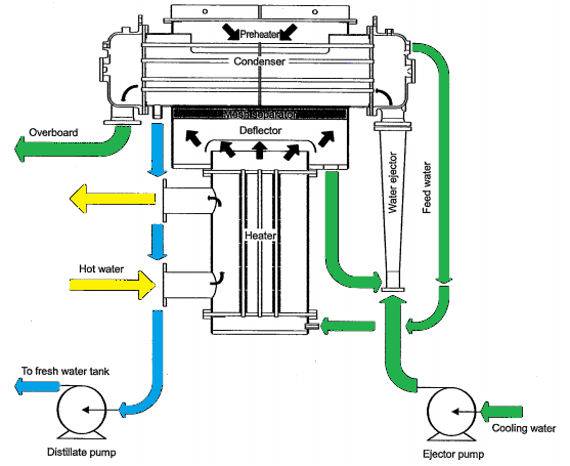

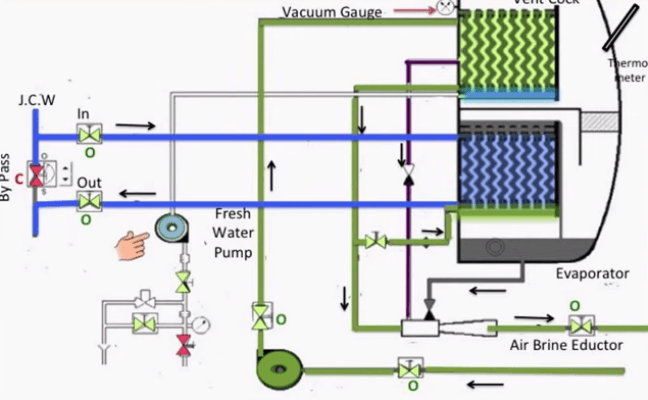

Fresh Water Generator On Ship Seawater Desalination Process The seawater will boil and evaporate at around 40 60 o c due to the vacuum conditions made by the air brine ejector. the water spray and droplets are partly removed from the vapor by the use of the deflector mounted on top of the evaporator. the separated water and droplets fall back to the brine and will be extracted again by the ejector. Open the sea water discharge valve from where the water is sent back to the sea after circulating inside the fresh water generator. close the vacuum valve situated on top of the generator. now start the sea water pump and check the pressure of the pump. the pressure is generally 3 4 bars. wait for the vacuum to build up.

Fresh Water Generator On Ship Seawater Desalination Process 8: fresh water generator troubleshooting. the fresh water generators are crucial devices on ships that convert seawater to freshwater using a process known as desalination. troubleshooting fresh water generator issues is critical to ensuring that drinkable water is available on board. here are some fresh water generator troubleshooting techniques. By doing so, it enhances the freshwater generator’s efficiency and overall performance by minimizing heat transfer resistance. the process of saltwater desalination. the process of saltwater desalination can be broken down into the following steps: pumping seawater into the freshwater generator through a connection to the sea. Seawater desalination process in the world. on top of that it is the only evaporation principle where heat transfer and evaporation are strictly separated. this minimises the risk of scaling and reduces maintenance costs. wärtsilä’s multi stage flash evaporator (msf) is used for producing freshwater from seawater, well water or industrial. Wärtsilä’s single stage desalination (ssd) unit generates high quality freshwater in an energy efficient way. with a capacity from 8 to 35 ton day, it is ideal for converting seawater for use as drinking or technical water onboard ships or offshore installations. the wärtsilä ssd is a state of the art desalination unit that meets the need.

How Do Fresh Water Generators Works On Ships Components Process And Seawater desalination process in the world. on top of that it is the only evaporation principle where heat transfer and evaporation are strictly separated. this minimises the risk of scaling and reduces maintenance costs. wärtsilä’s multi stage flash evaporator (msf) is used for producing freshwater from seawater, well water or industrial. Wärtsilä’s single stage desalination (ssd) unit generates high quality freshwater in an energy efficient way. with a capacity from 8 to 35 ton day, it is ideal for converting seawater for use as drinking or technical water onboard ships or offshore installations. the wärtsilä ssd is a state of the art desalination unit that meets the need. The process of generating fresh water is achieved via distillation. there are three main methods employed for generating fresh water from seawater, these are boiling, evaporating and reverse osmosis (ro). most marine vessels and industrial plants produce fresh water using either evaporators or ro plants. Plate type fresh water generators (fwgs) are essential systems on ships that produce fresh water from seawater through a process called desalination. the bas.

Fresh Water Generator On Ship Seawater Desalination Process The process of generating fresh water is achieved via distillation. there are three main methods employed for generating fresh water from seawater, these are boiling, evaporating and reverse osmosis (ro). most marine vessels and industrial plants produce fresh water using either evaporators or ro plants. Plate type fresh water generators (fwgs) are essential systems on ships that produce fresh water from seawater through a process called desalination. the bas.

Converting Seawater To Freshwater On A Ship Fresh Water Generator

Seawater Desalination Process

Comments are closed.