Freeform Progressive Lens Technology Back Surfacing

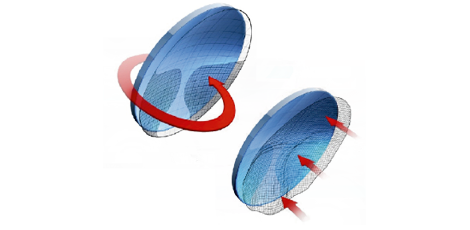

Freeform Progressive Lens Technology Back Surfacing Youtube Free form or digital lens surfacing is an advanced, state of the art surfacing technology. it utilizes highly complex computer algorithms to control a diamond tip lathe that carves the prescription into the back surface of the lens. this allows for precise lens designs that can be tailored to all types of visual demands. Free form technology. free form surfacing, also referred to as direct or digital surfacing, refers to a process that is capable of producing complex surface shapes, including aspheric, atoric and even progressive addition surfaces. a typical process begins by generating the lens surface using a three axis, computer numerically controlled (or.

Progressive Lenses Back Surfacing Vs Front Surfacing Digital An explanation of the difference between back surfacing and front surfacing of progressive lenses in glasses. the benefits of back surfacing are also explain. The variable corridor concept is incorporated into dual surface soft and all back surface hard freeform progressive lens designs. additionally, manufacturers can craft task specific or prioritized software driven lenses using freeform surfacing capabilities that enable prescribers to customize the length of the variable corridor to meet their. Free form technology. free form surfacing, also referred to as direct or digital surfacing, refers to a process that is capable of producing complex surface shapes, including aspheric, atoric and even progressive addition surfaces. a typical process begins by generating the lens surface using a three axis, computer numerically controlled (or. Free form lens surfacing is a modern, state of the art surfacing technology. it utilizes highly complex computer algorithms referencing thousands of data points to control a diamond tip lathe that carves the prescription into the back surface of the lens. this process allows precise lens designs to be tailored to various visual demands.

Lesson Free form technology. free form surfacing, also referred to as direct or digital surfacing, refers to a process that is capable of producing complex surface shapes, including aspheric, atoric and even progressive addition surfaces. a typical process begins by generating the lens surface using a three axis, computer numerically controlled (or. Free form lens surfacing is a modern, state of the art surfacing technology. it utilizes highly complex computer algorithms referencing thousands of data points to control a diamond tip lathe that carves the prescription into the back surface of the lens. this process allows precise lens designs to be tailored to various visual demands. Freeform lenses are created using advanced digital surfacing technology that allows for unprecedented precision in lens production. unlike traditional lenses, which have a uniform curve across the surface, freeform lenses are customized to each patient’s unique prescription, taking into account the curvature of the eye, the shape of the frame. With free form technology the back surface of the lens can be generated point by point allowing the generation of arbitrary surfaces. thus, using this production technology allows the design providers to calculate lenses based on the individual needs of each user [1]. in progressive lenses, the continuous increment of power.

Freeform Technology Beta Optik Freeform lenses are created using advanced digital surfacing technology that allows for unprecedented precision in lens production. unlike traditional lenses, which have a uniform curve across the surface, freeform lenses are customized to each patient’s unique prescription, taking into account the curvature of the eye, the shape of the frame. With free form technology the back surface of the lens can be generated point by point allowing the generation of arbitrary surfaces. thus, using this production technology allows the design providers to calculate lenses based on the individual needs of each user [1]. in progressive lenses, the continuous increment of power.

Comments are closed.