Flexible Pipe Joint Coupling At Samantha Gregory Blog

Flexible Pipe Joint Coupling At Samantha Gregory Blog The difference is on the inside of the joint in the way that the gasket, groove, and clamp fit together. a rigid clamp permits next to no separation, rotation, or angular movement. but a flexible coupling permits some movement and space without compromising the seal or damaging the pipe. nfpa 13 officially describes how much flexibility is allowed:. When movement forces are induced, the flexible pipe coupling remains a self restrained joint, and the pressure responsive gasket design provides positive sealing even during piping system movement. grooved rigid pipe couplings do not allow for movement, similar to a rigid flanged or welded joint. piping systems joined with grooved rigid pipe.

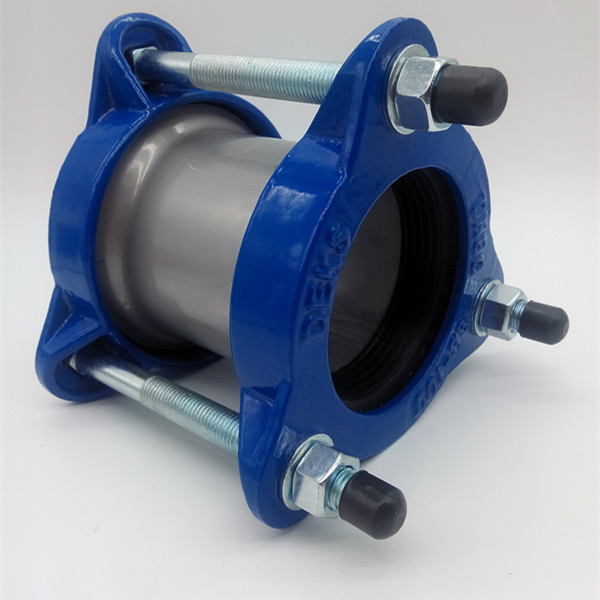

Flexible Pipe Joint Coupling At Samantha Gregory Blog The difference is on the inside of the joint in the way that the gasket, groove, and clamp fit together. a rigid clamp permits next to no separation, rotation, or angular movement. but a flexible coupling permits some movement and space without compromising the seal or damaging the pipe. nfpa 13 officially describes how much flexibility is allowed:. A coupling is a device that joins two or more pipes to maintain continuity. the material used to create this component is similar to those used to construct the pipe infrastructure the coupling connects to. depending on the infrastructure’s needs and the amount of movement it is subjected to, a pipe coupling may be rigid or flexible. Style 31 awwa coupling. provides a rigid or flexible joint on class 53 or higher pipe. optional coatings include orange enamel, coal tar epoxy, organic zinc primer and bituminous. sizes from 3 – 36″ | dn80 – dn900. Designed for service up to 300psi depending on the size, the coupling forms a flexible grooved end pipe joint connection and reduces noise and vibration transmissions in the pipeline. 1. flexible couplings in straight runs should be supported as close to the coupling as possible, or within a distance of 1 6 the span, and evenly spaced. 2.

Flexible Pipe Joint Coupling At Samantha Gregory Blog Style 31 awwa coupling. provides a rigid or flexible joint on class 53 or higher pipe. optional coatings include orange enamel, coal tar epoxy, organic zinc primer and bituminous. sizes from 3 – 36″ | dn80 – dn900. Designed for service up to 300psi depending on the size, the coupling forms a flexible grooved end pipe joint connection and reduces noise and vibration transmissions in the pipeline. 1. flexible couplings in straight runs should be supported as close to the coupling as possible, or within a distance of 1 6 the span, and evenly spaced. 2. Metal flexible pipe connectors, also known as bellows connectors, are ideal for high pressure applications that require high temperature resistance, such as steam or gas systems. these connectors provide excellent pressure, temperature, and corrosion resistance, making them widely used in pump and compressor systems. The gruvlok® fig. 7001 coupling forms a flexible grooved end pipe joint connection with the versatility for a wide range of applications. services include mechanical and plumbing, process piping, mining and oil field piping, and many others. the coupling design supplies optimum strength for working pressures to 1000 psl (69 bar) without.

Comments are closed.