Fillet Weld Using Laser Metal Deposition

Fillet Weld Using Laser Metal Deposition Youtube This video shows how laser metal deposition (lmd) can be used for fillet welds. lmd is typically used to repair or improve wear and corrosion areas on compon. The weld defects of an undercut and humping bead readily occur in efforts to apply high speed gas metal arc (gma) welding for higher productivity. additionally, weld defects and parameters of the bead geometry such as the flank angle affect the fatigue strength of fillet welded joints. the present study investigated bead shape control for high speed fillet welding using hot wire gma laser.

Double Fillet Lap Laser Welding Condition Download Scientific Diagram Moreover, the study revealed the precedence of molten metal under the limitation of the total deposition volume, which depended on the bead width (gap size) of the butt joint single v groove weld. Based on this pilot study, the laser power was varied from 200 w to 800 w and welding speed from 500 mm min to 2500 mm min. similarly, the ranges for wobble parameters were 0.2 mm to 0.8 mm for wobble amplitude and 500 hz to 900 hz for wobble frequency. the details of the parameter combinations are shown in table 2. The shape and size of a weld bead consisting of outer weld surface and inner fusion boundary are important quality and strength attributes in sheet metal welds. the asymmetricity coupled with additional controlling parameters makes it challenging to predict the bead shape in laser arc hybrid fillet lap joints with use of lower order nonlinear analytical mathematical functions. an. Remote laser welded fillet and i seams at overlapped metal sheets are im portant joints for body in white production. under ideal conditions such joints can be created in a weld ing friendly pa (flat) position with a zero gap between the parts. in fig. 1, an example of a fillet welding process incl. a cross section of a typical weld seam at an.

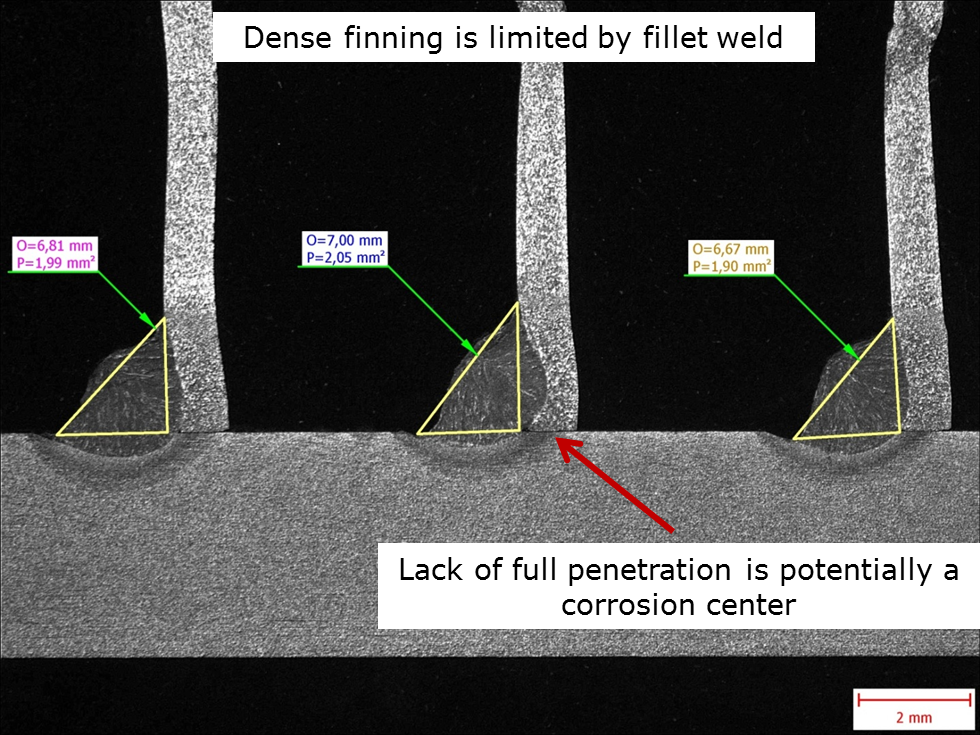

Laser Welding Ams Laser Fin The shape and size of a weld bead consisting of outer weld surface and inner fusion boundary are important quality and strength attributes in sheet metal welds. the asymmetricity coupled with additional controlling parameters makes it challenging to predict the bead shape in laser arc hybrid fillet lap joints with use of lower order nonlinear analytical mathematical functions. an. Remote laser welded fillet and i seams at overlapped metal sheets are im portant joints for body in white production. under ideal conditions such joints can be created in a weld ing friendly pa (flat) position with a zero gap between the parts. in fig. 1, an example of a fillet welding process incl. a cross section of a typical weld seam at an. Numerous researchers have pointed that laser vision sensing plays an essential role in robot welding. laser stripe contains abundant weld characteristics, such as weld position [8], [9], thermal deformation [10], [11] and weld seam path [12], [13], etc. wang et al. [14] proposed a weld seam recognition algorithm for fillet weld, lap weld and butt weld based on laser vision sense, overcoming. The asymmetricity coupled with additional controlling parameters makes it challenging to predict the bead shape in laser arc hybrid fillet lap joints with use of lower order nonlinear analytical.

Comments are closed.