Expansion Joints And Pipe Loops Explained Savree

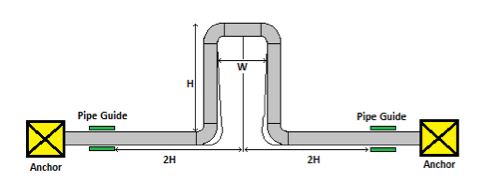

Expansion Joints And Pipe Loops Explained Savree Expansion joints are used if the installation of expansion loops (piping laid in a semi circular shape) is not practical. pipe expansion loop. if thermal expansion of the piping system is not catered for, loads will be transferred to stationary supports and equipment, which may lead them to failing. the problems arising from thermal expansion. Adjustment usually involves being able to rotate the support to align it with the pipe, and or increase or decrease its height marginally to better support the pipe. expansion joints and expansion loops. expansion joints and expansion loops are also used to cater for thermal expansion within piping systems. maintenance requirements associated.

Expansion Joints And Pipe Loops Explained Savree When design conditions exist, where an expansion joint or a pipe loop can be utilized, the major advantages of using an expansion joint are as follows: space is inadequate for a pipe loop with sufficient flexibility. a minimum pressure drop throughout the pipeline is required and the absence of flow turbulence from the elbows and piping is. Piping expansion joints serve various purposes when installed in a piping system. those are: to absorb movement (thermal expansion as well as compression) to relieve system stress and strain. to reduce mechanical noise and vibration. to have a compact design (space constraint) to compensate for misalignment. Expansion joints are available in slip, ball, metal bellows, and rubber bellows configurations. slip type expansion joints (fig. 1) have a sleeve that telescopes into the body. leakage is controlled by packing located between the sleeve and the body. leakage is minimal and can be near zero in many applications. In this table, an expansion joint is compared against a pipe loop. the table shows that a dn 100 expansion joint is in general approximately 37% cheaper than a pipe loop of the same size. if the pipe size is dn 400, an expansion joint solution is approximately 82% cheaper than a pipe loop. the data is calculated on the basis of these conditions.

Types Of Expansion Joints Expansion joints are available in slip, ball, metal bellows, and rubber bellows configurations. slip type expansion joints (fig. 1) have a sleeve that telescopes into the body. leakage is controlled by packing located between the sleeve and the body. leakage is minimal and can be near zero in many applications. In this table, an expansion joint is compared against a pipe loop. the table shows that a dn 100 expansion joint is in general approximately 37% cheaper than a pipe loop of the same size. if the pipe size is dn 400, an expansion joint solution is approximately 82% cheaper than a pipe loop. the data is calculated on the basis of these conditions. 4. expansion joint. this mechanism is often used in tight, enclosed areas where it is difficult to include any expansion loops or offsets. expansion joints are specialized assemblies that act as a shock absorber allowing the pipe to move freely within another pipe while maintaining the necessary seal. Make the piping systems fit the expansion joint. by stretching, compressing, or offsetting the joint to fit the piping, the joint may be overstressed when the system is in service. it is good practice to leave one flange loose until the expansion joint has been fitted into position. make necessary adjustment of loose flange before welding.

Knowing Expansion And Contraction Of Piping Systems Civil Engineering 4. expansion joint. this mechanism is often used in tight, enclosed areas where it is difficult to include any expansion loops or offsets. expansion joints are specialized assemblies that act as a shock absorber allowing the pipe to move freely within another pipe while maintaining the necessary seal. Make the piping systems fit the expansion joint. by stretching, compressing, or offsetting the joint to fit the piping, the joint may be overstressed when the system is in service. it is good practice to leave one flange loose until the expansion joint has been fitted into position. make necessary adjustment of loose flange before welding.

Comments are closed.