Electric Car Cooling System

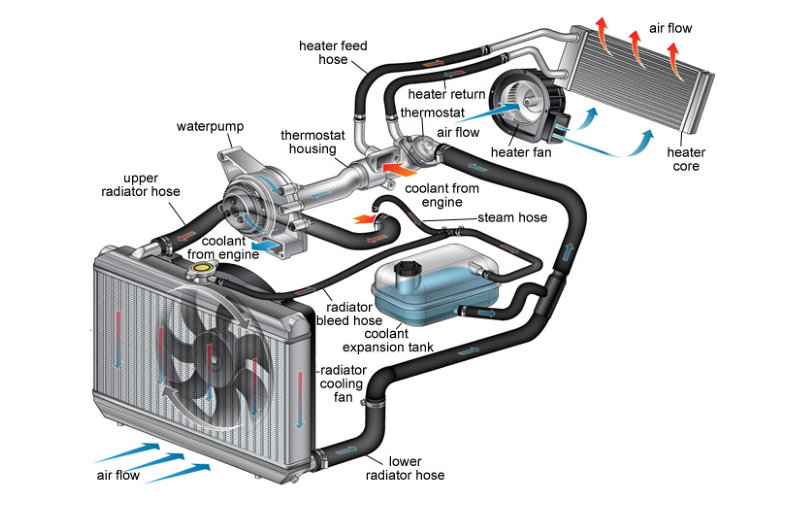

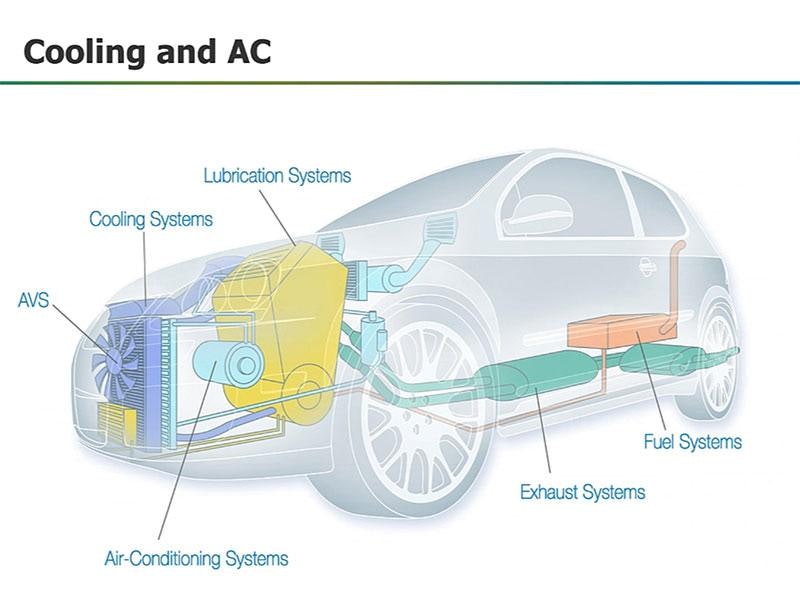

Electric Car Cooling System Diagram The indirect liquid cooling systems for electric vehicles and the conventional internal combustion engine (ice) cooling system are very similar: both circulate coolant throughout a series of metal pipes to transfer heat away from the battery pack or engine. therefore, coolant requirements for indirect liquid cooling systems will be very similar. Electric vehicles also produce heat, but the main component that needs cooling in an ev is the battery. internal combustion engines produce a lot more heat than evs do. but, due to the importance of keeping ev batteries operating at a safe temperature, coolant is also important for electric vehicles. not all electric vehicles use coolant, though.

Electric Car Cooling System Liquid cooling: the premium ev battery cooling systems. think of this as the spa treatment for your battery. a coolant liquid is circulated in the battery cells, absorbing and dissipating heat through a radiator. it’s a more sophisticated, efficient approach for vehicles demanding high performance and longer ranges. As with a gasoline engine’s system, the fluid gets hot as it cools the battery, and is cooled in a heat exchanger – basically a small radiator – and then recirculated in a closed loop. that. The liquid cooling system design facilitates the circulation of specialized coolant fluid. in its journey, the fluid absorbs heat during battery operation and charging processes. subsequently, it transports this heat away from the battery cells and through a heat exchanger. as the fluid cools, the liquid cooling system reintroduces it into the. The shift toward liquid cooling systems in high performance battery applications is a testament to their effectiveness. this trend is not just confined to the automotive industry — similar systems are increasingly used in battery compartment units and electric generators, as well as data centers to manage server generated heat.

Electric Car Bayttery Cooling System Diagram The liquid cooling system design facilitates the circulation of specialized coolant fluid. in its journey, the fluid absorbs heat during battery operation and charging processes. subsequently, it transports this heat away from the battery cells and through a heat exchanger. as the fluid cools, the liquid cooling system reintroduces it into the. The shift toward liquid cooling systems in high performance battery applications is a testament to their effectiveness. this trend is not just confined to the automotive industry — similar systems are increasingly used in battery compartment units and electric generators, as well as data centers to manage server generated heat. This paper addresses current and upcoming trends and thermal management design challenges for electric vehicles and emobility with a specific focus on battery and inverter cooling. liquid cooling is extremely efficient to handle higher heat loads, but systems must be designed to optimize size, weight, performance, reliability, and durability. The ford mustang mach e and f 150 lightning owner's manuals recommend checking the integrity of cooling system hoses, as well as the cooling system level and strength, at six month intervals.

Improved Modeling Of Hybrid Electric Vehicle Cooling System Siemens Eda This paper addresses current and upcoming trends and thermal management design challenges for electric vehicles and emobility with a specific focus on battery and inverter cooling. liquid cooling is extremely efficient to handle higher heat loads, but systems must be designed to optimize size, weight, performance, reliability, and durability. The ford mustang mach e and f 150 lightning owner's manuals recommend checking the integrity of cooling system hoses, as well as the cooling system level and strength, at six month intervals.

Comments are closed.