Efw Pipe Vs Seamless Pipe What S The Differences

Efw Pipe Vs Seamless Pipe What S The Differences Efw pipe is made from welded plates, while the seamless pipe is made from a single piece of metal. seamless pipe is stronger than efw pipe and can withstand higher pressures. seamless pipe is also available in a wider range of sizes than efw pipe. however, efw pipe can be customized to meet the customer’s needs, while seamless pipe cannot be. By understanding the differences between seamless and efw pipes, you can make informed decisions that align with your project’s needs, ensuring optimal performance, safety, and cost efficiency. whether you are involved in construction, energy, or industrial processes, selecting the right type of pipe is crucial to the success of your operations.

Efw Pipes Vs Seamless Pipes Advantages And Disadvantages 2. seamless pipe meaning. a seamless pipe is a pipe without a seam or a weld joint. seamless pipes are thought to be able to withstand higher pressure, higher temperatures, and corrosive environments. seamless pipes are made by process of piercing round billets of steel and stretching the steel out into a seamless pipe. Efw and seamless pipes have their advantages and disadvantages, but industry specific requirements determine which type of pipe is better suited. when cost is a crucial factor, efw pipes are a more economical option, but seamless pipes are a better choice when quality and durability are a priority. it is essential to understand the requirements. Delivery times may be longer, as there are fewer manufacturers of seamless pipes than welded pipes (lower entry barriers exist for welded pipes vs. seamless pipes) seamless pipes may have an inconsistent wall thickness across their length, indeed the general tolerance is 12.5%; erw pipe pros and cons. Efw pipe is a variety of welded pipe made by a method referred to as electric fusion welded. this process is such that first a flat plate or steel coils are shaped into pipes which are rolled and welded along the joints using high electric frequencies. efw pipes are known to be very strong and are also very durable to a wide range of conditions.

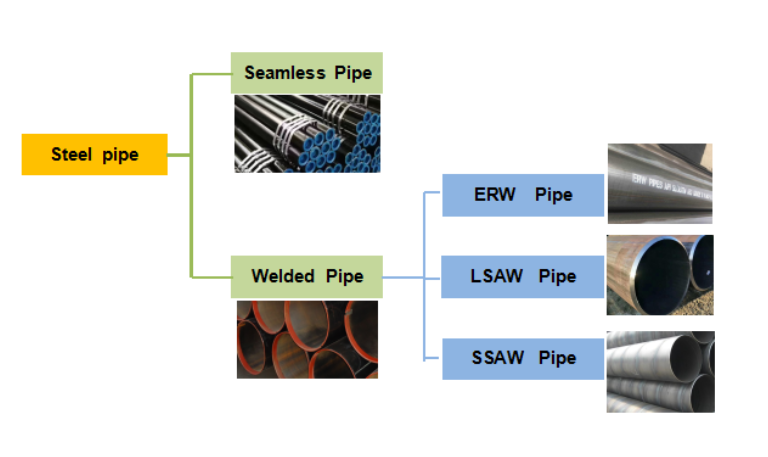

Types Of Pipes Erw Hfw Seamless Efw Spiral And Saw Pipe Delivery times may be longer, as there are fewer manufacturers of seamless pipes than welded pipes (lower entry barriers exist for welded pipes vs. seamless pipes) seamless pipes may have an inconsistent wall thickness across their length, indeed the general tolerance is 12.5%; erw pipe pros and cons. Efw pipe is a variety of welded pipe made by a method referred to as electric fusion welded. this process is such that first a flat plate or steel coils are shaped into pipes which are rolled and welded along the joints using high electric frequencies. efw pipes are known to be very strong and are also very durable to a wide range of conditions. Erw and seamless steel piping exist as alternatives today largely due to historical perceptions. generally, welded pipe was considered inherently weaker because it included a weld seam. seamless pipe lacked this perceived structural flaw and was considered safer. while it’s true that welded pipe does include a seam that makes it theoretically. Erw pipes are created by electric resistance welding, which involves fusing the edges of a flat strip to form a pipe with a visible weld seam. in contrast, efw pipes are made through the electric fusion welding of a molten material, resulting in a seamless pipe without any weld seam.

7 Differences Between Seamless Pipe And Seam Welded Pipe 7 Differences Erw and seamless steel piping exist as alternatives today largely due to historical perceptions. generally, welded pipe was considered inherently weaker because it included a weld seam. seamless pipe lacked this perceived structural flaw and was considered safer. while it’s true that welded pipe does include a seam that makes it theoretically. Erw pipes are created by electric resistance welding, which involves fusing the edges of a flat strip to form a pipe with a visible weld seam. in contrast, efw pipes are made through the electric fusion welding of a molten material, resulting in a seamless pipe without any weld seam.

Comments are closed.