Ductile Iron Pipe Dimensions Chart A Visual Reference Of Charts

Ductile Iron Pipe Dimensions What Is Piping Ductile iron pipe design nsf ® certifie d to ansi nsf 61 86 p 2 6. di p. p ip e 2013 editi o n u.s. pipe and foundry co. ductile iron pipe design bro 001 revised 10.13 table of contents ductile iron pipe 3 laying conditions 5 design method and examples of selection method 6 pressure class 10 thickness class 11 earth load plus truck load 12. Selection tale for ductile iron pipe nsf ® certified to ans i ns 61 866.dip.pipe u.s. pipe and foundry company 866.dip.pipe uspipe p 3 u.s. pipe usp 0550 pressure classthickness class risd 01.1 size inches pressure class psi nominal thickness inches od* inches tyton® joint tr flex® joint hp lok® joint 4 350 0.25 4.80 10.9 11.7.

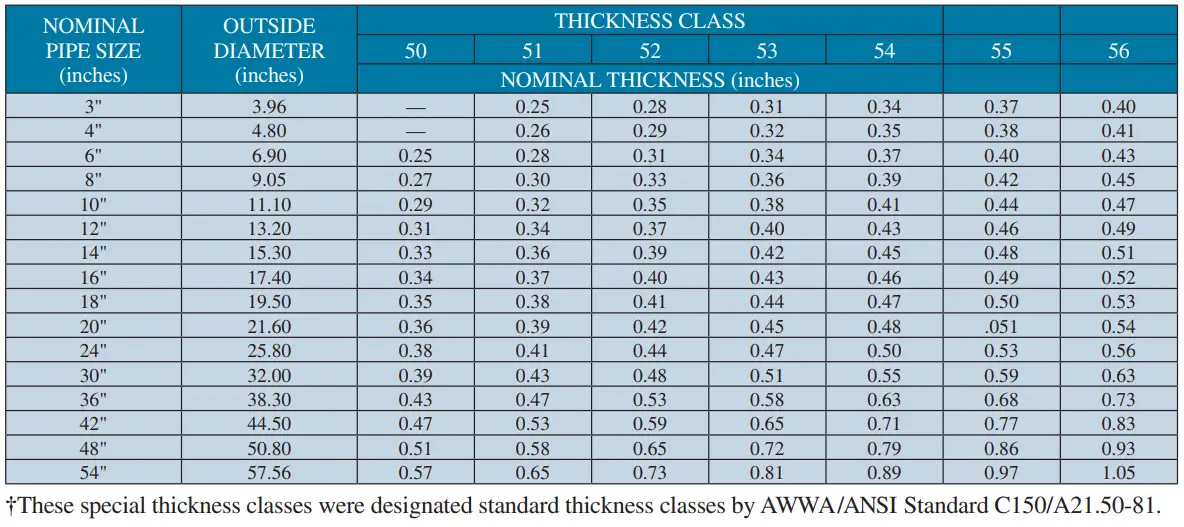

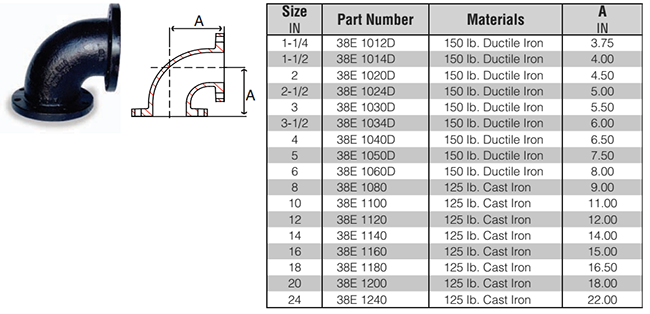

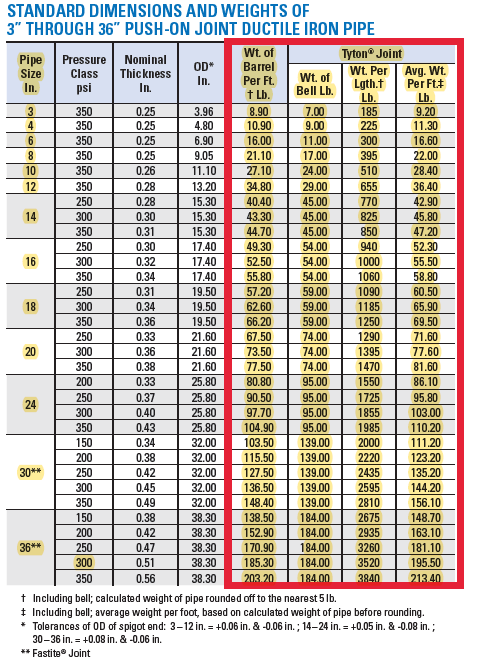

Ductile Iron Pipe Dimensions Chart A Visual Reference Of Charts Ductile iron pipe sizes and dimensions. dimensions of ductile iron pipe special pressure classes (customary u.s. units) iron pipe per. ansi awwa c150 a21.50 and ansi awwa c151 a21.51. (multiply lbf in 2 by 6.895 to obtain kpa.) a formerly designated “standard thickness classes.”. these special pressure classes are as shown in awwa c150 and. Pipe size pipe class pipe wall unl scl dcl inside diameters pipe size pipe class pipe wall inside diameters unl scl dcl 20 250 0.33 20.94 20.75 20.57 300 0.36 20.88 20.69 20.51 50 0.36 20.88 20.69 20.51 350 0.38 20.84 20.65 20.47 51 0.39 20.82 20.63 20.45 52 0.42 20.76 20.57 20.39 53 0.45 20.70 20.51 20.33 od 21.60 54 0.48 20.64 20.45 20.27. Restrained joint pipe and fittings 90° and 45° bends. 22 1⁄2° and 11 1⁄4° bends 60°, 30° and 5 5 8° bends all socket tee double socket body tees with flanged branch double socket taper connecting pieces products for water, wastewater, and fire protection. 26. 27. Of push on joint ductile iron pipe page 110 18. standard dimensions and weights of mechanical joint ductile iron pipe page 114 19. pipe thicknesses required for different tap sizes per ansi asme b1.20.1 page 116 20. pipe thicknesses required for different tap sizes per awwa c800 page 120 21. nomograph for pipe size, head loss, and discharge for.

Ductile Iron Pipe Dimensions Chart Piping Guide Joining Ductile Or Restrained joint pipe and fittings 90° and 45° bends. 22 1⁄2° and 11 1⁄4° bends 60°, 30° and 5 5 8° bends all socket tee double socket body tees with flanged branch double socket taper connecting pieces products for water, wastewater, and fire protection. 26. 27. Of push on joint ductile iron pipe page 110 18. standard dimensions and weights of mechanical joint ductile iron pipe page 114 19. pipe thicknesses required for different tap sizes per ansi asme b1.20.1 page 116 20. pipe thicknesses required for different tap sizes per awwa c800 page 120 21. nomograph for pipe size, head loss, and discharge for. Deflection check. maximum allowable ring deflection for cement mortar lined ductile iron pipe is 3 percent of the outside diameter (5 percent for flexible linings). tests have shown that 3 percent deflection will provide a safety factor of at least 2.0 with regard to failure of the cement mortar lining. This size and dimension chart is intended for reference purposes. it should not be used in place of the advice from a licensed professional engineer. pipe weights are calculated in accordance with ppi tr 7. average inside diameter is calculated using dips od and minimum wall plus 6% for use in estimating fluid flows. actual id will vary.

Comments are closed.