Dmaic And Other Six Sigma Tools To Drive Continuous Improvement

Dmaic And Other Six Sigma Tools To Drive Continuous Improvement The lean six sigma methodology. as previously mentioned, lean six sigma is a structured and systematic approach that combines lean and six sigma principles to achieve operational excellence and continuous improvement in organizations. it provides a clear and directed path for problem solving and process improvement, addressing waste elimination. Six sigma tools are defined as the problem solving tools used to support six sigma and other process improvement efforts. the six sigma expert uses qualitative and quantitative techniques to drive process improvement. although the tools themselves are not unique, the way they are applied and integrated as part of a system is.

Six Sigma Dmaic Methodology Dmaic is a continuous improvement methodology consisting of 5 phases: define, measure, analyze, improve, and control, and is included within the tools of the six sigma philosophy. each stage is designed to follow a logical sequence in the search for continuous improvement in a given process. if you want to learn more about standardization, six. Dmaic is an acronym that stands for define, measure, analyze, improve, and control. it is a systematic and data driven methodology used in six sigma and other process improvement initiatives. dmaic provides a structured framework for organizations to identify, measure, analyze, improve, and control existing processes to enhance efficiency. Dmaic‘s lineage traces back to the 1930s with walter shewhart’s development of the pdsa (plan do study act) cycle, which laid the groundwork for systematic process improvement. this foundational concept was further refined through the six sigma approach, spearheaded by motorola in the 1980s and later adopted by general electric. dmaic. The five stages of the dmaic improvement cycle. the dmaic framework includes five stages in the existing process improvement cycle. they are: define. measure. analyze. improve. control. these five steps provide a systematic framework for moving six sigma projects from initial stages all the way to completion.

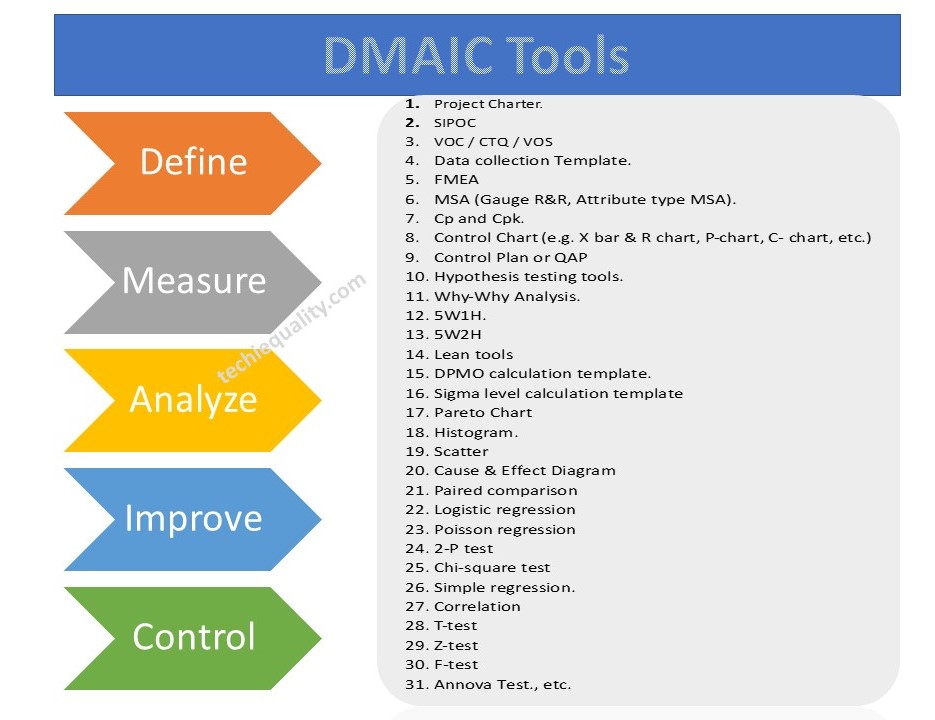

Dmaic Tools Dmaic Template 30 Tools 6 Sigma Methodology Dmaic‘s lineage traces back to the 1930s with walter shewhart’s development of the pdsa (plan do study act) cycle, which laid the groundwork for systematic process improvement. this foundational concept was further refined through the six sigma approach, spearheaded by motorola in the 1980s and later adopted by general electric. dmaic. The five stages of the dmaic improvement cycle. the dmaic framework includes five stages in the existing process improvement cycle. they are: define. measure. analyze. improve. control. these five steps provide a systematic framework for moving six sigma projects from initial stages all the way to completion. The level of tools and rigor you apply is based on your judgement on rigor vs stakes vs urgency. dmaic. dmaic is a data driven quality approach used in continuous improvement. while it is a core part of six sigma, it can also be implemented alone. dmaic is an acronym for five stages:. Dmaic is an acronym that stands for define, measure, analyze, improve, and control. it represents the five phases that make up the process: define the problem, improvement activity, opportunity for improvement, the project goals, and customer (internal and external) requirements. project charter to define the focus, scope, direction, and.

Comments are closed.