Distribution Board Wiring And Load Schedule Details Load Schedule

Distribution Board Wiring And Load Schedule Details Load Schedule The basic steps for creating a load schedule are: step 1: collect a list of the expected electrical loads in the facility. step 2: for each load, collect the electrical parameters, e.g. nominal absorbed ratings, power factor, efficiency, etc. step 3: classify each of the loads in terms of switchboard location, load duty and load criticality. Switchboard panel schedule. it is a panel used with switchboards. it shows details of the panel boards connected to a switchboard. what do process and non process loads mean? when supplying electrical loads during power installation, you will create two types of electrical loads that are controlled by the load schedule.

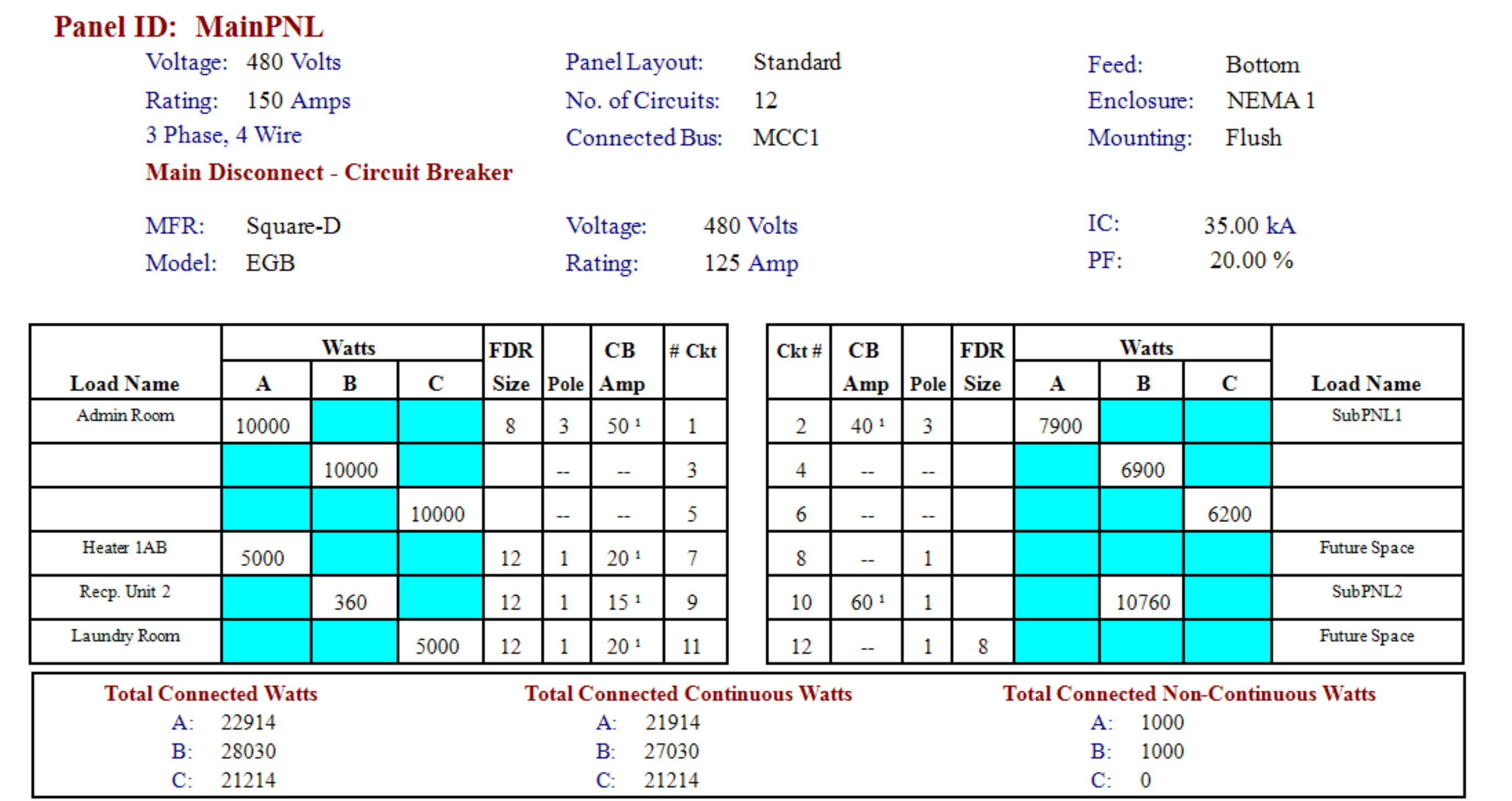

Panel Schedule Software Load Schedule Design Distribution Board Nec 430 22 = the size of the wire supplying motorized load shall not be less than 125% of the rated full load current of the motor. 3. nec 430 52 = the size of the branch circuit protection for motor loads shall not be greater than 250% of motor full load current for cb and 300% for non time delay fuses on full voltage starting. Calculate the right size of load center or main electric panel for an 1500 ft2 (square foot) or 139.35 m2 (square meters) home floor plan having the following load points: air conditioner: 240v × 25a = 6000 va = 6 kva. electric range: 240v × 35a = 9600 va = 8.4 kva. electric heater: 240v × 30a = 7200 va = 7.2 kva. An electrical panel schedule will tell us what circuits, the breaker or fuse size, but not tell us the full picture. so make sure to read your equipment schedule, too, before pulling wire! also, in addition to this equipment schedule, we also have something called a spec sheet (or data sheet), which will tell us even more details about that. Developed for electrical designers and engineers, the power panel schedule software combines a graphical user interface and the intelligence of etap to easily, layout, design, calculate, and analyze low and medium voltage panel load schedules and distribution panel boards. coupled with exclusive features and advanced capabilities, power panel.

How To Wire 1 Phase 3 Phase Split Load Distribution Board An electrical panel schedule will tell us what circuits, the breaker or fuse size, but not tell us the full picture. so make sure to read your equipment schedule, too, before pulling wire! also, in addition to this equipment schedule, we also have something called a spec sheet (or data sheet), which will tell us even more details about that. Developed for electrical designers and engineers, the power panel schedule software combines a graphical user interface and the intelligence of etap to easily, layout, design, calculate, and analyze low and medium voltage panel load schedules and distribution panel boards. coupled with exclusive features and advanced capabilities, power panel. The three phase distribution board wiring diagram shows how the current flows between the various components in the three phase distribution board. it also includes details of the ratings of the components, the type of cable used, the wire size and amperage rating, and other important information. this information can be used to determine the. The phase and neutral supply lines (230v ac 50hz 60hz) are fed to the db through the service drop running from the utility pole. it is then connected to the energy meter through a fuse. the phase and neutral lines from the energy meter are connected to the main isolator. the isolator is used to open and close the lines manually, which is the.

Comments are closed.