Discovering Api 6d Valves Best Practices

Discovering Api 6d Valves Best Practices Youtube Learn about the api 6d standard and the different types of valves and their associated features. plus, get the latest information related to common pitfalls. By following these installation, operation, and maintenance best practices, api 6d gate valves can deliver reliable performance and contribute to the efficiency and safety of fluid control systems. in the next section, we will explore the challenges and limitations that engineers and operators might encounter when working with these valves.

Api 6d Api 6a Valves Cti Controltech Industrial Combustion And Iso 17292 and api 6d stand at the forefront of these benchmarks, guiding the production of metal ball valves for the petroleum, petrochemical, and allied industries with unwavering precision and quality control. this guide aims to demystify the nuanced distinctions and overlapping territories between iso 17292 vs api 6d, offering a clear. The api 6d specification is an adoption of iso 14313: 1999, petroleum and natural gas industries pipeline transportation systems pipeline valves. this international standard specifies requirements and gives recommendations for the design, manufacturing, testing and documentation of ball, check, gate and plug valves for application in pipeline systems. 6d is the primary specification used for. Api 608 is a meticulously crafted standard that delineates the design, manufacturing, and testing criteria for metal ball valves used in the oil and gas industry, particularly those intended for use in process services where flammable or hazardous materials are handled. this standard encompasses a broad range of valve sizes, pressure classes. The api 6d is the most preferred specification majorly for the pipeline valves. it is the main standard according to the iso 14313 that defines the condition of valves and provides suggestions for the design, manufacture, inspecting, and documentation of different valves including check, ball, plug, and gate valves in piping systems.

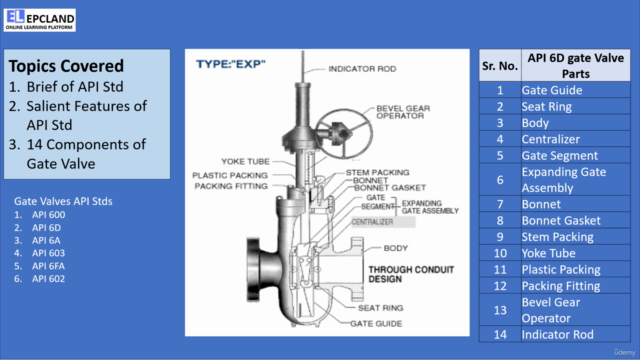

14 Components Of Api 6d Valve Free Course Api 608 is a meticulously crafted standard that delineates the design, manufacturing, and testing criteria for metal ball valves used in the oil and gas industry, particularly those intended for use in process services where flammable or hazardous materials are handled. this standard encompasses a broad range of valve sizes, pressure classes. The api 6d is the most preferred specification majorly for the pipeline valves. it is the main standard according to the iso 14313 that defines the condition of valves and provides suggestions for the design, manufacture, inspecting, and documentation of different valves including check, ball, plug, and gate valves in piping systems. There are three types of tests required under api 6d: stem backseat test. hydrostatic shell test. hydrostatic seat test. for valves up to 16” x 300 lbs, we can perform these tests using our barbee tf 100 daq test stand. we have tested up to 24” 900# in the shop, and we can test larger valves with bolt on flanges into the valve. Api 6d valves – types, vs. api 598. api 6d is the american petroleum institute’s specification for pipeline and pipeline valves in the petroleum and natural gas industries. it contains requirements for the design, manufacture, assembly, documentation, and testing of ball, gate, plug, and check valves for pressure ratings up to asme class 2500.

Api 6d Valves Bonney Forge Pdf Pdf Valve Nondestructive Testing There are three types of tests required under api 6d: stem backseat test. hydrostatic shell test. hydrostatic seat test. for valves up to 16” x 300 lbs, we can perform these tests using our barbee tf 100 daq test stand. we have tested up to 24” 900# in the shop, and we can test larger valves with bolt on flanges into the valve. Api 6d valves – types, vs. api 598. api 6d is the american petroleum institute’s specification for pipeline and pipeline valves in the petroleum and natural gas industries. it contains requirements for the design, manufacture, assembly, documentation, and testing of ball, gate, plug, and check valves for pressure ratings up to asme class 2500.

Api 6d Valves And Api 6d Globe Butterfly Valve Suppliers In Uae

Comments are closed.