Different Types Of Flanges For Piping Explained

Piping Flanges Types Of Flanges In Piping Systems Types of flanges. in this article, we review the 13 types of flanges for pipelines and piping systems (asme b16.5), divided into “standard” and “non standard” (or less common) types. large flange sizes, not examined here, are ruled by the asme b16.47 series a b specification. classification of asme flanges b16.5:b16.47 & special flanges. Many different flange standards are found worldwide to allow easy functionality and interchangeability. common standards include asa asme (usa), pn din (european), bs10 (british australian), and jis ks (japanese korean). flanges come in many different shapes and sizes and are used in a wide range of industries around the world.

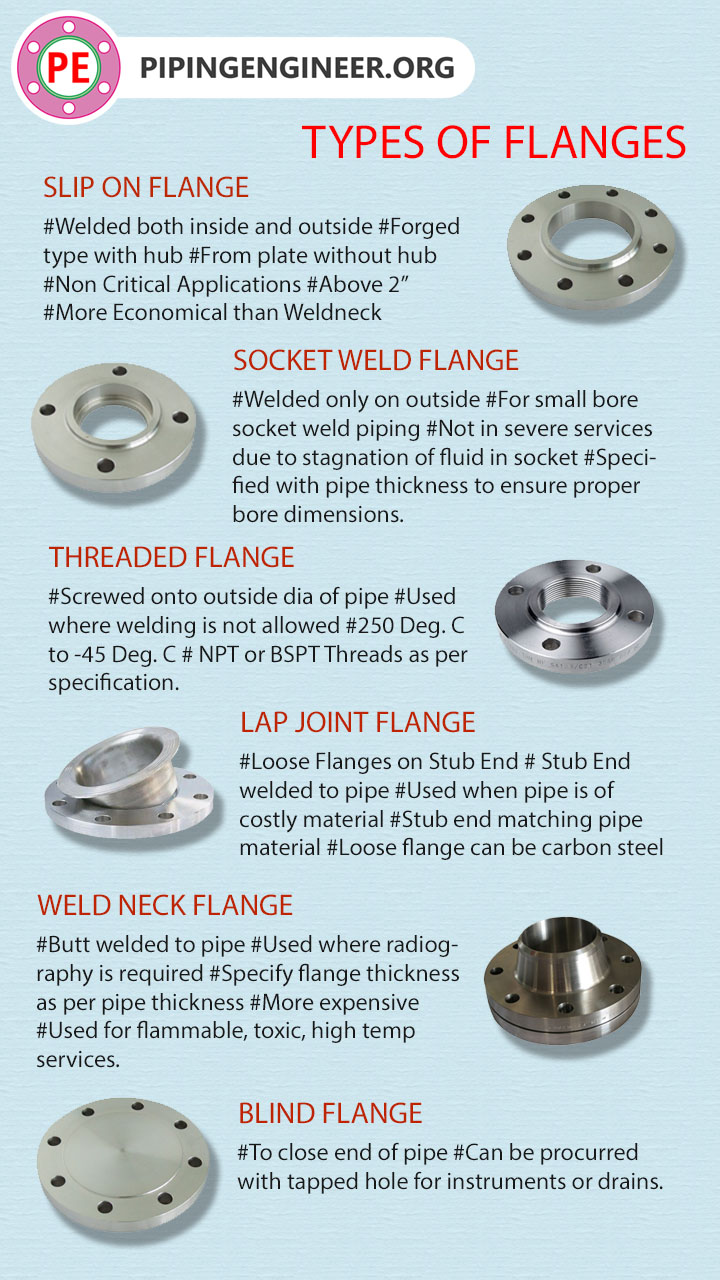

Piping Flanges Types Of Flanges In Piping Systems 56 Off Threaded or screwed flange. threaded flanges are joined to pipes by screwing the pipe and are used on piping systems that prohibit direct welding on the pipe. usually, threaded flanges are used for galvanized piping. industrial threaded flanges are made in sizes up to 4 inches with various pressure ratings. Socket weld flange. socket weld flange refers to a type of flange where the end of a pipe is inserted into a step inside the flange, and then welded on the inside and outside of the pipe end. there are two types, one with a neck and one without. the socket weld flange with a neck has good rigidity, small welding deformation, and better sealing. Flange design is only the start when considering the ideal flange for your piping system. face types are another characteristic that will have a major impact on the final performance and service life of your flanges. facing types determine both the gaskets needed to install the flange and characteristics related to the seal created. Pipe flanges have flush or flat surfaces that are perpendicular to the pipe to which they attach. two of these surfaces are mechanically joined via bolts, collars, adhesives or welds. this video depicts the layout of a flange connection using bolts. typically, flanges are attached to pipes via welding, brazing, or threading.

Different Types Of Flanges For Piping Explained Flange design is only the start when considering the ideal flange for your piping system. face types are another characteristic that will have a major impact on the final performance and service life of your flanges. facing types determine both the gaskets needed to install the flange and characteristics related to the seal created. Pipe flanges have flush or flat surfaces that are perpendicular to the pipe to which they attach. two of these surfaces are mechanically joined via bolts, collars, adhesives or welds. this video depicts the layout of a flange connection using bolts. typically, flanges are attached to pipes via welding, brazing, or threading. Lap joint flanges consist of a stub end and a lap joint ring. the stub end is welded to the pipe, while the lap joint ring fits over the stub end. this design provides flexibility in adjusting the pipe’s length and simplifies the system’s installation and maintenance. blind flanges are used to terminate or end a piping system or vessel. 1. welding neck flange. the welding neck flanges consist of a long tapered hub. this tapered hub goes inside the pipe, whereas the flange’s other end is joined with the pipe or pipe fittings using butt welding. welding neck type of flange has applications in high temperature and pressure applications. 2.

5 Different Types Of Piping Flanges Explained Lap joint flanges consist of a stub end and a lap joint ring. the stub end is welded to the pipe, while the lap joint ring fits over the stub end. this design provides flexibility in adjusting the pipe’s length and simplifies the system’s installation and maintenance. blind flanges are used to terminate or end a piping system or vessel. 1. welding neck flange. the welding neck flanges consist of a long tapered hub. this tapered hub goes inside the pipe, whereas the flange’s other end is joined with the pipe or pipe fittings using butt welding. welding neck type of flange has applications in high temperature and pressure applications. 2.

Different Types Of Flanges For Piping Explained

Types Of Flanges The Piping Engineering World

Comments are closed.