Differences Between Turning And Milling

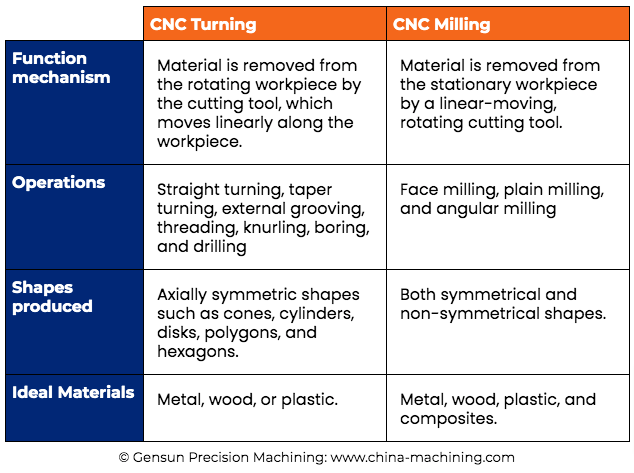

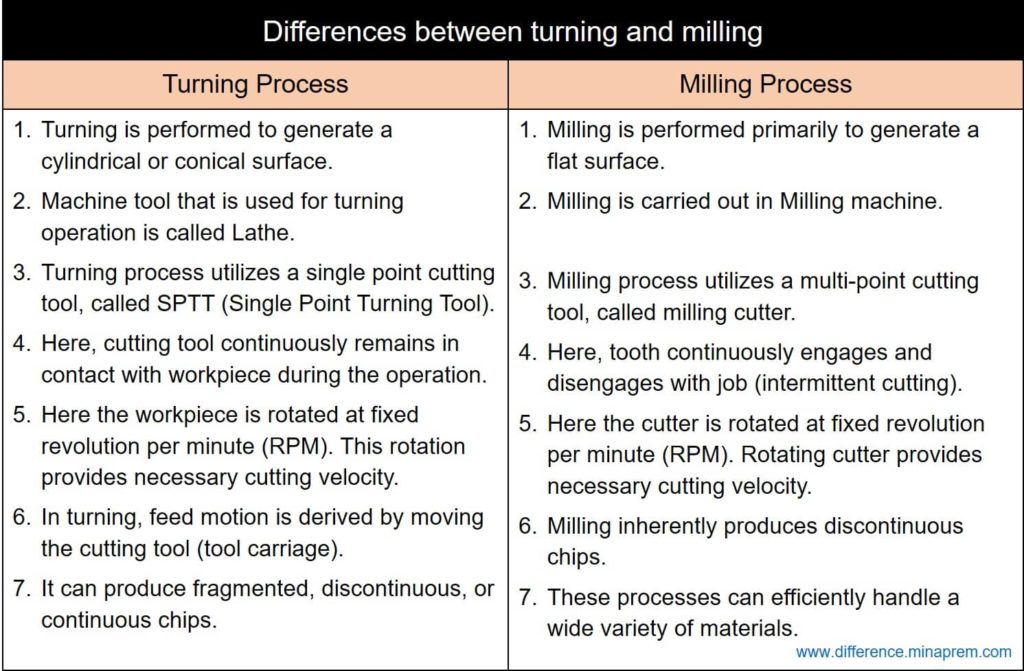

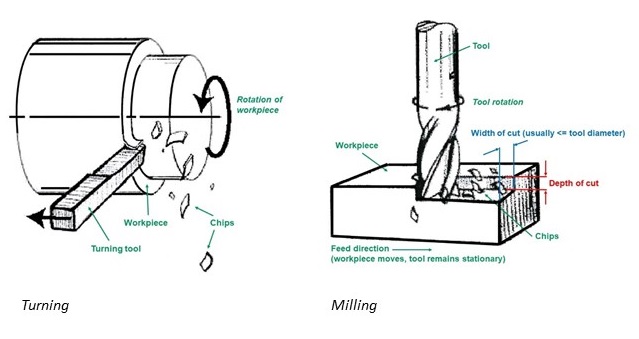

Cnc Turning And Milling Do You Understand The Difference Turning is generally faster for creating symmetrical, round parts, while milling offers greater flexibility for producing complex shapes and features. the choice between turning and milling depends on factors such as the desired part geometry, material properties, production volume, and required surface finish. The main difference between these two machining processes lies in their use of rotation. in turning operations, the workpiece rotates. in milling operations, the cutting tool rotates. there are two main classifications of milling operations: face and peripheral. face milling is characterized by a cutting action at or near the corners of the.

Difference Between Turning And Milling Key differences between turning and milling. when it comes to precision machining, turning and milling are two commonly used techniques. understanding the key differences between these processes is essential for manufacturers and engineers. let’s explore the distinct characteristics of turning and milling operations. Turning is generally faster and more efficient for producing round parts, while milling offers greater versatility for creating a wide range of shapes and features. the choice between turning and milling depends on factors such as the desired part geometry, material, production volume, and required precision. Most cylindrical parts with features will be turned. pioneer services offer cnc swiss and cnc turning center contract precision machining services. parts range from 0.145” (5 mm) to 3.25” (82.55 mm) in diameter. our cnc swiss machines can run parts up to 1.5” (38mm) and our cnc turning centers can handle parts to the full 3.25” (82.55mm). There are two basic types of vertical centers: turret and bed. turret vertical mills keep the spindle stationary while the table moves along linear axes to direct the cutting. bed vertical mills allow the spindle to move along the y axis while the table moves along the x axis. horizontal milling centers have the spindle oriented horizontally.

Cnc Turning And Milling What S The Difference Aldermans Most cylindrical parts with features will be turned. pioneer services offer cnc swiss and cnc turning center contract precision machining services. parts range from 0.145” (5 mm) to 3.25” (82.55 mm) in diameter. our cnc swiss machines can run parts up to 1.5” (38mm) and our cnc turning centers can handle parts to the full 3.25” (82.55mm). There are two basic types of vertical centers: turret and bed. turret vertical mills keep the spindle stationary while the table moves along linear axes to direct the cutting. bed vertical mills allow the spindle to move along the y axis while the table moves along the x axis. horizontal milling centers have the spindle oriented horizontally. Turning: the art of symmetry. turning, in contrast to milling, is all about symmetry and rotation. here, your component is fastened to a turret and spun while a cutting tool shapes it. it's similar to pottery; as the piece spins, the tool sculpts it into a perfect circle. this method is ideal for creating cylindrical parts. Key differences. operation: turning involves the rotation of the workpiece, while milling involves the rotation of the cutting tool. tooling: turning primarily uses single point cutting tools, while milling employs multi point cutting tools, such as end mills and face mills. workpiece geometry: turning is best suited for cylindrical parts.

Differences Between Turning And Milling Youtube Turning: the art of symmetry. turning, in contrast to milling, is all about symmetry and rotation. here, your component is fastened to a turret and spun while a cutting tool shapes it. it's similar to pottery; as the piece spins, the tool sculpts it into a perfect circle. this method is ideal for creating cylindrical parts. Key differences. operation: turning involves the rotation of the workpiece, while milling involves the rotation of the cutting tool. tooling: turning primarily uses single point cutting tools, while milling employs multi point cutting tools, such as end mills and face mills. workpiece geometry: turning is best suited for cylindrical parts.

Cnc Turning And Milling Understanding Their Differences Wayken

Comments are closed.