Deposition Welding Trumpf

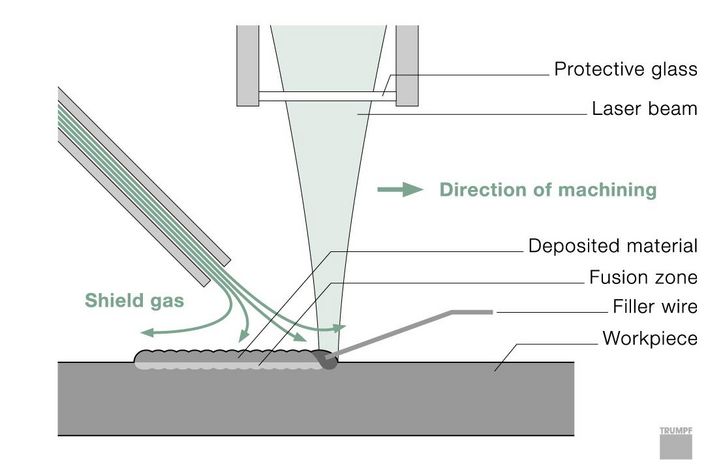

Trumpf Laser Metal Deposition Welding Youtube Deposition welding is a generating process that is applied for surface finishing as well as repairing or modifying existing components. depending on the task at hand, either manual or automated laser deposition welding is used. manual laser deposition welding. in the case of manual deposition welding, the welder guides the filler material "by. In conventional laser metal deposition, the laser beam heats up the workpiece locally, creating a weld pool. fine metal powder is sprayed directly into the weld pool from a nozzle in the processing optics. this fine metal powder melts there and combines with the base material. a layer of approx. 0.2 to 1 millimeter thickness remains.

Deposition Welding Trumpf Trumpf laser systems enable high speed laser deposition (hs lmd). here, large components can be coated at over 250 square centimeters a minute. along with netvision, our partner for scanning software, we demonstrate the process chain for scanning components, tool path planning and subsequent laser metal deposition welding for component repair. Laser metal deposition (lmd) welding is a surface treatment process that adds a layer or layers of material onto a workpiece. the laser melts a pool of metal. In this process, the laser generates a weld pool on the component surface. a metal filler material is then continuously added and melted in this pool, beads. The 3d laser machine trulaser cell 3000 from trumpf can be used for two and three dimensional cutting and welding, as well as for additive manufacturing or laser metal deposition (lmd). high speed laser metal deposition for rotationally symmetrical components is possible as well.

Ehla Trumpf Is Ready For Extreme High Speed Laser Deposition Welding In this process, the laser generates a weld pool on the component surface. a metal filler material is then continuously added and melted in this pool, beads. The 3d laser machine trulaser cell 3000 from trumpf can be used for two and three dimensional cutting and welding, as well as for additive manufacturing or laser metal deposition (lmd). high speed laser metal deposition for rotationally symmetrical components is possible as well. Laser metal deposition (lmd) is a generative manufacturing method for metals and explained by trumpf in this video using their latest technology. trumpf explains that people also talk about ‘direct metal deposition’ (dmd) or ‘direct energy deposition’ (ded). the laser creates a weld pool on the component surface. metal powder is. New ehla method capable of extremely high laser deposition welding speeds enables trumpf laser systems to coat large area components at a rate of over 250 square centimeters per minute. the laser system manufacturer trumpf is putting the new ehla method into series production (in german, ehla stands for extreme high speed laser deposition.

Laser Metal Deposition Machine Trumpf Trulaser Cell 7040 Twi Laser metal deposition (lmd) is a generative manufacturing method for metals and explained by trumpf in this video using their latest technology. trumpf explains that people also talk about ‘direct metal deposition’ (dmd) or ‘direct energy deposition’ (ded). the laser creates a weld pool on the component surface. metal powder is. New ehla method capable of extremely high laser deposition welding speeds enables trumpf laser systems to coat large area components at a rate of over 250 square centimeters per minute. the laser system manufacturer trumpf is putting the new ehla method into series production (in german, ehla stands for extreme high speed laser deposition.

Deposition Welding Trumpf

Ehla Trumpf Is Ready For Extreme High Speed Laser Deposition Welding

Comments are closed.