Crude Oil How Oil Refining Works Howstuffworks

Crude Oil How Oil Refining Works Howstuffworks On average, crude oils are made of the following elements or compounds: carbon 84%. hydrogen 14%. sulfur 1 to 3% (hydrogen sulfide, sulfides, disulfides, elemental sulfur) nitrogen less than 1% (basic compounds with amine groups) oxygen less than 1% (found in organic compounds such as carbon dioxide, phenols, ketones, carboxylic acids). How oil refining works. oil fields image gallery refineries turn crude oil into products such as gasoline and plastics. see more pictures of oil fields and refining. in movies and television shows giant, oklahoma crude, armageddon, beverly hillbillies we have seen images of thick, black crude oil gushing out of the ground or a.

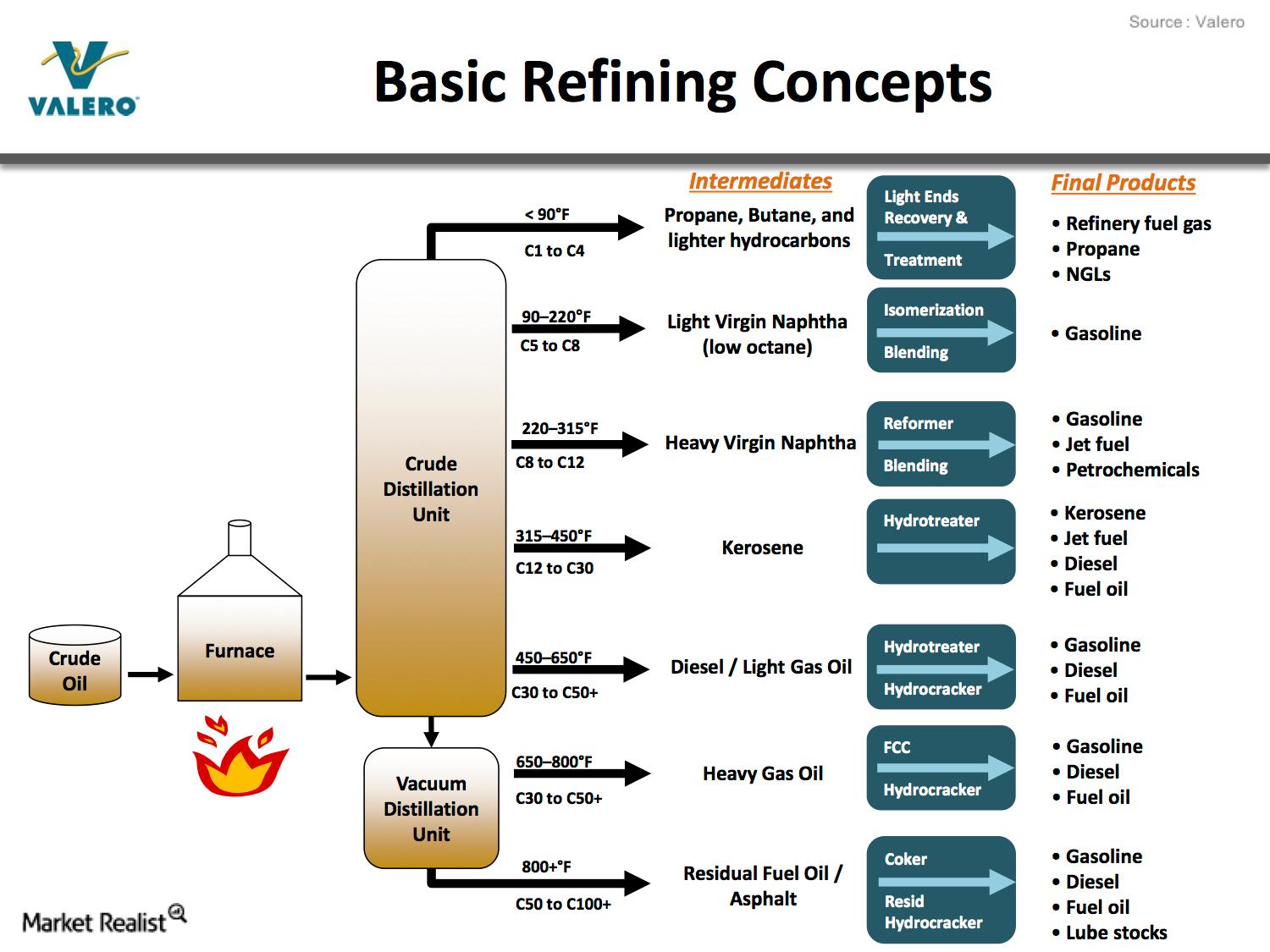

Crude Unit Flow Diagram From crude oil. the oil refining process starts with a fractional distillation column. the problem with crude oil is that it contains hundreds of different types of hydrocarbons all mixed together. you have to separate the different types of hydrocarbons to have anything useful. fortunately there is an easy way to separate things, and this is. Crude oil refineries employ some of the united states’ top scientists, engineers, and safety professionals to ensure that products are produced efficiently and safely. us refineries process about 17 million barrels of crude oil a day. refinery configurations vary, but us refineries are undeniably some of the world’s most sophisticated. Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products. petroleum refineries are complex and expensive industrial facilities. all refineries have three basic steps: separation; conversion; treatment; separation. modern separation involves piping crude oil through hot furnaces. 3. refining. the crude is heated by a furnace and is sent to a distillation tower, where it is separated by boiling point. then the material is converted by heating, pressure or a catalyst into finished products including fuels like gasoline and diesel, and specialty products like asphalt and solvents. 4.

What Is The Process Of Crude Oil Refining Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products. petroleum refineries are complex and expensive industrial facilities. all refineries have three basic steps: separation; conversion; treatment; separation. modern separation involves piping crude oil through hot furnaces. 3. refining. the crude is heated by a furnace and is sent to a distillation tower, where it is separated by boiling point. then the material is converted by heating, pressure or a catalyst into finished products including fuels like gasoline and diesel, and specialty products like asphalt and solvents. 4. In this process, crude oil is heated and fed into a distillation column. a schematic of the distillation column is shown in figure 2.2 f i g u r e 2.2. as the temperature of the crude oil in the distillation column rises, the crude oil separates itself into different components, called “fractions.”. the fractions are then captured separately. The total volume of products that refineries produce (output) is greater than the volume of crude oil that refineries process (input) because most of the products they make have a lower density than the crude oil they process. this increase in volume is called processing gain. the average processing gain at u.s. refineries was about 6.3% in 2023.

How Oil Refining Works Geología Ciencia Y Electromecanica In this process, crude oil is heated and fed into a distillation column. a schematic of the distillation column is shown in figure 2.2 f i g u r e 2.2. as the temperature of the crude oil in the distillation column rises, the crude oil separates itself into different components, called “fractions.”. the fractions are then captured separately. The total volume of products that refineries produce (output) is greater than the volume of crude oil that refineries process (input) because most of the products they make have a lower density than the crude oil they process. this increase in volume is called processing gain. the average processing gain at u.s. refineries was about 6.3% in 2023.

Comments are closed.