Cooling And Chilled Water Systems Training Convergence

Cooling And Chilled Water Systems Training Convergence Available in both virtual and in person, instructor led formats, this chilled water systems seminar will teach you how to keep your system running efficiently, whether it keeps people or equipment cool. 2 days $1,495.00 gary xavier, john jacobs. 1.6 pd points. 16 pd hours. Call (855) 712 7353 for more info on schedule and pricing! 100% of ntt's offering can be brought to your facility request on site training. skilled workers. stronger companies. ntt training. give your employees the hands on chillers operation & maintenance skills training they need from the experts at ntt training. sign up for a course now!.

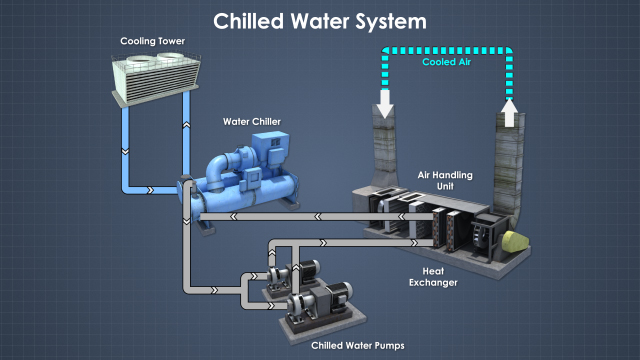

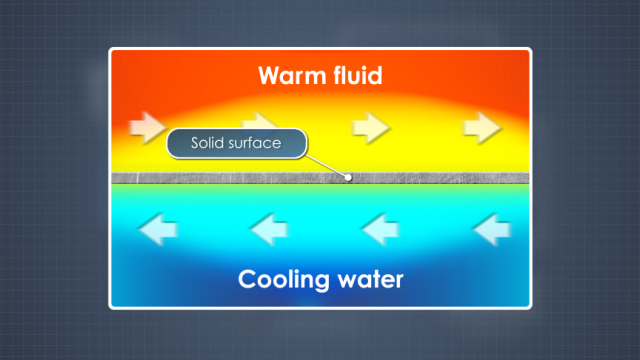

Cooling And Chilled Water Systems Training Convergence Chilled water system is a type of air conditioning system that uses chilled water (low temperature water) for cooling and dehumidification. it is a combination of multiple components that serve different purposes such as water cooling, water circulation, air cooling, dehumidifying of air and heat rejection. unlike conventional air conditioning. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. An approach to selecting chillers using life cycle cost techniques. general factors that should be considered when designing and installing a chw plant building automation system (bas) and suggested control sequences. elements of the commissioning (cx) process that are key to ensuring that chiller plants meet their design intent. Chillers use the refrigeration cycle to remove heat from water. a chilled water system’s refrigeration cycle works by removing heat from chilled water in the evaporator of the chiller. the compressor is what drives the entire process. it also uses the most energy in a chilled water system. in the condenser of the chiller, the heat is.

Cooling And Chilled Water Systems Training Convergence An approach to selecting chillers using life cycle cost techniques. general factors that should be considered when designing and installing a chw plant building automation system (bas) and suggested control sequences. elements of the commissioning (cx) process that are key to ensuring that chiller plants meet their design intent. Chillers use the refrigeration cycle to remove heat from water. a chilled water system’s refrigeration cycle works by removing heat from chilled water in the evaporator of the chiller. the compressor is what drives the entire process. it also uses the most energy in a chilled water system. in the condenser of the chiller, the heat is. This course provides a description of common chilled water system types from the most basic constant flow to all variable flow systems along with advantages and limitations. for purposes of discussion, chilled water pumping systems are divided into three categories. 1. constant volume chilled water systems 2. primary secondary chilled water. Sure setpoint or chilled water setpoint.select chiller for 2 to 4°f lower supply chilled water temperature than the cooling coils, to allow supply temperature reduction compensation for. irside low Δt or increased system load.install pressure independent cooling coil control valves to preserve system.

Cooling And Chilled Water Systems Training Convergence This course provides a description of common chilled water system types from the most basic constant flow to all variable flow systems along with advantages and limitations. for purposes of discussion, chilled water pumping systems are divided into three categories. 1. constant volume chilled water systems 2. primary secondary chilled water. Sure setpoint or chilled water setpoint.select chiller for 2 to 4°f lower supply chilled water temperature than the cooling coils, to allow supply temperature reduction compensation for. irside low Δt or increased system load.install pressure independent cooling coil control valves to preserve system.

Guide To Chilled Water Systems And Improving Efficiency Endocool

Comments are closed.