Comparing Turning Drilling Milling And Threading Steelmor

Comparing Turning Drilling Milling And Threading Steelmor Comparing turning, drilling, milling, and threading in metal machining under the title of metal machining, there are several different techniques. machining is a versatile manufacturing process, so it is a good idea to become familiar with the various options available to you. Steelmor industries, your stainless steel experts comparing turning, drilling, milling, and threading in metal machining comparing turning, drilling, milling, and threading in metal machining.

Manufacturing Processes I At steelmor, we have a team of qualified and experience machinists who are committed to supplying you with cost effective and quality stainless steel products on time, all the time. why not call and chat to us today to see how we can help you with your machining requirements. steelmor have a selection of steel machining tools. Thread milling primer. thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. it involves cutting a thread using a unique milling cutter that moves in a helical path. thread milling can be a complex and challenging application for many, as it requires relatively complex programming and. As a cutting process, drilling is considered to be one of the more cost effective solutions for metal machining. milling. milling is done using multi point rotary cutters. these cutters remove material from a piece. face milling and peripheral milling are your two main choices here: face milling cuts flat surfaces, either horizontally or vertically. Drilling produces a round hole in a workpiece. a tapping or drill press machine performs drilling operations. however, drilling can also be handled with a milling machine. when machining a workpiece, chips are the waste material produced during the machining process. the way the drill bit is shaped enables chips to fall away from the workpiece.

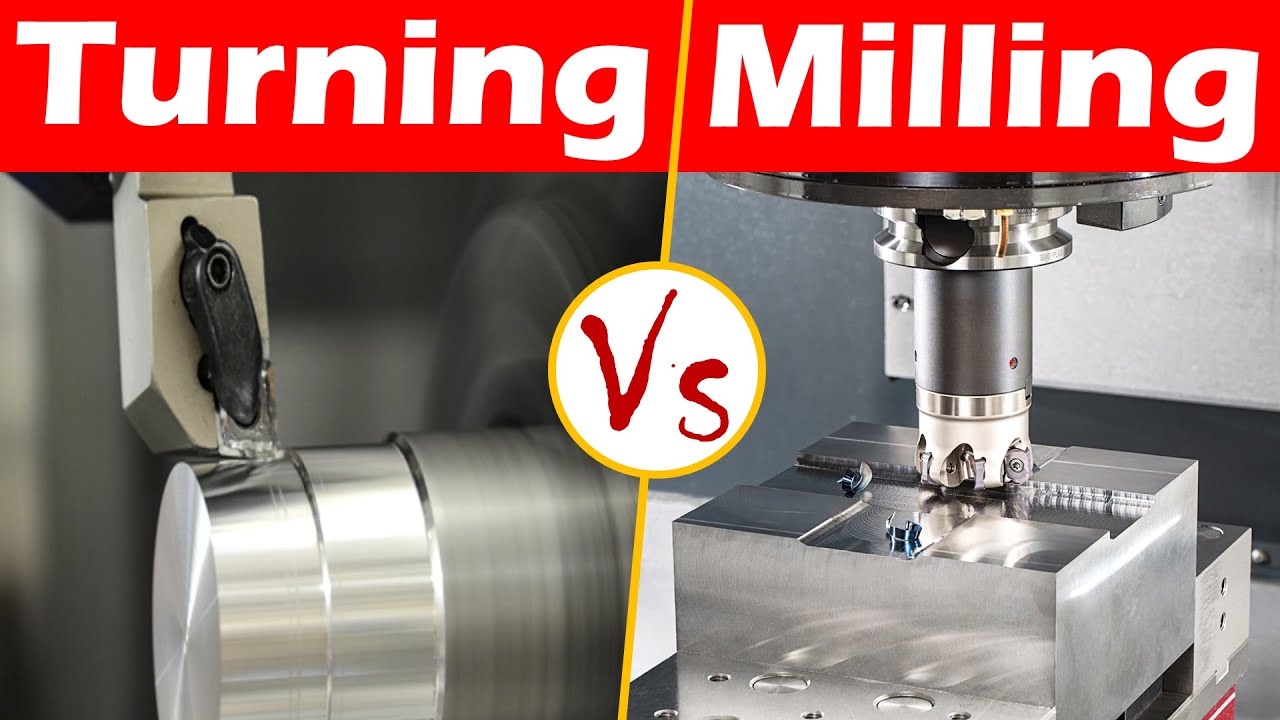

Comparing Turning And Milling Techniques Strappack As a cutting process, drilling is considered to be one of the more cost effective solutions for metal machining. milling. milling is done using multi point rotary cutters. these cutters remove material from a piece. face milling and peripheral milling are your two main choices here: face milling cuts flat surfaces, either horizontally or vertically. Drilling produces a round hole in a workpiece. a tapping or drill press machine performs drilling operations. however, drilling can also be handled with a milling machine. when machining a workpiece, chips are the waste material produced during the machining process. the way the drill bit is shaped enables chips to fall away from the workpiece. Thread milling using either solid carbide thread mills or steel holders with indexable inserts. solid carbide thread mill: useful for smaller hole sizes, more expensive than indexable tools, but can be cost effective depending on the quality needed. indexable insert thread mill: not fit in holes that are 0.625 inches or less in diameter. once. Speed: as a rule, tapping is slightly faster than thread milling. depending on the workpiece material, thread depth, and machine tool speed, the 1 4" 20 thread discussed so far might take 4 5 seconds to tap, and perhaps twice that to mill with a full profile cutter. yes, single plane thread mills with their need to make multiple passes are far.

Comments are closed.