Comparing Turning And Milling Techniques Strappack

Comparing Turning And Milling Techniques Strappack Title: discovering the distinctions between turning and milling unraveling the secrets of metalworking operations description: overview: this video covers a detailed discussion on the major differences between turning and milling operations. subscribe to our channel for a comprehensive understanding of metalworking techniques and enhance your skills in the field…. 2. turning: witness the magic of turning as the lathe effortlessly shapes cylindrical objects, creating smooth and uniform diameters along their length. 3. knurling: discover the technique of knurling, which adds texture and grip to cylindrical surfaces, making them easier to handle and manipulate. 4.

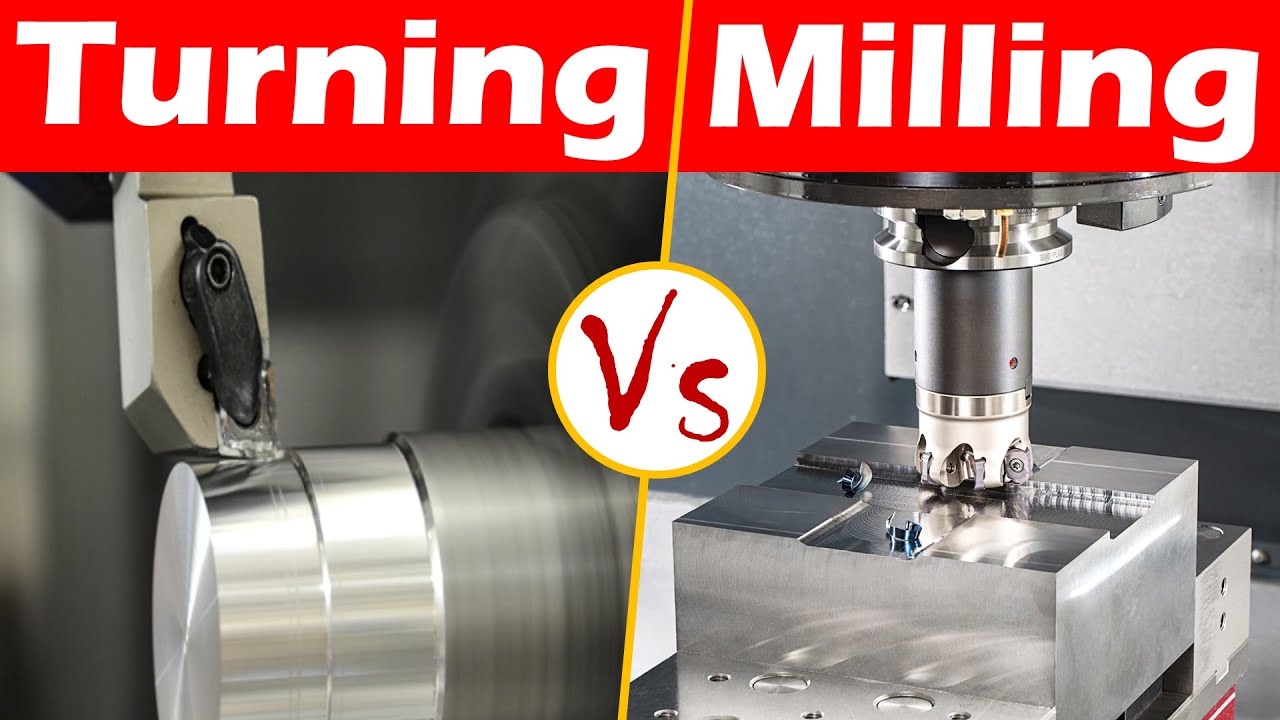

Smartlathe Cnc Complex Turning Milling Configuration Strappack Introduction: welcome to an exciting video showcasing the incredible capabilities of the smartlathe cnc turning & milling complex configuration. in this video, we delve into the world of advanced cnc technology, highlighting the exceptional precision, versatility, and speed that this cutting edge machine offers. Milling and turning are types of precision machining that remove material from a workpiece. the main difference lies in the movement of the workpiece and cutting tool. turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. Turning and milling are two common machining processes that remove material from a workpiece with the assistance of a cutting tool. while similar, though, they use different methods to achieve this goal. turning forces the workpiece to rotate, whereas milling forces the cutting tool to rotate. with different mechanism, they each offer unique. Cnc milling is ideal for parts with complex geometries, including slots, holes, and irregular surfaces. it is suitable for projects requiring detailed features on multiple surfaces. cnc turning is best for round or cylindrical parts like rods, shafts, and bushings. it is preferred for parts requiring precise circular diameters and tubular shapes.

Video Demonstrating Cnc Turning And Machining Processes Strappack Turning and milling are two common machining processes that remove material from a workpiece with the assistance of a cutting tool. while similar, though, they use different methods to achieve this goal. turning forces the workpiece to rotate, whereas milling forces the cutting tool to rotate. with different mechanism, they each offer unique. Cnc milling is ideal for parts with complex geometries, including slots, holes, and irregular surfaces. it is suitable for projects requiring detailed features on multiple surfaces. cnc turning is best for round or cylindrical parts like rods, shafts, and bushings. it is preferred for parts requiring precise circular diameters and tubular shapes. A mill turn center is essentially a hybrid machine that uses the tool rotation of milling and the workpiece rotation of turning. mill turn allows users to machine more complex parts without switching machining centers and in much less time. the average mill turn center can complete four operations to every one performed by a mill or lathe. Key differences. operation: turning involves the rotation of the workpiece, while milling involves the rotation of the cutting tool. tooling: turning primarily uses single point cutting tools, while milling employs multi point cutting tools, such as end mills and face mills. workpiece geometry: turning is best suited for cylindrical parts.

Cnc Lathe Project Enhancing Precision And Efficiency In Turning A mill turn center is essentially a hybrid machine that uses the tool rotation of milling and the workpiece rotation of turning. mill turn allows users to machine more complex parts without switching machining centers and in much less time. the average mill turn center can complete four operations to every one performed by a mill or lathe. Key differences. operation: turning involves the rotation of the workpiece, while milling involves the rotation of the cutting tool. tooling: turning primarily uses single point cutting tools, while milling employs multi point cutting tools, such as end mills and face mills. workpiece geometry: turning is best suited for cylindrical parts.

Incredible Metal Cutting Machine Turning Milling And More Strappack

New Approach To Turning Strappack

Comments are closed.