Common Industrial Die Cutting Mistakes To Avoid Sbl

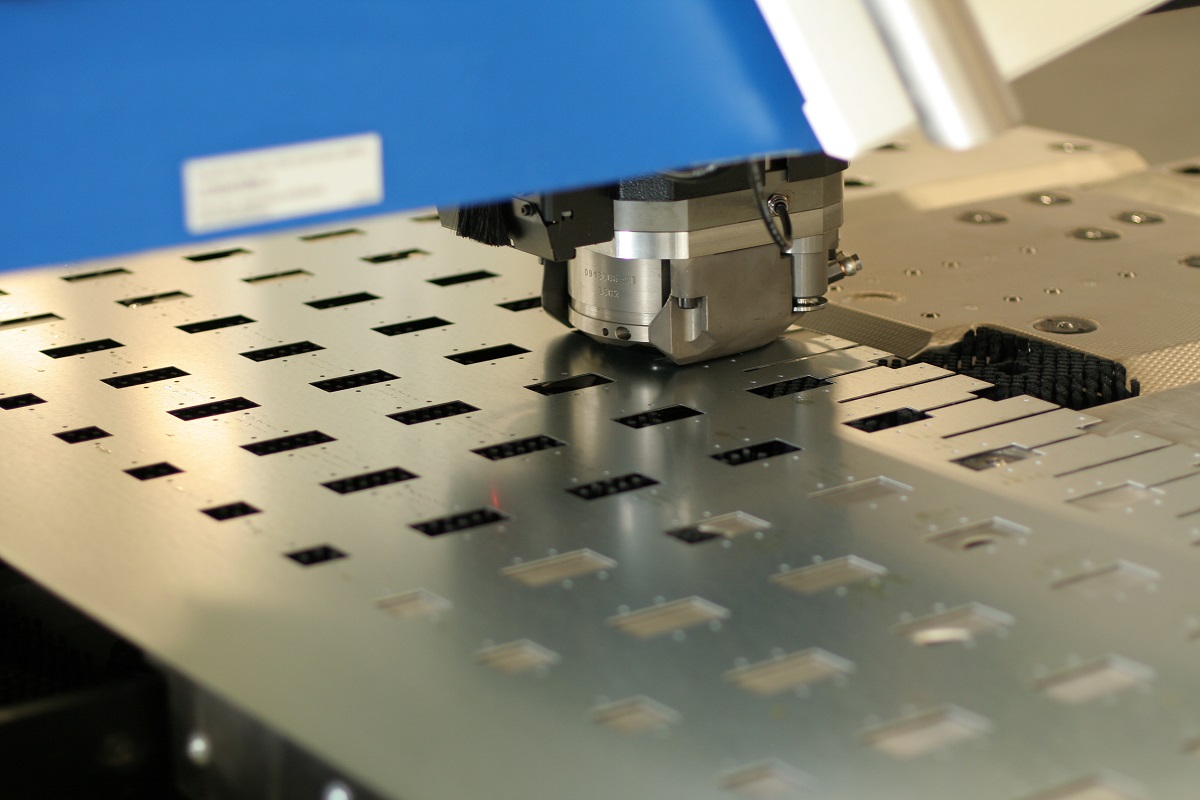

Common Industrial Die Cutting Mistakes To Avoid Sbl Sbl is an award winning provider of die cutting machines used worldwide. you’ll get high quality products for mass production of packaging products and die cut sheets. for reliable, safe and efficient equipment for your business, choose sbl machines. for inquiries, call us today at 886 2 2680 2199 or fill out our online form. Pros of flatbed die cutting. cuts through thicker, denser materials because of its great cutting pressures. works on thin materials while ensuring sharp, precise cuts. has low tooling and machine costs, making it an affordable option. can group parts closely on the sheet, reducing trimmings and scrap materials.

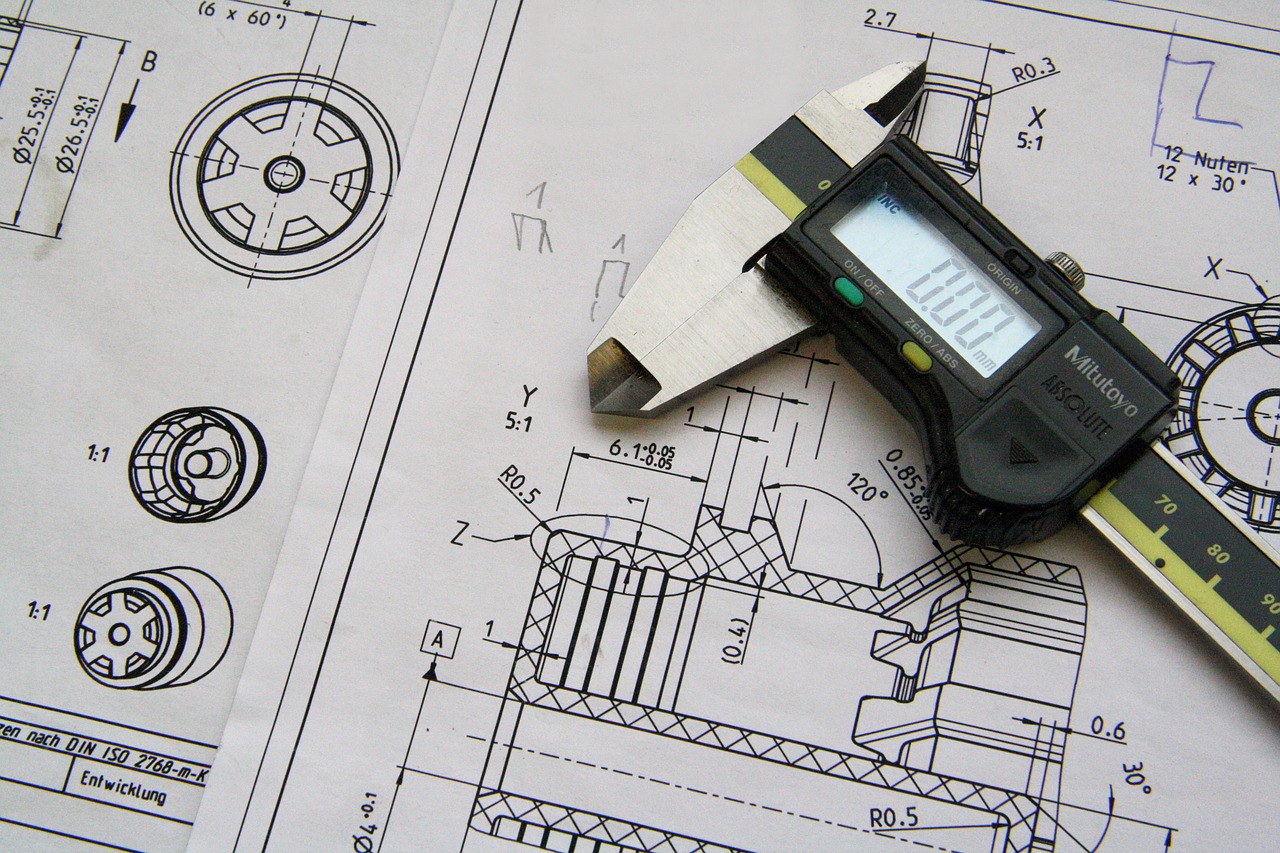

Common Industrial Die Cutting Mistakes To Avoid Sbl Call a technician to inquire about more affordable alternative solutions. 6. general wear and tear. the outermost edges of the blade grow dull when the die blades always come into contact with metal. at the same time, the clearance between the anvil and die cutting cylinders should be properly calibrated. Customizability: while affordable, die cutting also allows for customizable cuts. laser and steel rule die cutting can adapt to any shape needed. flexibility: there are many materials this process can cut, including metals and wood. the wide variety of projects that can use die cutting makes it a flexible manufacturing process. Download the full version of the 5 common design mistakes here. the product development team at cgr products frequently encounter designs with thin flange widths or difficult hole placement. while cutting processes are precise enough to create these holes, all materials have limitations. Mistake #1 not specifying machining tolerances. the process of manufacturing a die cut gasket is very different than machining a metal part and requires much wider tolerances. production techniques, tool type, part features, and material type are all considerations in die cutting techniques.

How To Fix Common Die Cutting Machine Issues Sbl Download the full version of the 5 common design mistakes here. the product development team at cgr products frequently encounter designs with thin flange widths or difficult hole placement. while cutting processes are precise enough to create these holes, all materials have limitations. Mistake #1 not specifying machining tolerances. the process of manufacturing a die cut gasket is very different than machining a metal part and requires much wider tolerances. production techniques, tool type, part features, and material type are all considerations in die cutting techniques. Incorrectly placing the material on the die can lead to misaligned or partially cut shapes. to avoid this, always position your material precisely over the cutting lines of the die. use low tack tape or magnetic sheets to hold the materials in place during cutting, ensuring that they don't shift or slide. overloading the machine: overloading. Die cut gaskets are used for a variety of applications, with some of the most common uses being environmental seals and emi shielding. while there are many gasket manufacturing methods to choose from based on your application needs, the die cutting process offers a variety of unique benefits: • fast gasket production.

3 Common Die Cutting Mistakes How To Avoid Them Kra Fab Incorrectly placing the material on the die can lead to misaligned or partially cut shapes. to avoid this, always position your material precisely over the cutting lines of the die. use low tack tape or magnetic sheets to hold the materials in place during cutting, ensuring that they don't shift or slide. overloading the machine: overloading. Die cut gaskets are used for a variety of applications, with some of the most common uses being environmental seals and emi shielding. while there are many gasket manufacturing methods to choose from based on your application needs, the die cutting process offers a variety of unique benefits: • fast gasket production.

Comments are closed.