Cms Epicor Cost Rollup

Cms Epicor Cost Rollup Youtube Goes through on how to do a cost roll up. For the part in the first picture, the bom cost report shows (no zero’s anywhere) material costs: .161. labor cost: .05238. total cost: .21338. as you can see they are different than what is in the part tracker. kinda lost on how the bom is one number and part tracker is completely different.

Epicor Cms Pricing Alternatives More 2023 Capterra Tsmith (tyler smith) december 29, 2021, 8:22pm 5. wip uses the cost of transactions at the time they occur. as in, whenever you issue material, apply labor, or receive subcontract parts, epicor uses the cost of that labor or material or subcontract po at the time of the transaction. when you ship the finished parts or receive them to inventory. The screen shot above is from the costing workbench for me. i always un check the “consider pull as assembly settings” because i don’t want lower level mfg. parts rolling all the material , labor and burden costs in to the material of the top level. Use the costing workbench to: select the top level parts for cost rollup. load the related cost details for sub assemblies, raw materials, burden rates and labor rates. check for unapproved part revisions. adjust the cost of purchased parts. as needed. perform the cost rollup. review the resulting standard costs. Finally, i added the material cost per unit which is $174.78 and got an expected new cost of $946.89. however, the system calculated the new cost as $914.86. if i subtract the material cost of $174.78, i am left with $740.08 or $914.86 $174.78 = $740.08. i then divide that by the labor and burden rate of $179.98 and have a total hrs per unit of.

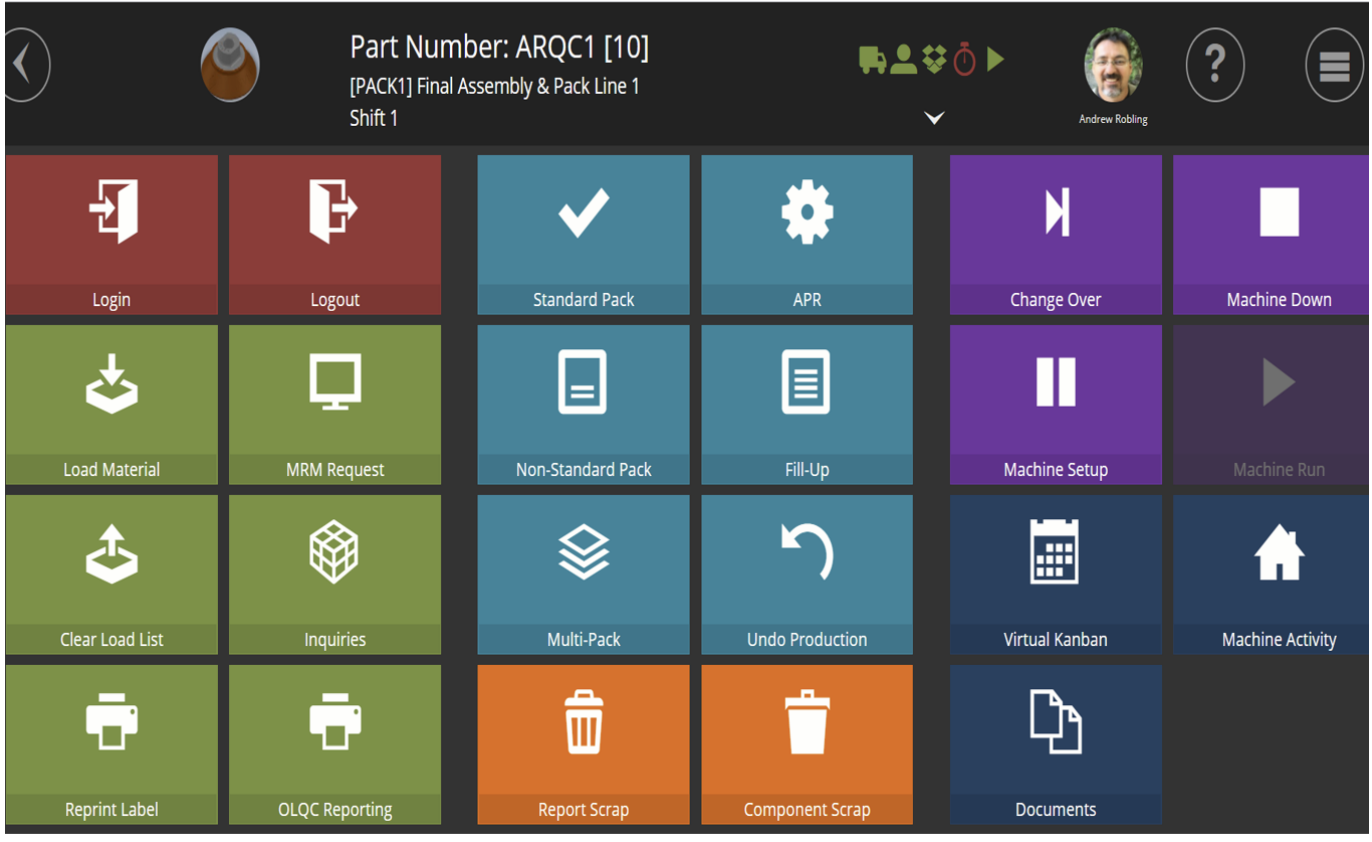

Epicor Cms Pricing Reviews 2022 Erp Software Use the costing workbench to: select the top level parts for cost rollup. load the related cost details for sub assemblies, raw materials, burden rates and labor rates. check for unapproved part revisions. adjust the cost of purchased parts. as needed. perform the cost rollup. review the resulting standard costs. Finally, i added the material cost per unit which is $174.78 and got an expected new cost of $946.89. however, the system calculated the new cost as $914.86. if i subtract the material cost of $174.78, i am left with $740.08 or $914.86 $174.78 = $740.08. i then divide that by the labor and burden rate of $179.98 and have a total hrs per unit of. A product or assembly item may be made up of certain materials or sub assembly items and therefore requires a multi level bom. epicor has the functionalities to define different levels of bom and to calculate the cost with rollup options. with an epicor erp solution, the manufacturing details can be prepared in different stages. Epicor cms is a purpose built erp solution for automotive manufacturers, with tools and controls that meet the strict delivery requirements and rigorous production deadlines that your customers demand. reduce shipping errors and tighten inventory accuracy with serialized inventory tracking. gain clear shop floor visibility using lot sensors to.

Comments are closed.