Check Valves Essential Guide Aquatech

Check Valves Essential Guide Aquatech Check valves are a common sight in industrial systems and are used to remove wastewater and other contaminated fluids. check valves feature a single inlet and outlet where water can pass through it but not back up it, and it is operated by a pressure differential, according to proco products. a pressure differential, in the context of check. Swing type check valves permit water to flow backwards through the piping system as the valve closes, risking water hammer problems or even equipment damage. [1] our photos above show a typical brass well piping check valve. a spring loaded internal valve permits water to flow through the valve only in one direction.

Aquatech Check Valves Essential Guide Check valves are used in a wide range of applications to prevent backflow and protect equipment. common uses include: protecting pumps and compressors from damage caused by reverse flow. maintaining system pressure by allowing flow only in one direction. ensuring proper operation of equipment like boilers, pipelines, and irrigation systems. Check the electricity. if the sump pump does not seem to be working at all, check the electrical connections. make sure the pump is plugged in properly, and check the circuit breaker. pay special attention to the ground fault circuit interrupter if your pump is connected to one, as these have a tendency to trip. press the reset button on the gfci. An essential element in the design of water and wastewater pumping systems is the proper selection of the pump discharge check valve, whose purpose is to automatically open to allow forward flow and automatically return to the closed position to prevent reverse flow when the pump is not in operation. another function that is often overlooked is. A check valve, often referred to as a non return valve, retention valve, or one way valve, serves as a critical component allowing fluid to flow in only a singular direction. comprising two openings or ports—the inlet, where fluid enters, and the outlet, where fluid exits—the check valve plays a pivotal role in preventing the undesirable.

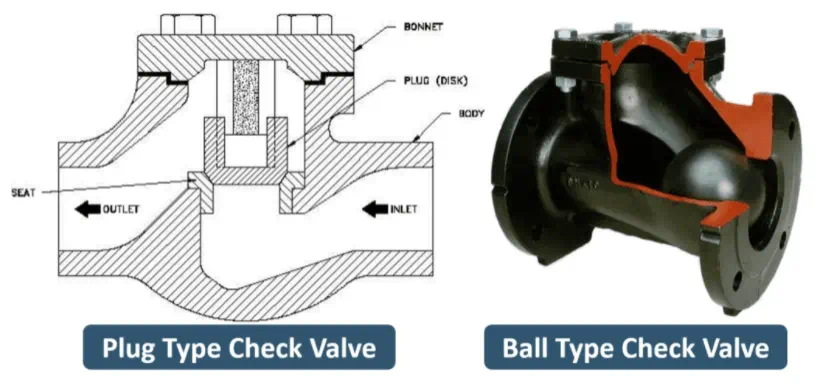

Check Valves Essential Guide Aquatech An essential element in the design of water and wastewater pumping systems is the proper selection of the pump discharge check valve, whose purpose is to automatically open to allow forward flow and automatically return to the closed position to prevent reverse flow when the pump is not in operation. another function that is often overlooked is. A check valve, often referred to as a non return valve, retention valve, or one way valve, serves as a critical component allowing fluid to flow in only a singular direction. comprising two openings or ports—the inlet, where fluid enters, and the outlet, where fluid exits—the check valve plays a pivotal role in preventing the undesirable. A check valve, also known as a non return or one way valve, is a two port safety device that allows gas, steam, or fluid to flow in a single direction. its primary purpose is to restrict backflow in a system. there are a variety of check valve stopping mechanisms, including a disc, piston, or ball. The key to preventing check valve failure and ensuring valve longevity is proper and regular preventative maintenance. the first and most effective step for avoiding valve failure is keeping the pipeline and valves clean and free of debris. this can be achieved by installing filters and covers where required.

Check Valves Essential Guide Aquatech A check valve, also known as a non return or one way valve, is a two port safety device that allows gas, steam, or fluid to flow in a single direction. its primary purpose is to restrict backflow in a system. there are a variety of check valve stopping mechanisms, including a disc, piston, or ball. The key to preventing check valve failure and ensuring valve longevity is proper and regular preventative maintenance. the first and most effective step for avoiding valve failure is keeping the pipeline and valves clean and free of debris. this can be achieved by installing filters and covers where required.

Aquatech Check Valves Essential Guide

Comments are closed.