Chamfer Drill

Drill Chamfer Back Chamfer Tool Youtube Step chamfer holes in one pass. the challenge when using a multidiameter tool is to achieve good chip breaking from all edges in the cut. in long chipping materials, such as low carbon steels and stainless steels, the initial tests should be made in steps: first, check chip formation from the drill. check chip formation from step insert. End mills. cut and shape material to create precise slots, grooves, and profiles. 16 products. choose from our selection of chamfering drill bits, including over 2,400 products in a wide range of styles and sizes. in stock and ready to ship.

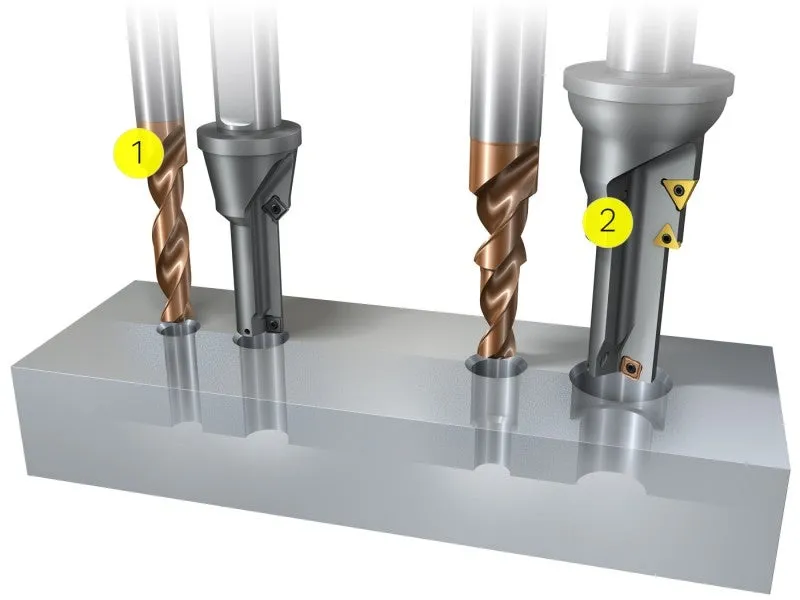

Tips For Step And Chamfer Drilling By Sandvik Coromant Corodrill ® 880 step and chamfer drill option 1. chamfer. option 2. step 90° option 3. step <90° options. available with one extra insert, either step or chamfer; drill lengths up to 3 × diameter (dc1 & dc2) drill diameter range (dc1): 12.0–63.5 mm (0.472−2.500 inches) step diameter (dc2) 20.7−85.0 mm (0.815−3.346 inches) coupling. Discover combination chamfer & countersink drills at msc industrial supply. over 1 million products that ship and deliver fast. Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. this slope is generally machined at a 45 degree angle, but the angle may vary depending. Carbide tipped double chamfer end mills. these carbide tipped end mills provide a sharper, harder cutting edge and better wear resistance than high speed steel without the brittleness of solid carbide. their teeth are angled on both sides so you can make top and bottom chamfer cuts without having to flip the workpiece.

Using A Spot Drill To Chamfer The Outside Of A Part Youtube Chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. this slope is generally machined at a 45 degree angle, but the angle may vary depending. Carbide tipped double chamfer end mills. these carbide tipped end mills provide a sharper, harder cutting edge and better wear resistance than high speed steel without the brittleness of solid carbide. their teeth are angled on both sides so you can make top and bottom chamfer cuts without having to flip the workpiece. Chamfering 101. a chamfer is a specific type of edge. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. a chamfer edge is made up of a flat edge meeting a 45 degree angle. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Chamfered holes and spot drills for chamfering. most holes and especially tapped holes benefit from a chamfer to clean up an burrs and ensure a clean start for threads. rather than using a conventional chamfer mill, holes are usually chamfered using a spot drill so the same tool can be used to spot the hole as well as to chamfer it.

6pcs Hss Chamfer Countersink Chamfer Drill Bit 1 4 Hex Shank 90 Degree Chamfering 101. a chamfer is a specific type of edge. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. a chamfer edge is made up of a flat edge meeting a 45 degree angle. a chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Chamfered holes and spot drills for chamfering. most holes and especially tapped holes benefit from a chamfer to clean up an burrs and ensure a clean start for threads. rather than using a conventional chamfer mill, holes are usually chamfered using a spot drill so the same tool can be used to spot the hole as well as to chamfer it.

Gold Twist Chamfer Drill

Comments are closed.