Centrifugal Pump Failures During First Year Operation Pdf Pump

Centrifugal Pump Failures During First Year Operation Download Free Section 2.0: centrifugal pump problems 5 overview of pump problems typically found on centrifugal pumps. 2.1 no or low flow 7 2.2 no or low pressure 14 2.3 excessive power consumption 15 2.4 excessive noise or vibration 16 2.5 seal leakage 20 section 3.0: alfa laval solutions to specific centrifugal pump problems 31. Application of centrifugal pumps is provided by sembler (1999). the primary purpose of many of the components listed below is to perform a hydraulic function, i.e., produce flow and head at an acceptable efficiency. however, these components also affect pump integrity and reliability. 157 av oiding failures in centrifugal pumps by william d.

Centrifugal Pump Problems Pdf Pdf Pump Bearing Mechanical The document discusses centrifugal pump failures that occur during the first year of operation. it notes that failure rates are highest upon installation and remain elevated during the first year as pumps are in the early life failure region of the bathtub curve. some of the main causes of early life failures discussed include issues with engineering design, manufacturing, testing and. Common centrifugal pump problems and solutions. whether you’re dealing with reduced flow, abnormal noises, or leaks, we’ve got you covered. 1. reduced flow or low flow rate. problem: reduced flow can be caused by clogs, blockages, or wear and tear on impellers. solution: inspect and clean the pump’s inlet and impeller, and consider. The operating principle of the pump is to convert mechanical energy to pressure. in operation, a rotating impeller accelerates a liquid and as the area of the pump casing expands the velocity of the fluid is converted to pressure. as a result pressurized fluid exits the pump discharge. Kristoffer k. mckee, gareth forbes, ilyas mazhar, rodney entwistle and ian howard curtin university, western australia. summary: centrifugal pumps are one of the world’s most widely used type of pump, having an extensive range of applications, from food processing to water or sewage transportation. problems that arise within these machines.

Problem Solving Centrifugal Pumps Pdf Pump Leak The operating principle of the pump is to convert mechanical energy to pressure. in operation, a rotating impeller accelerates a liquid and as the area of the pump casing expands the velocity of the fluid is converted to pressure. as a result pressurized fluid exits the pump discharge. Kristoffer k. mckee, gareth forbes, ilyas mazhar, rodney entwistle and ian howard curtin university, western australia. summary: centrifugal pumps are one of the world’s most widely used type of pump, having an extensive range of applications, from food processing to water or sewage transportation. problems that arise within these machines. The system for the reliability analysis is called “stand by redundancy” type 1 of 2, just one pump is in operating mode and the other pump is waiting for failure of the first pump. these are two stage centrifugal pumps type (wtb) vertically splited; they are designed for heavy duty in refineries, electric centrals and for general services. Working mechanism of a centrifugal pump. a centrifugal pump is one of the simplest pieces of equipment in any process plant. its purpose is to convert energy of a prime mover (a electric motor or turbine) first into velocity or kinetic energy and then into pressure energy of a fluid that is being pumped.

Centrifugal Carbamate Pump Failures Improvement Pdf Pdf Bearing The system for the reliability analysis is called “stand by redundancy” type 1 of 2, just one pump is in operating mode and the other pump is waiting for failure of the first pump. these are two stage centrifugal pumps type (wtb) vertically splited; they are designed for heavy duty in refineries, electric centrals and for general services. Working mechanism of a centrifugal pump. a centrifugal pump is one of the simplest pieces of equipment in any process plant. its purpose is to convert energy of a prime mover (a electric motor or turbine) first into velocity or kinetic energy and then into pressure energy of a fluid that is being pumped.

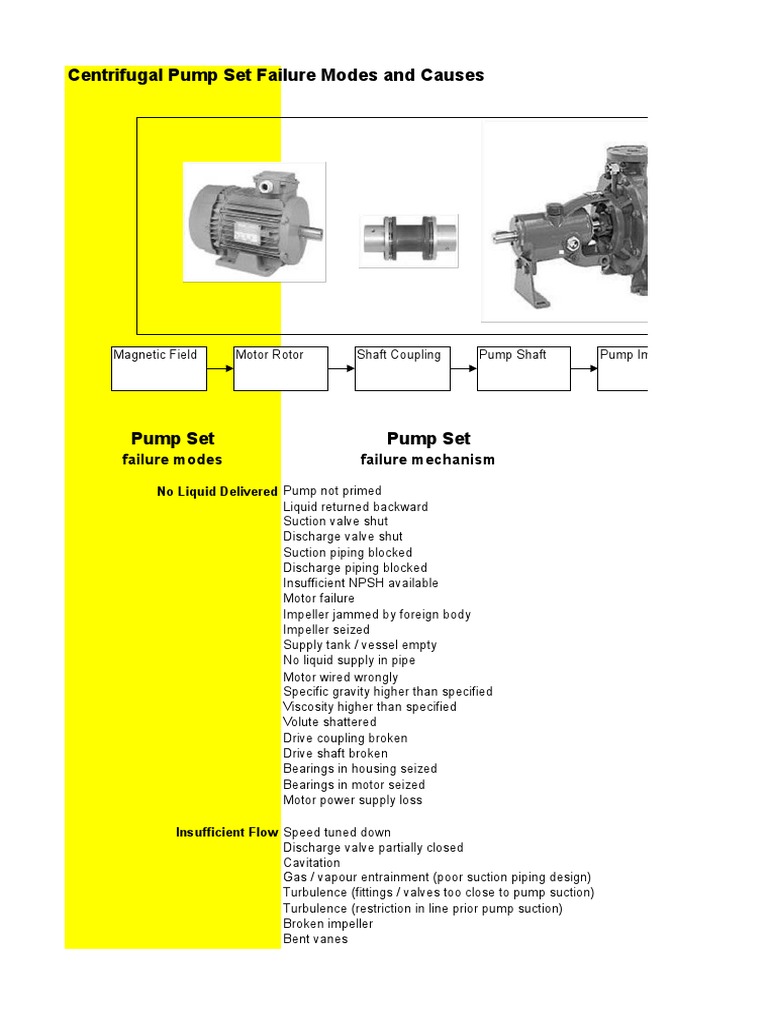

Centrifugal Pump Set Failure Modes Pdf

Comments are closed.