Cast Vs Forged Parts Why Cast Is Bad And Why Forged Is Better

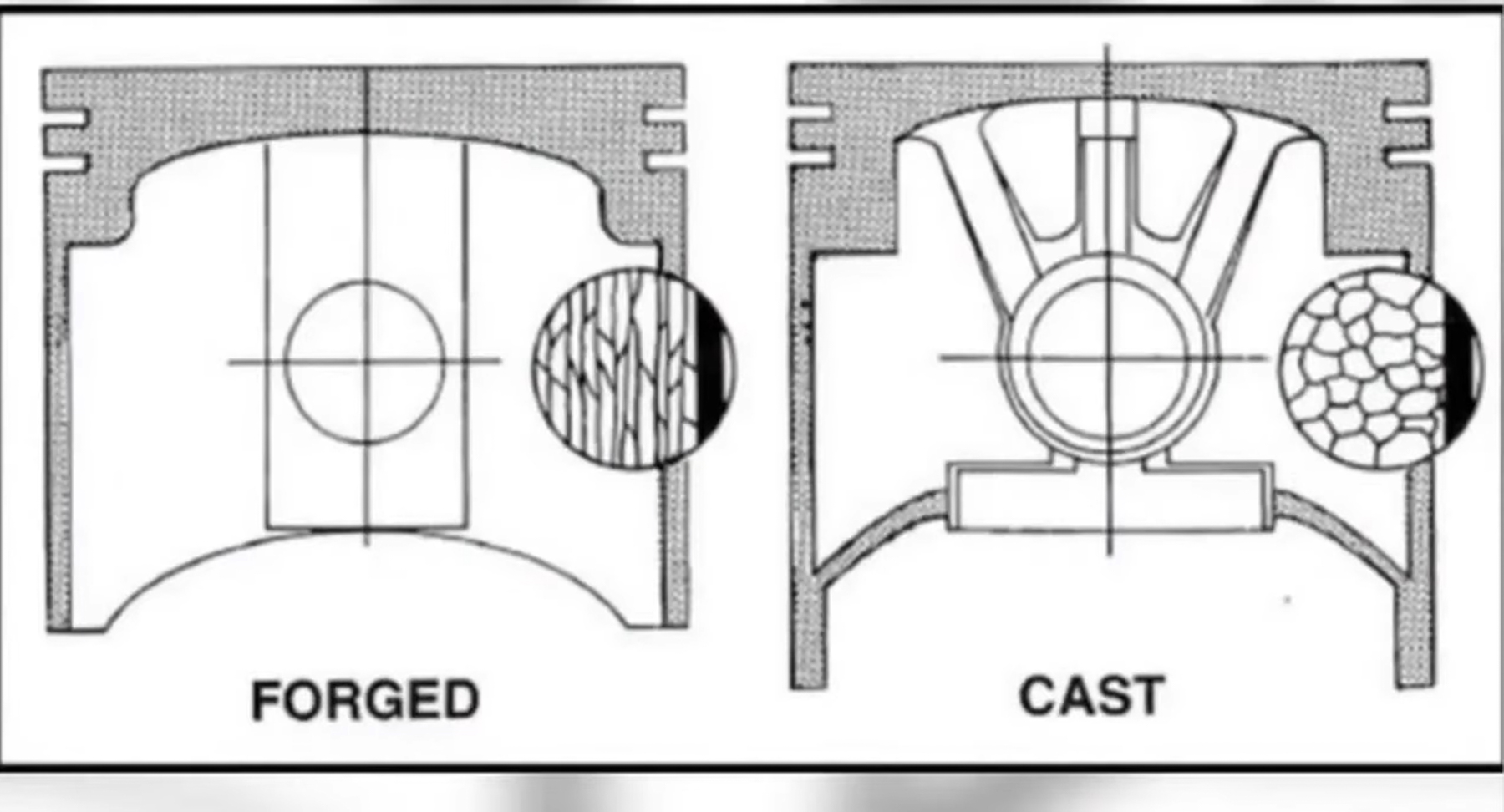

The Basics Of Forged Vs Cast Pistons Vcp Motorsports Forged parts had a 37% higher fatigue strength resulting in a much longer lifespan than cast parts. cast iron only had 66% of the yield strength of forged steel, a measurement that indicates the load amount metal can hold before deforming. the forged parts had a 58% reduction in area when pulled to failure, compared to 6% reduction for cast parts. Advantages of casting. while forging will give you stronger parts, there are a lot of reasons why casting might be the method of choice. for one, casting is generally much cheaper. instead of complicated dies, you can make simpler moulds. these can be made from a number of materials, but sand is a common and cheap one.

Forged Vs Cast What S The Difference Cornell Forge Co Forging typically produces parts with fewer internal voids and improved material density. production speed. casting is often faster for mass production of intricate shapes. forging tends to be slower due to the individual shaping process, suitable for lower volume production of high strength parts. tooling costs. A forged crankshaft emerges from the press. one advantage of forging is that it forces the grain structure of the combined metals to reform (i.e. crystallize) without losing shape, which means the finished product will be much more sturdy and reliable than a cast one. forged pieces also respond better to heat treating, where cast pieces can. Last but not least, cast and forged parts may be assembled, welded, brazed, and hard faced before being shipped as final products. the products resulting from casting and forging processes have different properties in terms of surface porosity (generally better for forged vs. cast products), grain structure (finer for forged products), tensile. Forged parts are characterized as having high tensile and fatigue strength over cast parts, although how much is up for debate. the most cited study on forged and cast part strength is also taken out of context. the university of toledo concluded that forged steel had 26% tensile strength and 37% greater fatigue strength over cast iron— iron.

Cast Vs Forged Parts Why Cast Is Bad And Why Forged Is Better Youtube Last but not least, cast and forged parts may be assembled, welded, brazed, and hard faced before being shipped as final products. the products resulting from casting and forging processes have different properties in terms of surface porosity (generally better for forged vs. cast products), grain structure (finer for forged products), tensile. Forged parts are characterized as having high tensile and fatigue strength over cast parts, although how much is up for debate. the most cited study on forged and cast part strength is also taken out of context. the university of toledo concluded that forged steel had 26% tensile strength and 37% greater fatigue strength over cast iron— iron. A forged steel fitting will therefore withstand a lot more force and be more durable under different stresses. you may still need to use casting, however, in the following situations: the part you need is too large to forge. the part you are forging needs custom alloys added to it. the part is too complicated to forge successfully. Cast vs. forged steel: key differences casting process. it functions at a temperature above that of melting. casting is better and easier for complex parts. casted parts are more expensive but very precise. the process of casting is semi automated. heat treatment causes a non uniform response in the casting process.

Forged Vs Cast Does It Even Matter Mygolfspy A forged steel fitting will therefore withstand a lot more force and be more durable under different stresses. you may still need to use casting, however, in the following situations: the part you need is too large to forge. the part you are forging needs custom alloys added to it. the part is too complicated to forge successfully. Cast vs. forged steel: key differences casting process. it functions at a temperature above that of melting. casting is better and easier for complex parts. casted parts are more expensive but very precise. the process of casting is semi automated. heat treatment causes a non uniform response in the casting process.

Cast Vs Forged Steel What S The Difference

Gun Parts Forged Vs Cast Vs Mim Which Is Better Youtube

Comments are closed.