Aw Extra 7 5 12 Tips For Building Cabinets With Pocket Hole Joinery

Aw Extra 7 5 12 Tips For Building Cabinets With Pocket Hole Joinery Step 4: attach back cleat. this is what you will use to secure the cabinet to the wall after everything is all leveled. drive 3″ cabinet screws through this cleat into the studs. use wood glue and 1 1 4″ pocket hole screws. Dado cabinets will hold more downward force than pocket screws or mortise and loose tenon, because you have the full strength of the wood involved with a dado in that direction, rather than the 1 2 surrounding the screw, for instance. pocket screws are easiest fastest, and pretty strong as well.

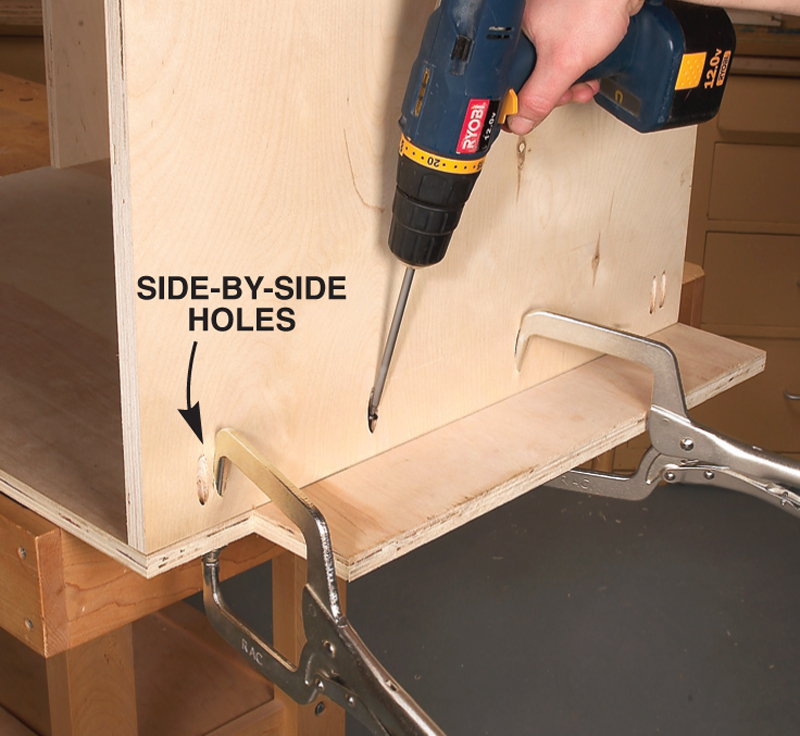

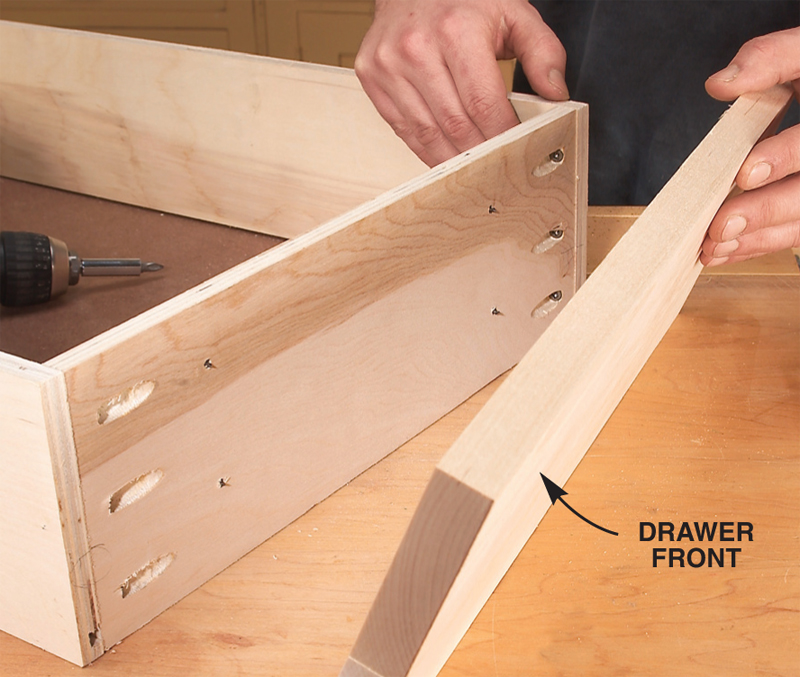

Aw Extra 7 5 12 Tips For Building Cabinets With Pocket Hole Joinery Ed pirnik, cari delahanty. thanks to the invention of the pocket hole joinery system, it’s easy for novice and veteran woodworkers alike to construct strong, attractive cabinetry using any number of inexpensive jigs. like a toenail in carpentry, a pocket screw goes into the side of one board at an angle, and then down into the board below. Use double faced carpet tape or hot melt glue to temporarily secure the drawer front to the drawer box. gently open the drawer and clamp the front to the box. attach it with four no. 8 x 1 1 4 in. pan head screws with no. 10 finish washers under the heads. snug the screws but don’t tighten them. Pocket hole joinery is just assembling two pieces of wood together with screws. first, you drill an angled pilot hole into the wood around half an inch from the edge. after you finish drilling a counterbore, you can fit a screw in the room available. it allows for a solid hold for the adjoining material. Here are my best tips and answers to frequently asked questions and problems when using pocket hole joinery –. 1. measure the thickness of materials. and then measure again! this is very important to make sure all your settings are set correctly for the material you are using. never assume.

Aw Extra 7 5 12 Tips For Building Cabinets With Pocket Hole Joinery Pocket hole joinery is just assembling two pieces of wood together with screws. first, you drill an angled pilot hole into the wood around half an inch from the edge. after you finish drilling a counterbore, you can fit a screw in the room available. it allows for a solid hold for the adjoining material. Here are my best tips and answers to frequently asked questions and problems when using pocket hole joinery –. 1. measure the thickness of materials. and then measure again! this is very important to make sure all your settings are set correctly for the material you are using. never assume. I have had my massca m2 pocket hole jig for over a year now, since i first used it to build the wainscoting in my son’s nursery. i love how durable, well made, and easy to use it is, and i can’t wait to share how i used it for my cabinet builds! design planning. the first step in building cabinets is to determine what size you’d like. The jigs. as i mentioned, what makes pocket hole joinery possible is the use of a specialized jig (and bit) to drill the holes. in order for the screw to make the connection, the pocket holes have to be drilled at a precise angle of 15º. it isn't practical to attempt this freehand or even on the drill press.

Comments are closed.