Asme B16 9 Elbow Hot Forming

Asme Ansi B16 9 Elbow Dimensions Chart Grow Mechanical 1. hot push forming. the hot push asme b16.9 pipe elbow forming process is the process of using a dedicated elbow pushing machine, core mold, and heating equipment to move the blank on the mold forward under the push of the pushing machine, which is heated, expanded, and twisted into shape during the movement. Standard drawing of asme b16.9 90° & 45° long radius (l r) elbows. the asme b16.9 elbow is used when a pipe changes direction. elbows can turn up, turn down, turn left, right, or any angle in between. the long radius (l r) elbows denote elbows with the center to end dimension of 1.5d radius which equals to 1.5 x nps in inch unit.

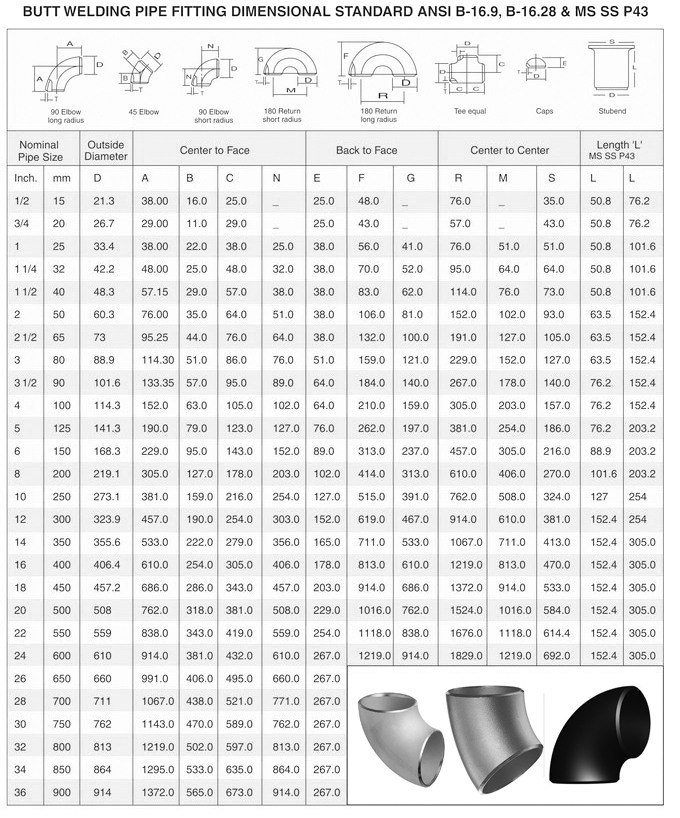

Asme B16 9 Elbow Ansi B16 9 Elbow B16 9 Pipe Elbows Manufacturers Standard drawing of asme b16.9 3d radius elbow. according to asme b16.9 2018, the standard 3d radius elbow may be furnished in 45° or 90°. compared to the long radius elbow, its center to end dimension is much larger, which is double the length of a corresponding l r elbow. the center to end dimension can be calculated as “3 x nps” in. Buttweld fittings are pipe fittings used to change the pathway of a pipeline (elbows), reduce increase the pipe bore size (reducers), branch (tees, cross), or blind a pipeline (butt weld cap). asme b16.9 (and mss sp 43) buttweld fittings are used for piping systems above 2 inches in diameter, whereas socket weld and threaded fittings (“forged. One of the most common elbow manufacturing processes for manufacturing elbows from the pipe is mandrel method which is kind of hot forming methods. asme b16.9 astm a403 wp304 long radius elbows in this method, a pipe is cut in pieces and push with the help of hydraulic ram. Asme b16.9 2018 (revision of asme b1 6.9 201 2) factory made wrought buttwelding fittings a n a m e r i c a n n at i o n a l s ta n d a r d asme b16.9 2018 (revision of asme b16.9 2012) factory made wrought buttwelding fittings an american national standard x date of issuance: october 29, 2018 the next edition of this standard is scheduled for.

Hot Rolled Cold Rolled Jis B2311 Iso 3419 Asme B16 9 Elbow Pipe Elbow One of the most common elbow manufacturing processes for manufacturing elbows from the pipe is mandrel method which is kind of hot forming methods. asme b16.9 astm a403 wp304 long radius elbows in this method, a pipe is cut in pieces and push with the help of hydraulic ram. Asme b16.9 2018 (revision of asme b1 6.9 201 2) factory made wrought buttwelding fittings a n a m e r i c a n n at i o n a l s ta n d a r d asme b16.9 2018 (revision of asme b16.9 2012) factory made wrought buttwelding fittings an american national standard x date of issuance: october 29, 2018 the next edition of this standard is scheduled for. Asme b16.9 90° elbows l r sch80 dn500, astm a234 gr. wp22, for a coal fired power plant in south africa. the butt welding fittings shall be manufactured by a “wrought” process denoting that fittings made of pipe, tubing, plate, or forging. the fittings can be made from a hot forming or cold forming process, in welded or seamless pipe. The asme b16.9 standard is a crucial reference for the piping industry. it provides detailed specifications for factory made, wrought butt weld fittings, which are essential for connecting pipes in various industrial applications.

Asme B16 9 Seamless Fittings Elbow By Dinesh Industries Asme b16.9 90° elbows l r sch80 dn500, astm a234 gr. wp22, for a coal fired power plant in south africa. the butt welding fittings shall be manufactured by a “wrought” process denoting that fittings made of pipe, tubing, plate, or forging. the fittings can be made from a hot forming or cold forming process, in welded or seamless pipe. The asme b16.9 standard is a crucial reference for the piping industry. it provides detailed specifications for factory made, wrought butt weld fittings, which are essential for connecting pipes in various industrial applications.

Ansi B16 9 Elbow Engineering Tolerance Pipe Fluid Conveyance

Asme B16 9 Short Radius Elbows

Comments are closed.