Api 6d Hydro Static Valve Testing Procedure How To Test An Api 6d Valve Pipeline Valve Testing

Api 6d Hydro Static Valve Testing Procedure How To Test An Api 6d The test pressure for the hydrostatic shell test shall be a minimum of 1.5 times the pressure rating conforming to 4.3 for material at 100 °f (38 °c) based on the valve end connector material. the test duration shall conform to table 9 based on the valve end connector size. table 9—minimum duration of hydrostatic shell tests. #api6d#valves#valvetesting#pipeline#hydrotestwelcome to everything valves. this channel is dedicated to bringing you only industrial valve knowledge.in today.

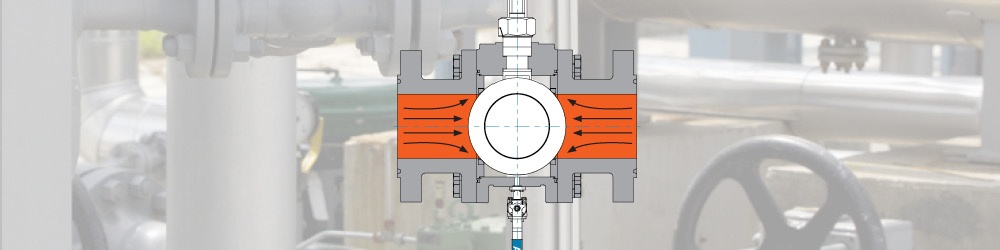

Valve Hydro Testing And Repair Valve Pressure Testing Valve Repair Scope: api 6d trunnion mounted ball valves. 2. process. the test bed must allow all the required pressures to be reached (1.5 x pn) and incorporate all the necessary accessories for the correct running of the tests: vents, water and air connections, manometers, receptacles with the necessary quantity of water, etc. A. 150% of the max pressure rating. b. 150% of the max pressure rating. c. 150% of the max pressure rating. shell hydrostatic test is carried out with half opened valve. hydraulic. 5 min. a. atmospheric. b. atmospheric. c. 110% of the max pressure rating. There are three types of tests required under api 6d: stem backseat test. hydrostatic shell test. hydrostatic seat test. for valves up to 16” x 300 lbs, we can perform these tests using our barbee tf 100 daq test stand. we have tested up to 24” 900# in the shop, and we can test larger valves with bolt on flanges into the valve. The document provides testing instructions for api 6d ball valves. it outlines 4 types of tests: [1] shell hydrostatic pressure testing to test casing integrity, [2] hydrostatic testing of seats to test for leaks, [3] optional pneumatic testing of seats, and [4] special testing if required. it provides minimum test pressures, times and acceptance criteria for each test based on valve rating.

Api 6d Testing Procedure Double Block Bleed Versus Double There are three types of tests required under api 6d: stem backseat test. hydrostatic shell test. hydrostatic seat test. for valves up to 16” x 300 lbs, we can perform these tests using our barbee tf 100 daq test stand. we have tested up to 24” 900# in the shop, and we can test larger valves with bolt on flanges into the valve. The document provides testing instructions for api 6d ball valves. it outlines 4 types of tests: [1] shell hydrostatic pressure testing to test casing integrity, [2] hydrostatic testing of seats to test for leaks, [3] optional pneumatic testing of seats, and [4] special testing if required. it provides minimum test pressures, times and acceptance criteria for each test based on valve rating. 7 1. hydrostatic shell test with the valve kept half open, fill the body with water and apply test pressure shown in table 2. make sure that the connections are tight then use leak detector spray on all body joins & body surfaces to ensure zero leakage and all parts are free from leakage. Inspection & test procedure. 1 scope this standard provides specific inspection items to be performed on all ball & plug valves. the valves shall be provided with a serial numbering system and will be documented for traceability purposes. 1.1 valve range. type : floating & trunnion ball & lubricated plug. body: split body 2p & 3p and top entry.

Api 6d Check Valve Seat And Shell Testing Global Valve And Controls 7 1. hydrostatic shell test with the valve kept half open, fill the body with water and apply test pressure shown in table 2. make sure that the connections are tight then use leak detector spray on all body joins & body surfaces to ensure zero leakage and all parts are free from leakage. Inspection & test procedure. 1 scope this standard provides specific inspection items to be performed on all ball & plug valves. the valves shall be provided with a serial numbering system and will be documented for traceability purposes. 1.1 valve range. type : floating & trunnion ball & lubricated plug. body: split body 2p & 3p and top entry.

Api 6d Check Valve Api 6d Swing Wafer Check Valves Suppliers In Uae

Api6d Testing Procedure Double Block Bleed Versus Double Isolation

Comments are closed.