Api 6a Valve Testing Procedure Wellhead Valve Hydro Testing How To

Api 6a Valve Testing Procedure Wellhead Valve Hydro Testing How To #valves#oilfieldvalvewelcome back to everything valves. the channel dedicated to brining you everything valves. thank to everyone supporting this channel. if. The api 6a specification requires manufacturers to conduct a series of tests in order to verify the component. below is a summary of the typical sequence of tests carried out for api 6a. 1. valve and actuator pre qualification tests for api 6a. actuator factory acceptance test (fat) valve factory acceptance test (fat) 2. valve pr2 test for api 6a.

Api 6a Hydro Test Psl 1 Wellhead Gate Valve Hydro Test How To #valves #oilfieldvalve #api6awelcome to everything valves. the channel dedicated to everything valves. thanks you to everyone supporting the channel. if you. Testing and quality control api 6a mandates rigorous testing procedures to verify the integrity of each component. testing includes pressure testing, thermal cycling, and material verification to confirm equipment performance under operational stress. manufacturers must maintain quality control systems to ensure consistent compliance with api 6a. Specification 6a also serves as the reference source for the design of flanged end and outlet connections for use at 2,000 to 20,000 psi maximum rated working pressures and a family of gate valves for use over these same pressure ranges api specification 6a is also specified as the base standard for manufacture of subsea equipment in. 2.2.1 api specification 6a – annex j.1 annex j defines the requirements for repair and remanufacture of user purchaser owned wellhead and christmas tree equipment originally manufactured in accordance with this international standard for continued service by the user purchaser. 2.2.2 api specification 6a – annex j.2.1.

Valve Hydro Testing And Repair Valve Pressure Testing Valve Repair Specification 6a also serves as the reference source for the design of flanged end and outlet connections for use at 2,000 to 20,000 psi maximum rated working pressures and a family of gate valves for use over these same pressure ranges api specification 6a is also specified as the base standard for manufacture of subsea equipment in. 2.2.1 api specification 6a – annex j.1 annex j defines the requirements for repair and remanufacture of user purchaser owned wellhead and christmas tree equipment originally manufactured in accordance with this international standard for continued service by the user purchaser. 2.2.2 api specification 6a – annex j.2.1. Yarmouth is available for your testing needs for wellhead and drilling equipment. we have been performing api 6a – pr2f, and api 16c testing for several years. our current pressure capability is 25,000 psig hydro and 20,000 psig gas. our custom software and controls ensure that all test parameters are maintained throughout the entire procedure. Figure 1. test procedure (source: api 6a specification 20th edition) a third party test house is used for carrying out the pressure and temperature tests, physically testing whether the product withstands the temperature and pressure specifications. upon completion, a certificate is given to prove that the equipment has passed.

Api 6a Wellhead Casing Head Choke Valve Butterfly Gate Globe Ball Yarmouth is available for your testing needs for wellhead and drilling equipment. we have been performing api 6a – pr2f, and api 16c testing for several years. our current pressure capability is 25,000 psig hydro and 20,000 psig gas. our custom software and controls ensure that all test parameters are maintained throughout the entire procedure. Figure 1. test procedure (source: api 6a specification 20th edition) a third party test house is used for carrying out the pressure and temperature tests, physically testing whether the product withstands the temperature and pressure specifications. upon completion, a certificate is given to prove that the equipment has passed.

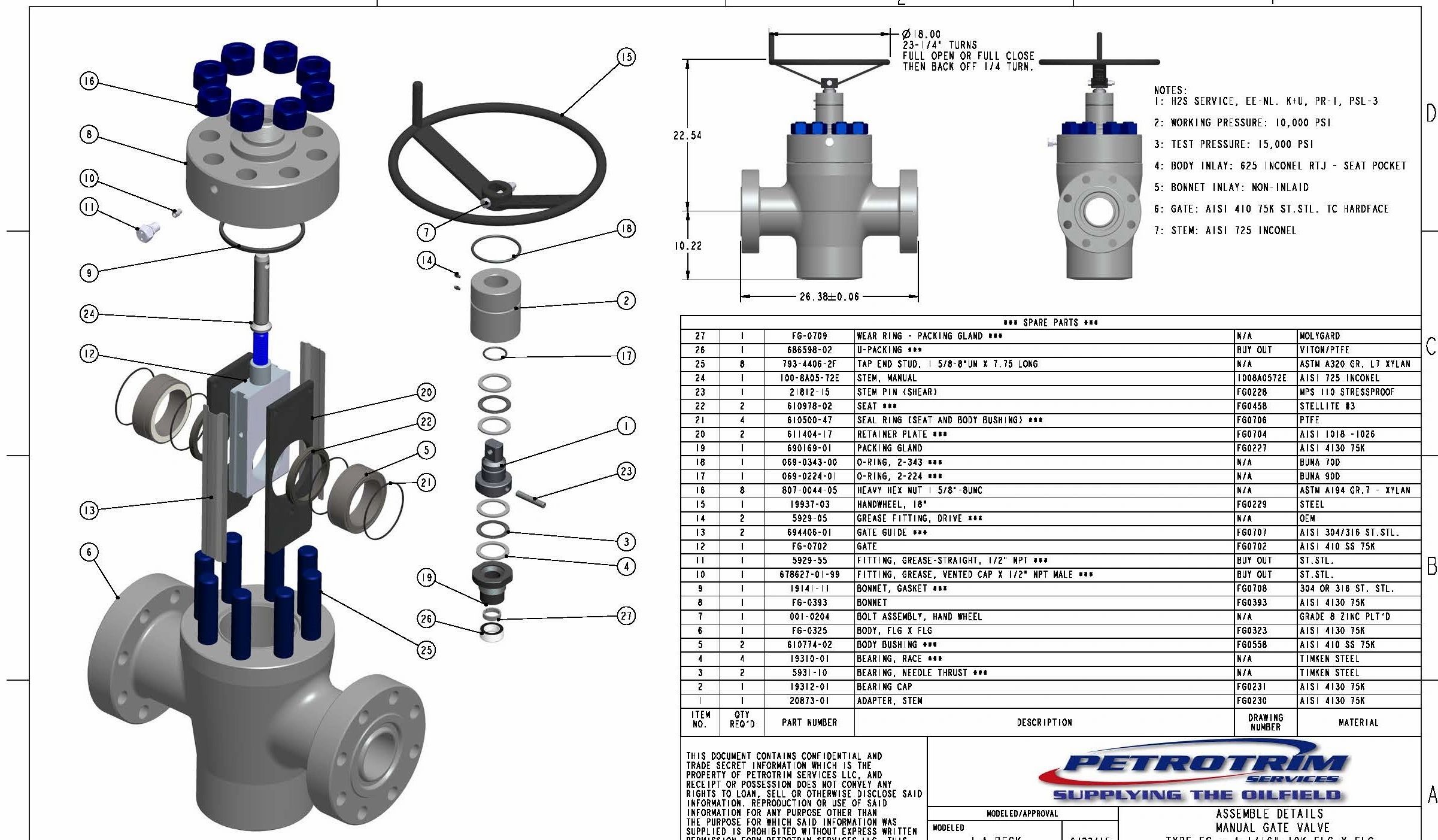

Petrotrim Services Api 6a Gate Valve Oil And Gas

Comments are closed.