An Overview Of The Refining Process

What Is The Process Of Crude Oil Refining Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products. petroleum refineries are complex and expensive industrial facilities. all refineries have three basic steps: separation. conversion. treatment. Ever wondered how an oil refinery works? now you can learn more about the technology involved in refining crude oil into the thousands of petroleum based pro.

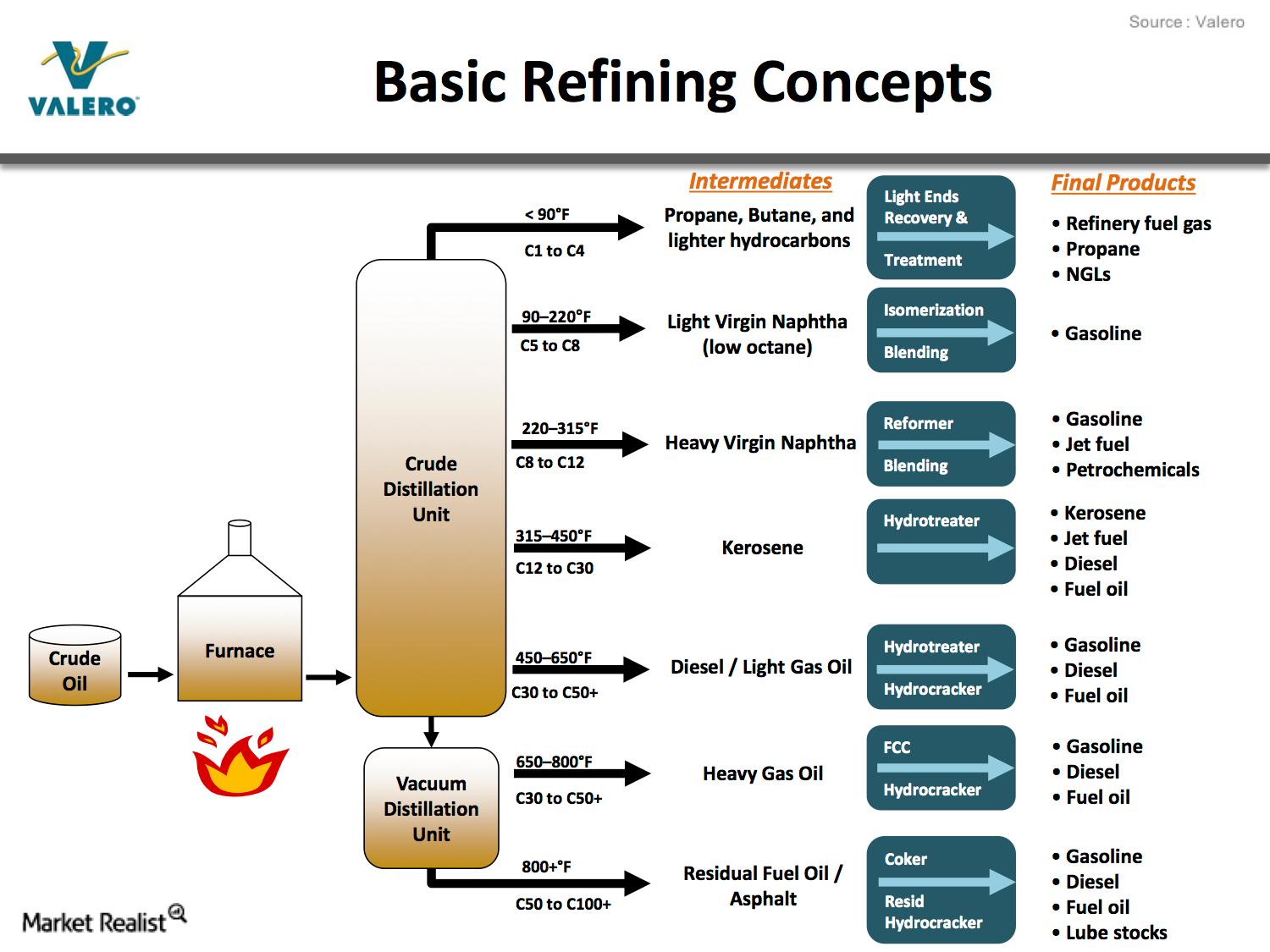

Illustration Of A Crude Oil Refining Stages Of Processing Crude Oil On In the u.s. refineries, a principal focus is on the production of gasoline because of high demand. diesel fuel is the principal refinery product in most other parts of the world. figure 1.4 shows a typical distribution of products from a barrel of crude oil in a u.s. refinery. distillation process separates the crude oil into boiling point. The refining of crude petroleum owes its origin to the successful drilling of the first oil wells in ontario, canada, in 1858 and in titusville, pennsylvania, u.s., in 1859. prior to that time, petroleum was available only in very small quantities from natural seepage of subsurface oil in various areas throughout the world. Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as liquefied petroleum gas (lpg), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils. [1][2][3] refineries and petroleum. The first process is known as distillation. in this process, crude oil is heated and fed into a distillation column. a schematic of the distillation column is shown in figure 2.2 f i g u r e 2.2. as the temperature of the crude oil in the distillation column rises, the crude oil separates itself into different components, called “fractions.”.

An Overview Of The Refining Process Youtube Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as liquefied petroleum gas (lpg), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils. [1][2][3] refineries and petroleum. The first process is known as distillation. in this process, crude oil is heated and fed into a distillation column. a schematic of the distillation column is shown in figure 2.2 f i g u r e 2.2. as the temperature of the crude oil in the distillation column rises, the crude oil separates itself into different components, called “fractions.”. Reforming. the process of reforming was developed to raise both the quality and volume of gasoline produced by refiners. using a catalyst again, after a series of reforming processes, substances are converted into aromatics and isomers, which have much higher octane numbers than the paraffins and napthenes produced by other refinery processes. Refining process snapshot. 1. shipping. we acquire 2.2 million barrels of crude oil a day from suppliers. the crude is shipped to our refineries via pipeline, rail, trucks, or ships and barges. 2. storage. the crude is stored in our refineries, which have a capacity to store 26.2 million barrels. 3.

A Look Into The Refining Process Reforming. the process of reforming was developed to raise both the quality and volume of gasoline produced by refiners. using a catalyst again, after a series of reforming processes, substances are converted into aromatics and isomers, which have much higher octane numbers than the paraffins and napthenes produced by other refinery processes. Refining process snapshot. 1. shipping. we acquire 2.2 million barrels of crude oil a day from suppliers. the crude is shipped to our refineries via pipeline, rail, trucks, or ships and barges. 2. storage. the crude is stored in our refineries, which have a capacity to store 26.2 million barrels. 3.

Oil Refinery Process Infographic Crude Royalty Free Vector

Comments are closed.