6 Sigma Dmaic Process

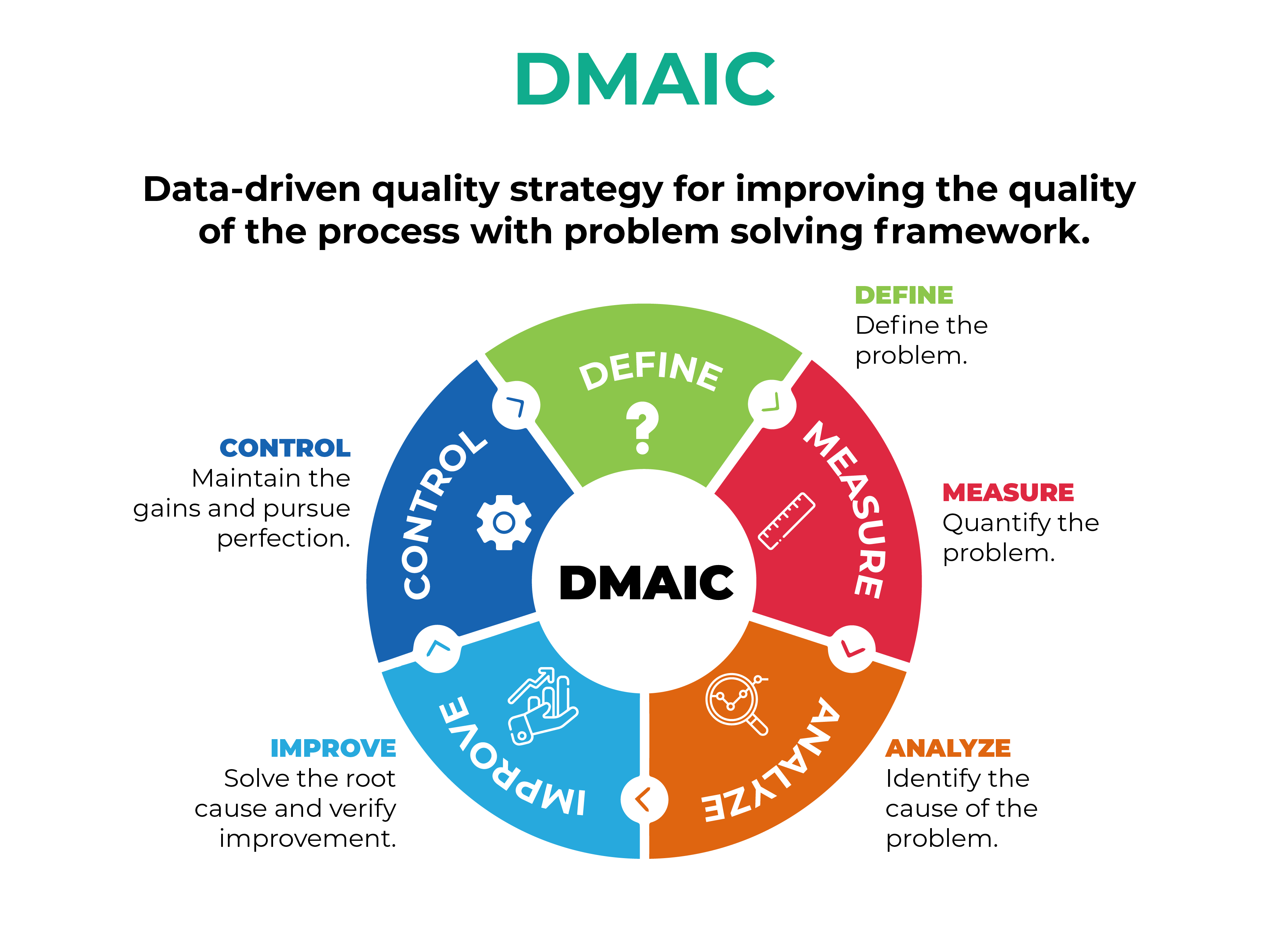

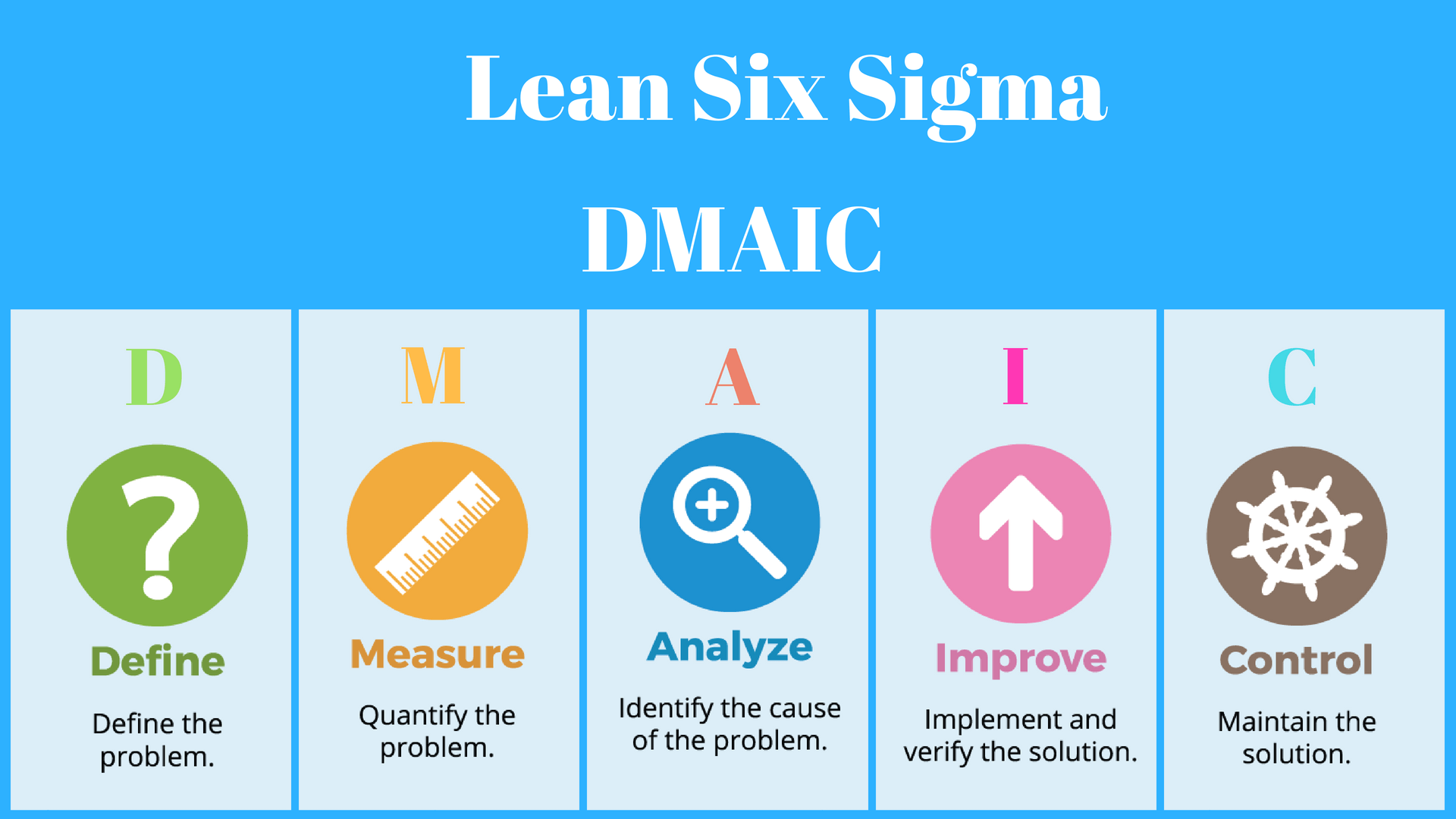

What Are The 5 Phases Of Lean Six Sigma Dmaic is the problem solving approach that drives lean six sigma. it’s a five phase method—define, measure, analyze, improve and control—for improving existing process problems with unknown causes. dmaic is based on the scientific method and it’s pronounced “duh may ik.”. to build your understanding of the method, and help you apply. The define measure analyze improve control (dmaic) process. quality glossary definition: dmaic. dmaic is a data driven quality strategy used to improve processes. it is an integral part of a six sigma initiative, but in general can be implemented as a standalone quality improvement procedure or as part of other process improvement initiatives.

How Is Lean Six Sigma Dmaic Process Defined One of the core techniques behind any process improvement, particularly in six sigma, is dmaic. this handy approach, pronounced duh may ik, is the key to employing six sigma we all like to know about the broader philosophies behind process improvements, but sometimes we need to knuckle down and look at some of the more technical details. The six sigma dmaic process is an effective tool that can be used in any industry. it gives businesses the ability to analyze and improve their processes, leading to better results. by reviewing the example and following the five steps of the dmaic process – define, measure, analyze, improve and control – businesses can create meaningful. What is dmaic. dmaic is an acronym for the stages of a lean six sigma improvement methodology, which stands for define, measure, analyze, improve and control. these 5 steps provide a structured way to convert process inputs into more valuable outputs. each of the 5 steps occurs in the defined order and each step builds upon the last working. Dmaic (define, measure, analyze, improve, and control) is a powerful lean six sigma improvement methodology that is frequently used by certified green belts and above. the acronym represents the process’s five phases, providing a clear sequence of steps to take and ensuring that projects are well defined and improvements are founded on.

What Is Dmaic Process News What is dmaic. dmaic is an acronym for the stages of a lean six sigma improvement methodology, which stands for define, measure, analyze, improve and control. these 5 steps provide a structured way to convert process inputs into more valuable outputs. each of the 5 steps occurs in the defined order and each step builds upon the last working. Dmaic (define, measure, analyze, improve, and control) is a powerful lean six sigma improvement methodology that is frequently used by certified green belts and above. the acronym represents the process’s five phases, providing a clear sequence of steps to take and ensuring that projects are well defined and improvements are founded on. The dmaic methodology is a systematic and data driven approach that empowers organizations to achieve process excellence and continuous improvement. by defining problems, measuring performance, analyzing root causes, implementing improvements, and establishing control measures, lean six sigma practitioners can transform complex challenges into. The dmaic methodology consists of five phases: define, measure, analyze, improve, and control. these phases form the pillars of the dmaic framework, allowing us to improve an existing business function or an entire organization to achieve improvement and effectiveness. the dmaic process is data driven and drives through every intricate detail.

Comments are closed.