5 Qualities Of Excellent Pipe Flanges Forged Components Inc

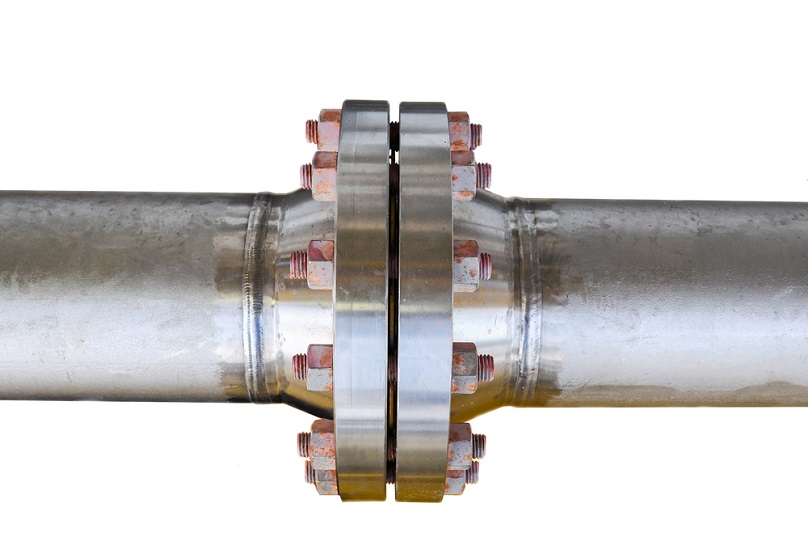

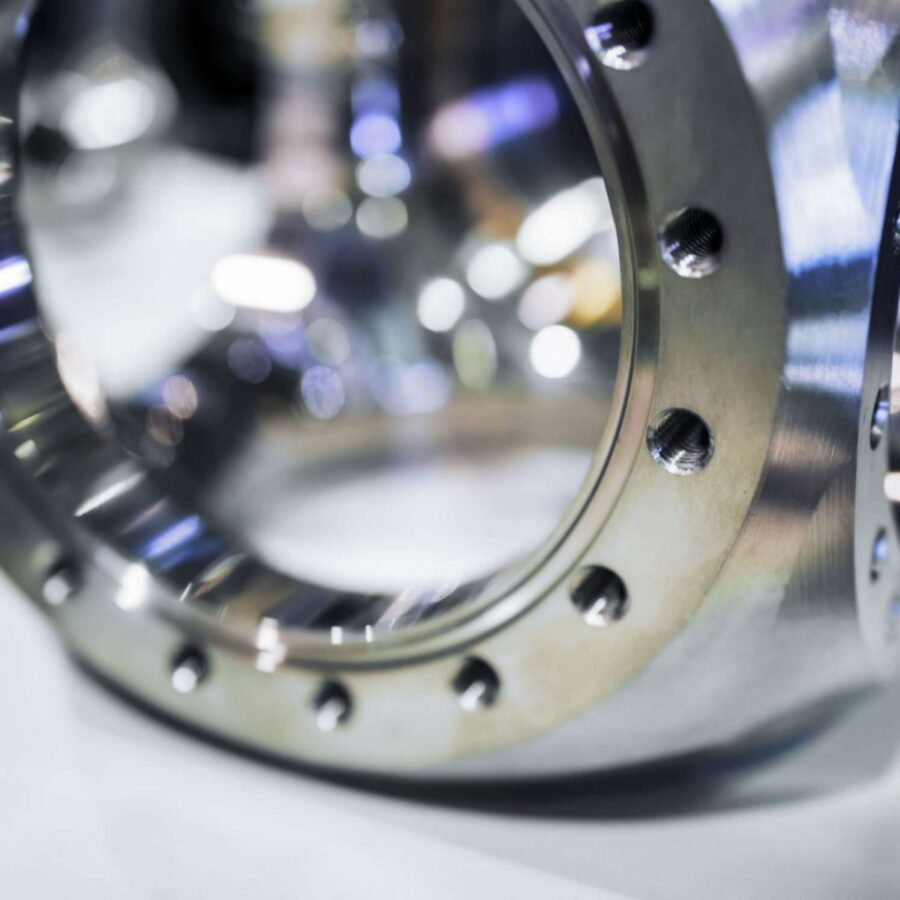

5 Qualities Of Excellent Pipe Flanges Forged Components Inc Forged components inc. 5 qualities of excellent pipe flanges a pipe flange is an important part of any pipeline system and needs to be high quality in order to meet the demanding environment these forged components live in. Key manufacturing qualities of forged flanges. material strength: forged flanges are known for their exceptional strength, primarily due to the forging process that alters the grain structure of the metal, enhancing its mechanical properties. corrosion resistance: they are manufactured using materials that offer excellent corrosion resistance.

5 Qualities Of Excelent Pipe Flanges Forged weld neck flanges. weld neck flanges are a type of flange that are characterized by their long, tapered neck, which provides excellent reinforcement in high pressure and high temperature applications due to their reliability and mechanical strength. forged components is the industry leader in the manufacturing of weld neck connection. Here are some common types of industrial forged flanges: weld neck flanges: recognized by their long tapered necks, weld neck flanges are welded to the pipe. slip on flanges: these flanges are. 15. forged components inc. 5,273 followers. 1mo. the forged components quality management system is a process for monitoring the quality of manufacturing throughout the delivery of our forged. Pipe flanges that are made to standards called out by asme b16.5 or asme b16.47, and mss sp 44. they are typically made from forged materials and have machined surfaces. asme b16.5 refers to nominal pipe sizes (nps) from 1⁄2" to 24". b16.47 covers npss from 26" to 60".

News Forged Components Inc 15. forged components inc. 5,273 followers. 1mo. the forged components quality management system is a process for monitoring the quality of manufacturing throughout the delivery of our forged. Pipe flanges that are made to standards called out by asme b16.5 or asme b16.47, and mss sp 44. they are typically made from forged materials and have machined surfaces. asme b16.5 refers to nominal pipe sizes (nps) from 1⁄2" to 24". b16.47 covers npss from 26" to 60". Generally, forged flanges are stronger and more reliable than cast flanges because the grain flows of the steel are altered, confirming to the shape of the part. the tight grain structure of forgings makes the pieces mechanically stronger, and more resistant to general wear and tear than cast flanges. the higher quality, reliability, strength. 2. socket weld flanges. socket weld flanges are a good fit for smaller sizes of high pressure pipes. to develop a joint connection, insert the pipe into the female socket of socket weld flanges, and then fillet weld is applied around the top. this robust connection allows a smooth flow of liquid or gas in the pipe.

News Forged Components Inc Generally, forged flanges are stronger and more reliable than cast flanges because the grain flows of the steel are altered, confirming to the shape of the part. the tight grain structure of forgings makes the pieces mechanically stronger, and more resistant to general wear and tear than cast flanges. the higher quality, reliability, strength. 2. socket weld flanges. socket weld flanges are a good fit for smaller sizes of high pressure pipes. to develop a joint connection, insert the pipe into the female socket of socket weld flanges, and then fillet weld is applied around the top. this robust connection allows a smooth flow of liquid or gas in the pipe.

Pipe Flanges Archives Forged Components Inc

Comments are closed.