3d Printing Comparison Multi Jet Fusion Vs Selective Laser Sintering Nylon Fictiv

3d Printing Comparison Multi Jet Fusion Vs Selective Laser Sintering Sls 3d printing. selective laser sintering (sls), on the other hand, also builds parts layer by layer by fusing a powder bed. however, it employs a high powered laser to sinter the nylon powder, selectively fusing particles to form a solid structure. sls is known for its ability to create strong, functional parts with complex geometries. Multi jet fusion, or mjf, and selective laser sintering, or sls, both utilize nylon material. here's an overview of the difference between each in terms of r.

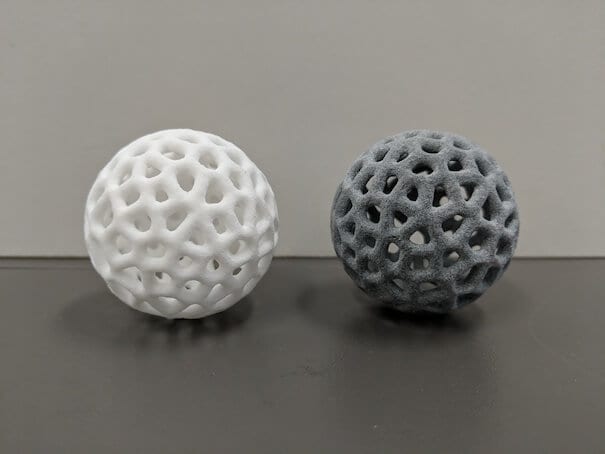

Ultimate Comparison Between Multi Jet Fusion Vs Sls Technology 3d printing technologies comparison: multi jet fusion vs. selective laser sintering. selective laser sintering (sls) and multi jet fusion (mjf) are both powder bed fusion 3d printing technologies. selective laser sintering has been in market since 1992, and multi jet fusion has come on the scene in recent years. Multi jet fusion parts will have a finer feature resolution of 0.020 in. (0.51mm) compared to 0.030 in. (0.762mm) for sls. although, it should be noted that sls has better small feature accuracy of ±0.001 (0.0254mm) over ±0.004 in. (0.1016mm) for mjf. if a smooth surface finish is a requirement, mjf will be a better choice than sls. Higher detail: mjf. multi jet fusion can produce parts with higher levels of detail and higher resolution (1200 dpi). however, sls offers slightly higher dimensional accuracy. using pa 12, sls provides a dimensional accuracy of .03% for parts above 100 mm. mjf offers .05% in comparison. larger parts: sls. Sls and mjf are powder bed fusion technologies that create 3d parts from a thermoplastic powder. selective laser sintering (sls) uses a laser to melt and fuse powder grains, whereas multi jet fusion (mjf) employs a fusing agent, heat, and infrared light to fuse the powder. sls can employ a more comprehensive selection of materials – many of.

Multi Jet Fusion Mjf Vs Selective Laser Sintering Sls Higher detail: mjf. multi jet fusion can produce parts with higher levels of detail and higher resolution (1200 dpi). however, sls offers slightly higher dimensional accuracy. using pa 12, sls provides a dimensional accuracy of .03% for parts above 100 mm. mjf offers .05% in comparison. larger parts: sls. Sls and mjf are powder bed fusion technologies that create 3d parts from a thermoplastic powder. selective laser sintering (sls) uses a laser to melt and fuse powder grains, whereas multi jet fusion (mjf) employs a fusing agent, heat, and infrared light to fuse the powder. sls can employ a more comprehensive selection of materials – many of. When 3d printing with the selective laser sintering or multi jet fusion process, you must choose the material properties that will fit your project. these 3d printing processes are consumer products, architectural models , drones , robotics , luxury , automotive , medical , iot devices, sports equipments , footwear, orthopedic technology. Selective laser sintering. selective laser sintering is a powder bed 3d printing technique used for creating parts from thermoplastic materials such as pa 12 and pa 11. this process involves a co2 laser selectively fusing plastic powder by tracing each cross section of the part, layer by layer.

3d Printing Technologies Comparison Multi Jet Fusion Vs Selective When 3d printing with the selective laser sintering or multi jet fusion process, you must choose the material properties that will fit your project. these 3d printing processes are consumer products, architectural models , drones , robotics , luxury , automotive , medical , iot devices, sports equipments , footwear, orthopedic technology. Selective laser sintering. selective laser sintering is a powder bed 3d printing technique used for creating parts from thermoplastic materials such as pa 12 and pa 11. this process involves a co2 laser selectively fusing plastic powder by tracing each cross section of the part, layer by layer.

Multi Jet Fusion Mjf Vs Selective Laser Sintering Sls

Comments are closed.