3d Printing Comparison Multi Jet Fusion Vs Selective Laser Sintering

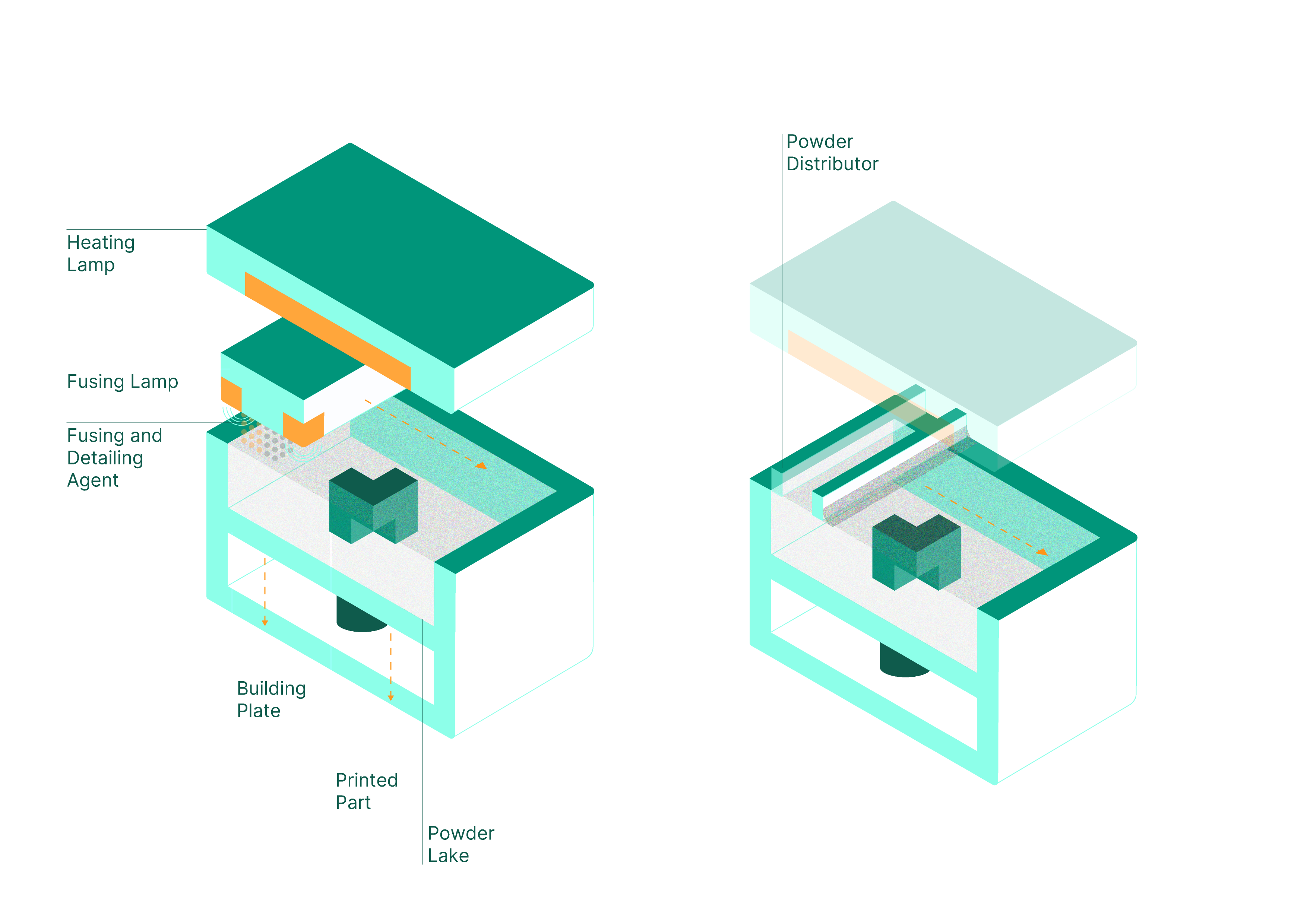

3d Printing Comparison Multi Jet Fusion Vs Selective Laser Sintering Multi jet fusion (mjf) and selective laser sintering (sls) are industrial 3d printing technologies that belong to the powder bed fusion family. both processes build parts by thermally fusing (or sintering) polymer powder particles layer by layer. Sls and mjf are powder bed fusion technologies that create 3d parts from a thermoplastic powder. selective laser sintering (sls) uses a laser to melt and fuse powder grains, whereas multi jet fusion (mjf) employs a fusing agent, heat, and infrared light to fuse the powder. sls can employ a more comprehensive selection of materials – many of.

Multi Jet Fusion Vs Selective Laser Sintering Makerverse Selective laser sintering can produce thicker parts than mjf. if this is essential to the form and functionality of your part, then sls has the advantage. higher detail: mjf. multi jet fusion can produce parts with higher levels of detail and higher resolution (1200 dpi). however, sls offers slightly higher dimensional accuracy. 3d printing technologies comparison: multi jet fusion vs. selective laser sintering. selective laser sintering (sls) and multi jet fusion (mjf) are both powder bed fusion 3d printing technologies. selective laser sintering has been in market since 1992, and multi jet fusion has come on the scene in recent years. Multi jet fusion parts will have a finer feature resolution of 0.020 in. (0.51mm) compared to 0.030 in. (0.762mm) for sls. although, it should be noted that sls has better small feature accuracy of ±0.001 (0.0254mm) over ±0.004 in. (0.1016mm) for mjf. if a smooth surface finish is a requirement, mjf will be a better choice than sls. When 3d printing with the selective laser sintering or multi jet fusion process, you must choose the material properties that will fit your project. these 3d printing processes are consumer products, architectural models , drones , robotics , luxury , automotive , medical , iot devices, sports equipments , footwear, orthopedic technology.

Ultimate Comparison Between Multi Jet Fusion Vs Sls Technology Multi jet fusion parts will have a finer feature resolution of 0.020 in. (0.51mm) compared to 0.030 in. (0.762mm) for sls. although, it should be noted that sls has better small feature accuracy of ±0.001 (0.0254mm) over ±0.004 in. (0.1016mm) for mjf. if a smooth surface finish is a requirement, mjf will be a better choice than sls. When 3d printing with the selective laser sintering or multi jet fusion process, you must choose the material properties that will fit your project. these 3d printing processes are consumer products, architectural models , drones , robotics , luxury , automotive , medical , iot devices, sports equipments , footwear, orthopedic technology. Multi jet fusion parts will have a finer feature resolution 0.5mm compared to 0.75mm for sls. although, it should be noted that sls has better small feature accuracy of ±0.025mm over ±0.10 for mjf. if a smooth surface finish is a requirement, mjf will be a better choice than sls. Suppose you plan to use powder bed fusion to manufacture your parts. both multi jet fusion and selective laser sintering 3d printing technologies have benefits and drawbacks; we recommend you consider the following when selecting a manufacturing method. the powder bed technologies are comparable in performance, and on average, the prices are.

Comments are closed.