3d Printed Nylon Pa11 Vs Pa12 Hp Multi Jet Fusion 3d Printing Printed By Printing Portal Uk

Unterschiede Zwischen Nylon Pa 11 Pa 12 Und Hp Mjf Quick demo of the higher ductility of nylon pa11 compared to the more brittle nylon pa12.pa12 parts printed on a hp5210 pa11 parts from a 4210.printingportal. Googles designed by boltian and 3d printed with hp multi jet fusion 5210 on pa12. finish: unrefined grey. based on development methods, pa11 clearly has a lower environmental impact and does not require tons of non renewable substances in order to be produced. furthermore, it is superior in its thermal resistance, stable in light and weather.

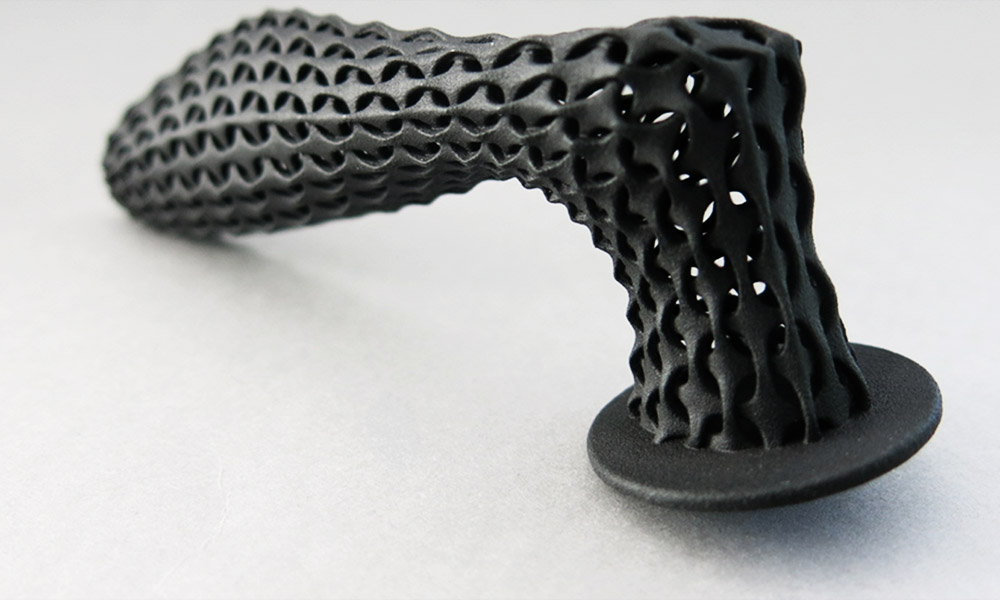

3d Printed Nylon Pa11 Vs Pa12 Hp Multi Jet Fusion 3d Printing Nylon pa12 has many manufacturers which include arkema and evonik, whereas pa11 is only manufactured by arkema. multijet fusion pa12 is a specific type of fine pa12 polyamide powder. produced by hp, this material, which is also called 3d high reusability pa12, is optimized for the multi jet fusion technology to produce fully functioning parts. However, there are a variety of types of nylon used for 3d printing, the two most common being nylon pa11 and nylon pa12. this article explains the key differences between the two when 3d printed with hp multi jet fusion 3d printing technology. Sls (selective laser sintering) and mjf (multi jet fusion) are two of the most common 3d printing technologies used with pa11 and pa12. sls uses a laser to sinter polymer powder , layer by layer, to create the desired object. It is highly resistant to abrasion and fatigue, and pa11 parts boast higher isotropy. it withstands temperatures of up to 190°c, even though permanent temperatures range from 40°c to 125°c. finished pa11 parts are both strong and flexible, durable and have an opaque matte surface. the same is true of pa12 parts.

Pa12 Vs Pa11 What Are The Differences Sls (selective laser sintering) and mjf (multi jet fusion) are two of the most common 3d printing technologies used with pa11 and pa12. sls uses a laser to sinter polymer powder , layer by layer, to create the desired object. It is highly resistant to abrasion and fatigue, and pa11 parts boast higher isotropy. it withstands temperatures of up to 190°c, even though permanent temperatures range from 40°c to 125°c. finished pa11 parts are both strong and flexible, durable and have an opaque matte surface. the same is true of pa12 parts. Hp’s jet fusion 300 and 500 3d printers can only print nylon pa12, with other printers only able to print tpu, pa11 and pa12. nylon is a fantastic printing material with engineering grade properties, so being restricted to just nylon isn’t the worst possible situation. you’re still able to create great prints with strong mechanical. Hp multi jet fusion material pa12: properties and characteristics. for a material made from recycled cooking oil, hp mjf pa12 white has some pretty great characteristics that make it ideal for 3d printing — it’s super strong, has a great finish, is water tight, and its biocompatible.

3d Printing On Pa12 Nylon With Hp Multi Jet Fusion Youtube Hp’s jet fusion 300 and 500 3d printers can only print nylon pa12, with other printers only able to print tpu, pa11 and pa12. nylon is a fantastic printing material with engineering grade properties, so being restricted to just nylon isn’t the worst possible situation. you’re still able to create great prints with strong mechanical. Hp multi jet fusion material pa12: properties and characteristics. for a material made from recycled cooking oil, hp mjf pa12 white has some pretty great characteristics that make it ideal for 3d printing — it’s super strong, has a great finish, is water tight, and its biocompatible.

Nylon Pa12 And Nylon Pa11 What Is The Difference

Comments are closed.